Method for improving HTO thickness stability

A stable and clean technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the influence of the accumulation thickness of by-products that cannot be targeted, the thickness of the product silicon wafer deviates from the target value, and the bottom Solve problems such as film thickness fluctuations, achieve the effect of improving environmental particle conditions, ensuring thickness stability, and removing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

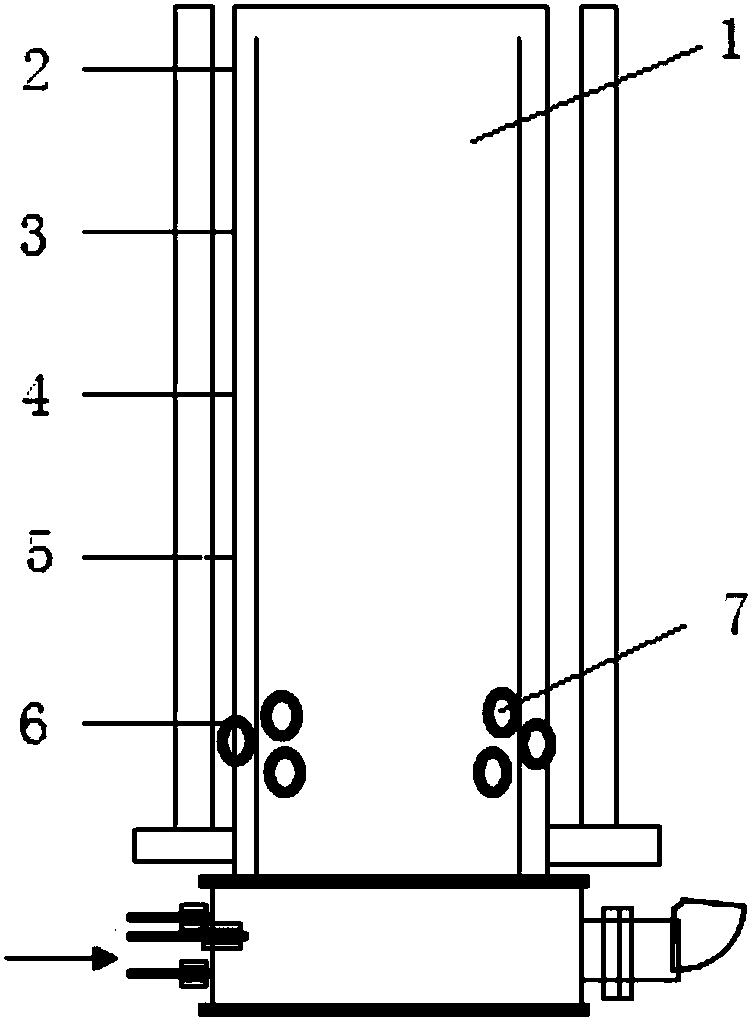

[0014] The method for improving the thickness stability of HTO is to automatically run a new cycle cleaning program to remove the bottom of the process chamber when the cumulative film thickness of the low-pressure furnace tube HTO machine reaches a certain value, for example, the cumulative film thickness reaches 1 μm to 2 μm. By-products (chloride ions), reduce or even avoid the influence of bottom by-products on the film thickness, improve the thickness stability of the film-forming process, and ensure stable product quality.

[0015] If the method for improving the thickness stability of HTO is followed, the by-products (chloride ions) at the bottom of the process chamber can be effectively removed to avoid its influence on the thickness of the film, and finally achieve the purpose of improving the thickness stability of the film formation process.

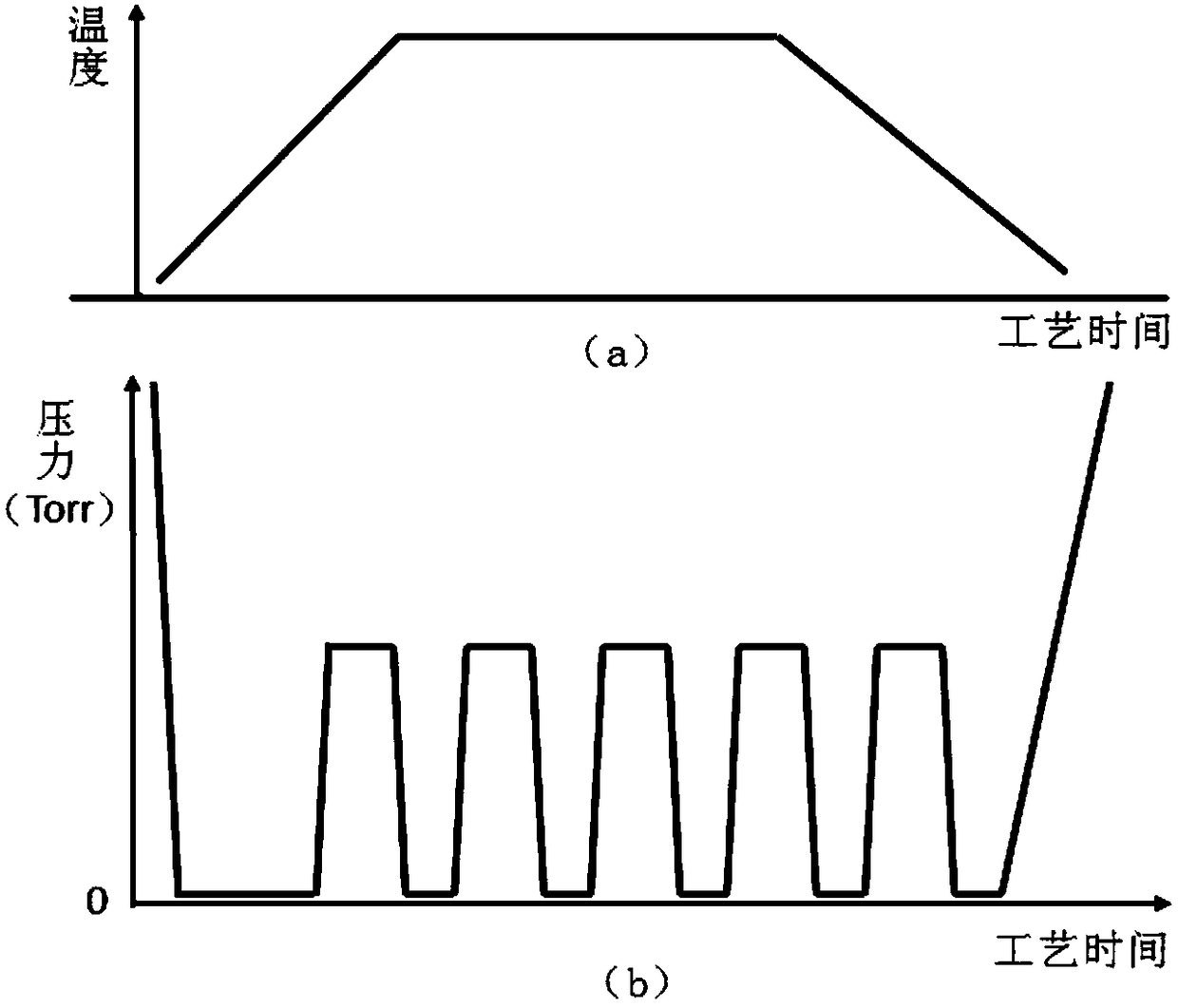

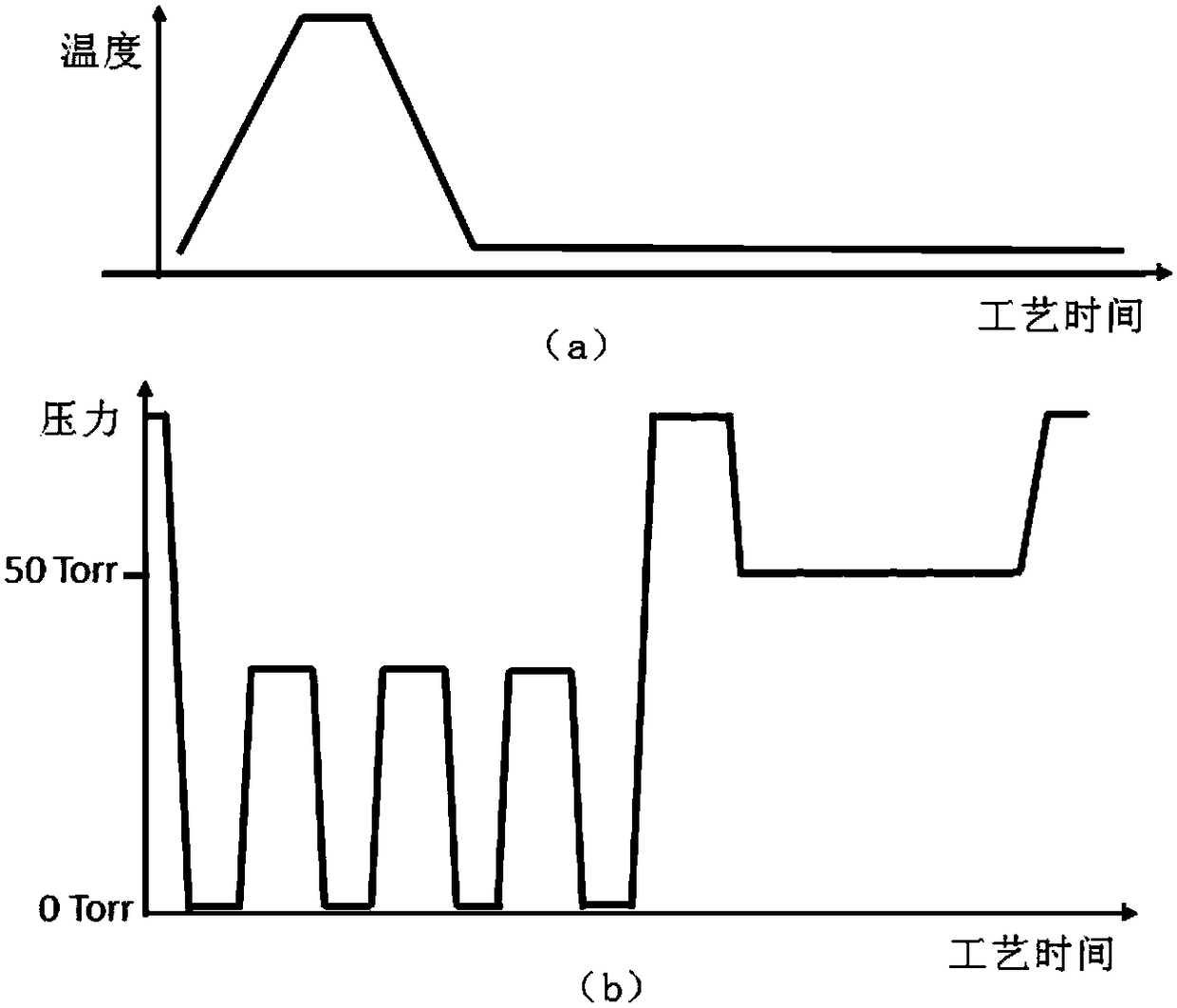

[0016] The key point of the method for improving the thickness stability of HTO is to propose a new cycle cleaning program, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com