Three-dimensional model testing system and method of tunnel water outburst and mud outburst and grouting treatment

A test system and three-dimensional model technology, which is applied to the three-dimensional model test system and its test field for the treatment of tunnel water and mud inrush and grouting, which can solve the problems of no grouting process research and no post-disaster treatment research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

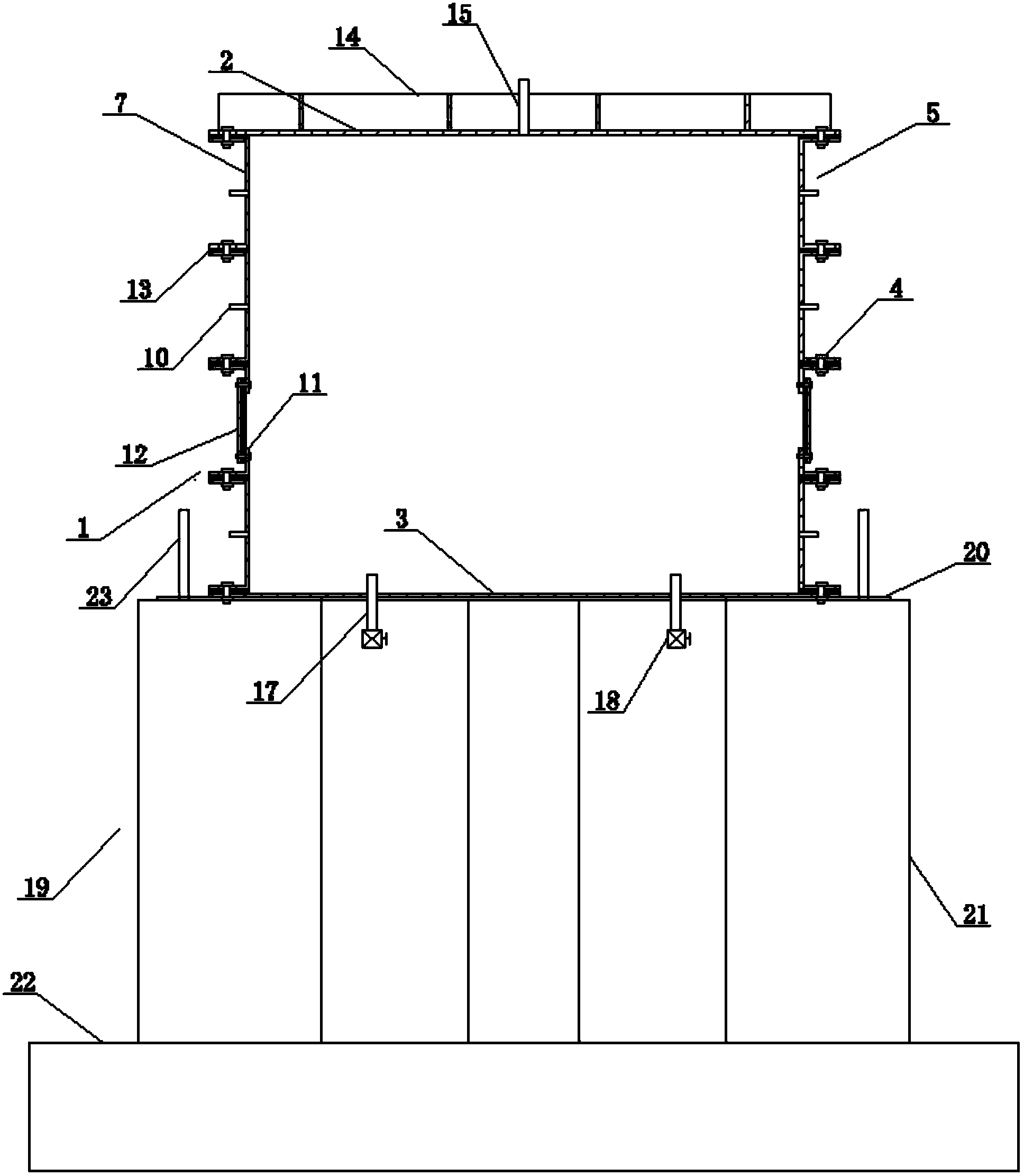

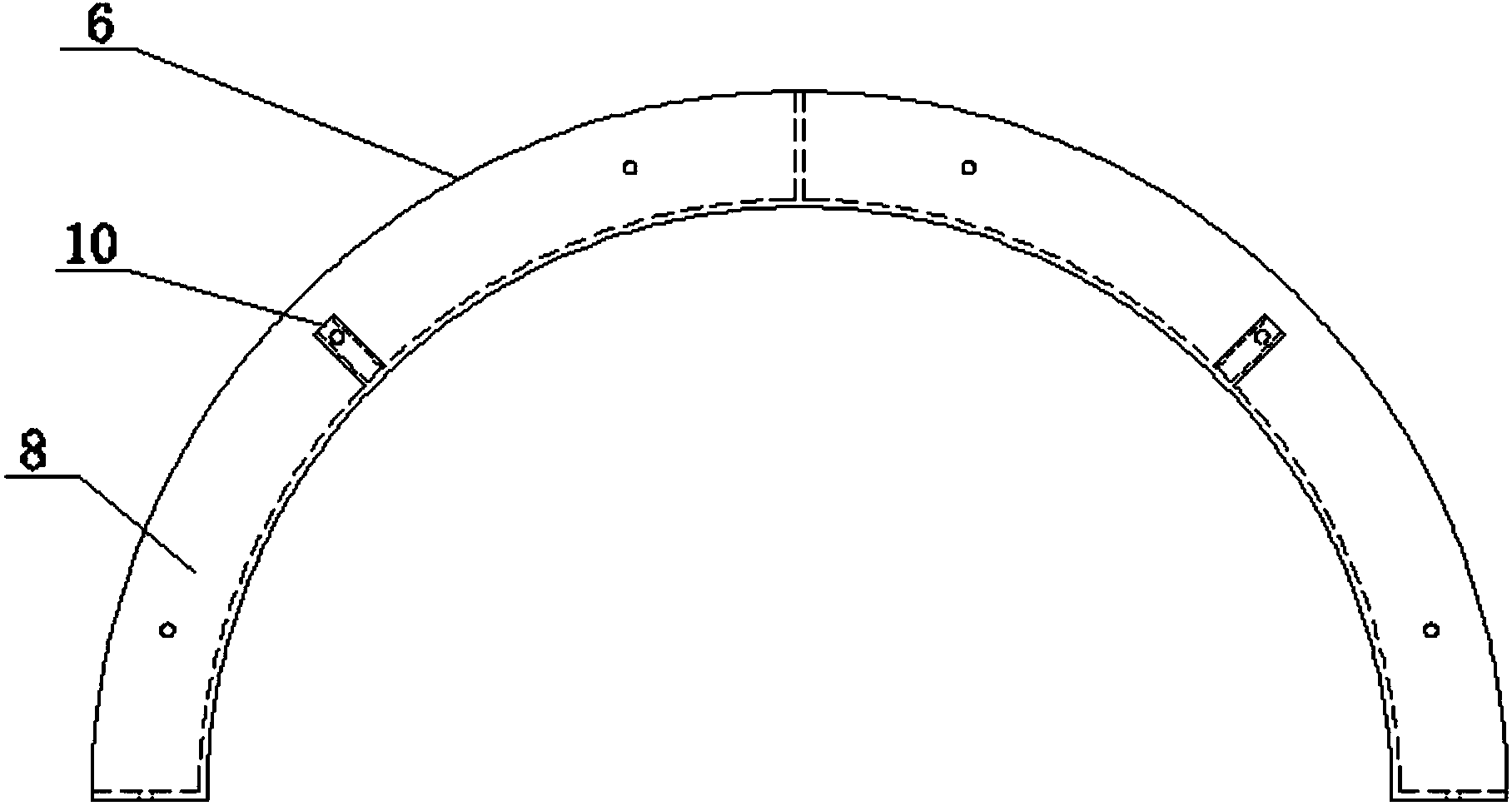

[0072] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0073] Such as Figure 1-Figure 14 As shown, the design height of the experimental model needs to connect the four-layer model ring unit, and the tunnel position is at the diameter of the second-layer model ring unit. Without in-situ stress, the surrounding rock medium is in direct contact with the outside world. The surrounding rock medium is strongly weathered clay, and the fault medium is a mixture of water-rich and weak fault mud and stone in the original state. The fault dip angle is 70° and the fault thickness is 60cm. Such geological conditions can easily lead to water and mud inrush disasters during tunnel excavation. occur.

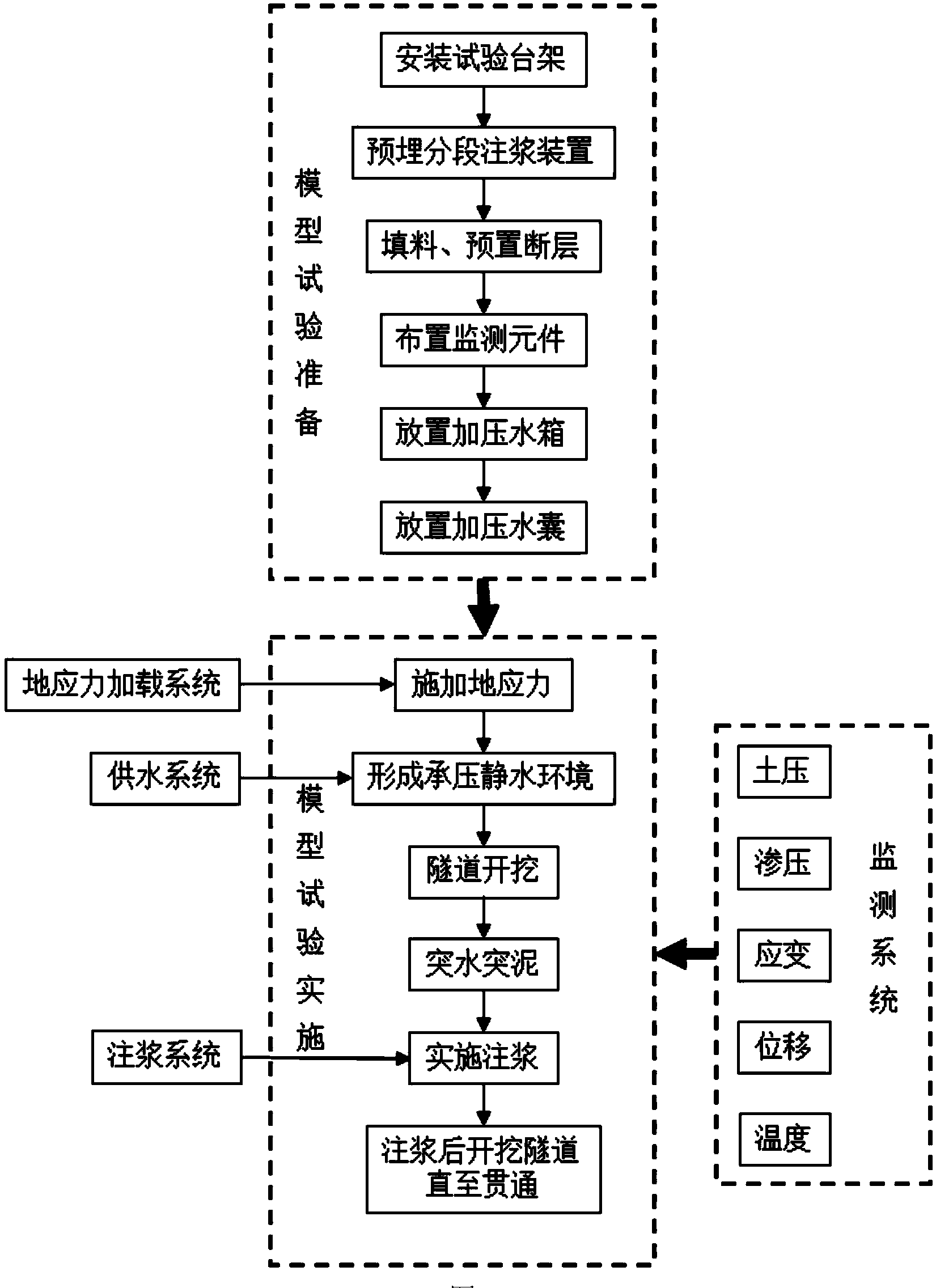

[0074] The model test system can completely and continuously simulate the evolution of tunnel water and mud inrush disasters under complex geological conditions, post-disaster grouting treatment and tunnel excavation pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com