Three-rod quartz boat for vertical oxidation furnace tube

A technology of quartz boats and oxidation furnaces, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of device function failure, particles falling to the surface of a silicon wafer below, etc., to prolong the deformation period and improve particle size. condition, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

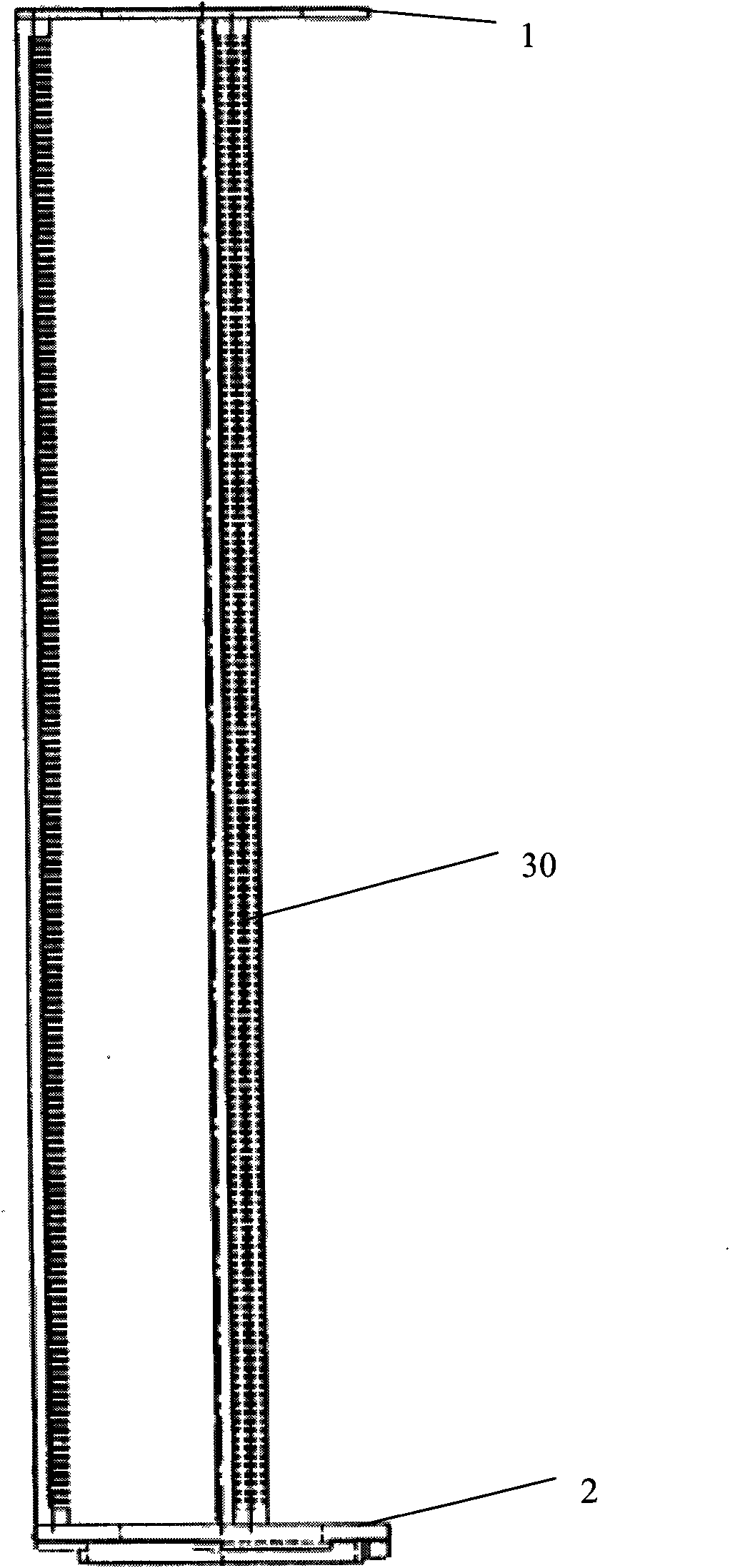

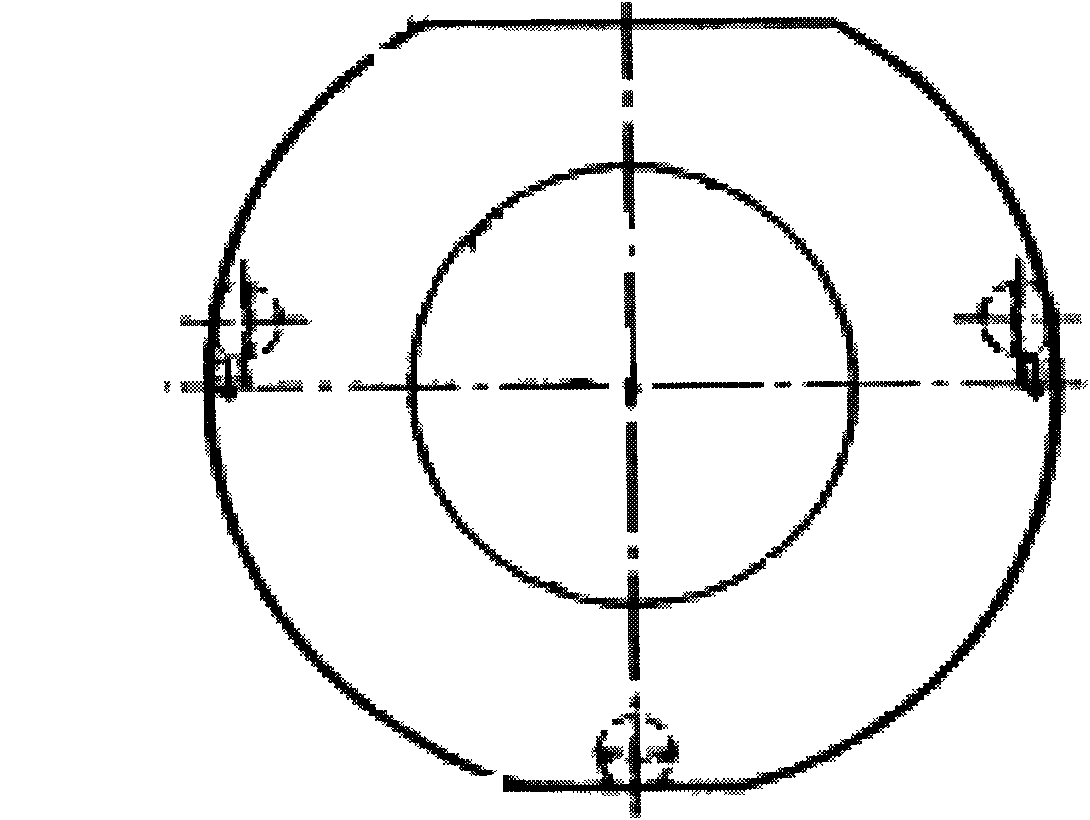

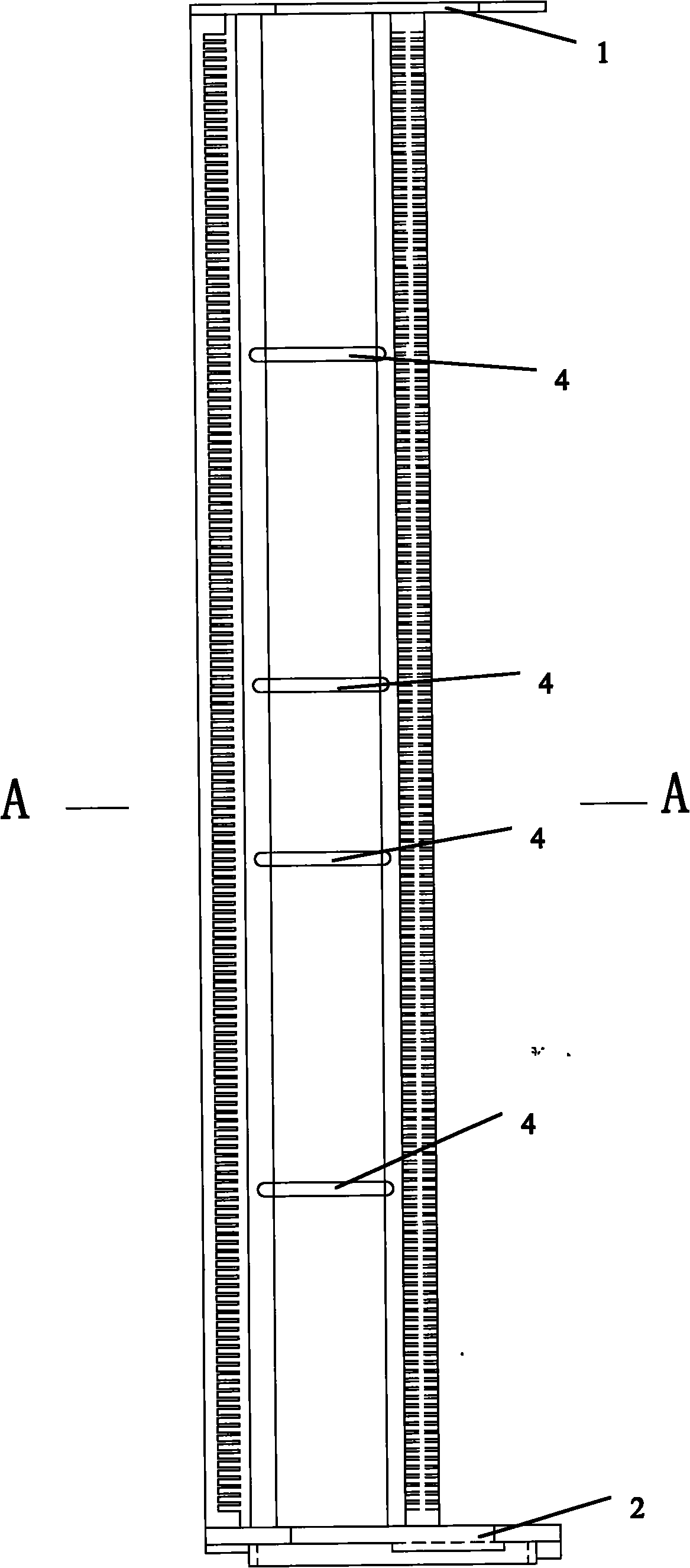

[0030] The present invention is used for the three-column quartz boat of vertical oxidation furnace pipe, comprises upper cover 1, bottom plate 2, three vertical upright columns, and upper cover 1 and bottom plate 2 are rings with the same size, and the top end of vertical upright column connects ring-shaped upper cover 1, and the bottom end Connect the ring base plate 2. The inner side of the column is provided with a plurality of slots for silicon wafers, and the slots for silicon wafers are arranged along the axial direction of the column for supporting the silicon wafers.

[0031] The cross section of the column is circular, wherein the first column A and the second column B are arranged symmetrically with respect to the central column C, and the connecting line between the two columns A and B deviates from the diameter of the upper cover 1 and the bottom plate 2 . The diameter of the central column C is larger than the other two columns A and B.

[0032] The diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com