Novel quartz boat suitable for atmospheric pressure furnace

A technology for quartz boats and pressure furnaces, applied in the field of new structures, which can solve problems such as the expansion of the gap between the slot rods 10, the damage and deformation of silicon wafers and quartz boat transmission manipulators, etc., to reduce production costs, prevent damage to equipment, and prolong deformation. cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

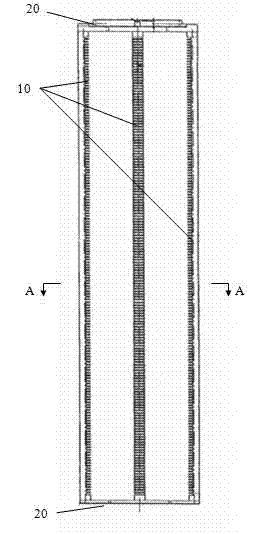

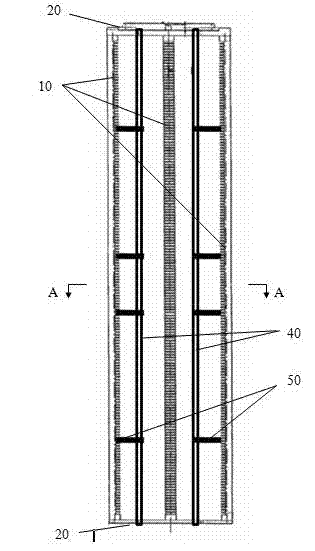

[0019] Cooperate see image 3 , Figure 4 As shown, in a kind of quartz boat provided by the present invention, on the basis of the original structure, several auxiliary struts 40 connected between the two frames 20 of the quartz boat are added, and several auxiliary struts 40 connected between the auxiliary struts 40 and corresponding grooves are added. A plurality of support bars 50 between the bars 10 .

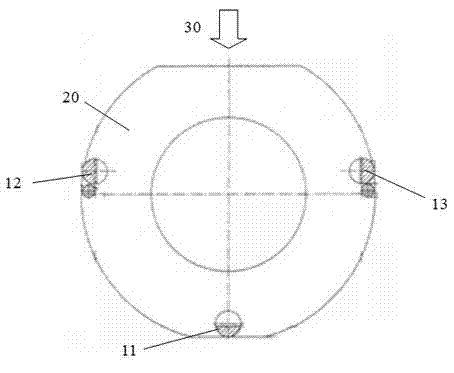

[0020] In a preferred embodiment, two auxiliary struts 40 that are parallel to each other with the three grooved rods 10 of the quartz boat are provided, and these auxiliary struts 40 are also distributed on the outer circumference of the frame 20, and the first auxiliary strut wherein The support bar 40 is located between the first channel bar 11 and the second channel bar 12 , and the second auxiliary support bar 40 is located between the first channel bar 11 and the third channel bar 13 .

[0021] In this embodiment, at least between the second slot bar 12 and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com