A multi-degree-of-freedom precision adjustment mechanism

A technology of precise adjustment and degrees of freedom, applied in the field of lithography, it can solve the problems of many stacking combinations, complex structures, incomplete adjustment and decoupling, etc., to achieve the effect of small space, reduction of quantity, and elimination of over-constraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

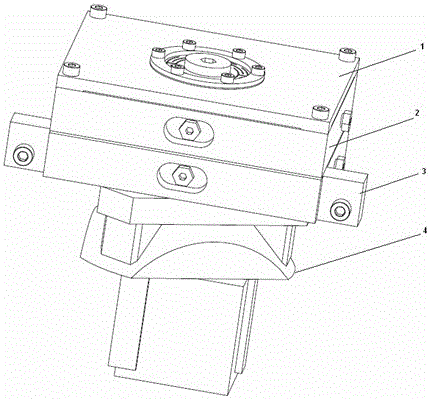

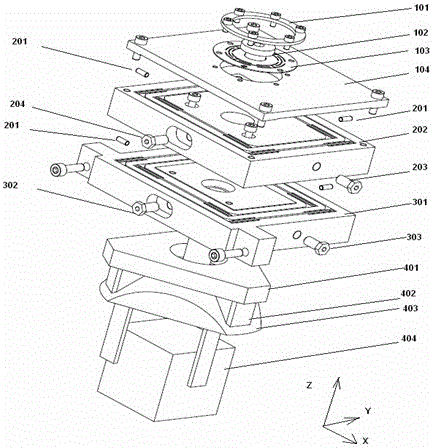

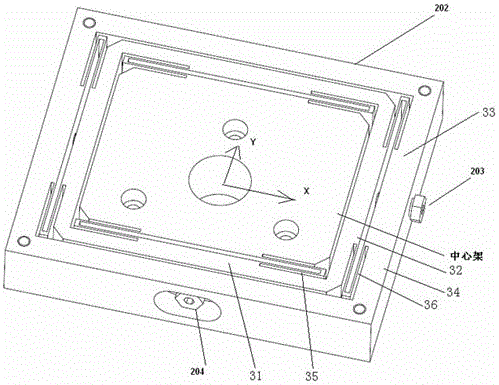

[0028] Such as figure 1 As shown, the multi-degree-of-freedom precision adjustment mechanism according to the present invention is mainly composed of four parts, including a connection structure 1 , an inclined flexible support structure 2 , a displacement flexible support structure 3 and a fixing mechanism 4 . Among them, the displacement flexible support structure 3 provides micro-displacement adjustments in the X and Y directions, and the inclined flexible support structure 2 provides Rx, Ry tilt direction adjustments, which are converted into angle adjustments through micro-displacements, and the fixed structure 4 is equipped with an adjusted element 404 . The connection structure 1 realizes the connection of the fixed structure 4 and the rotation adjustment in the Rz direction.

[0029] figure 2 An exploded schematic view of the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com