A metal round bar bending shaper

A technology for bending and forming round bars, applied in the field of metal round bar bending formers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, the specific embodiments of the present invention will be further described in conjunction with the accompanying drawings to make the technical solutions and beneficial effects of the present invention clearer and clearer.

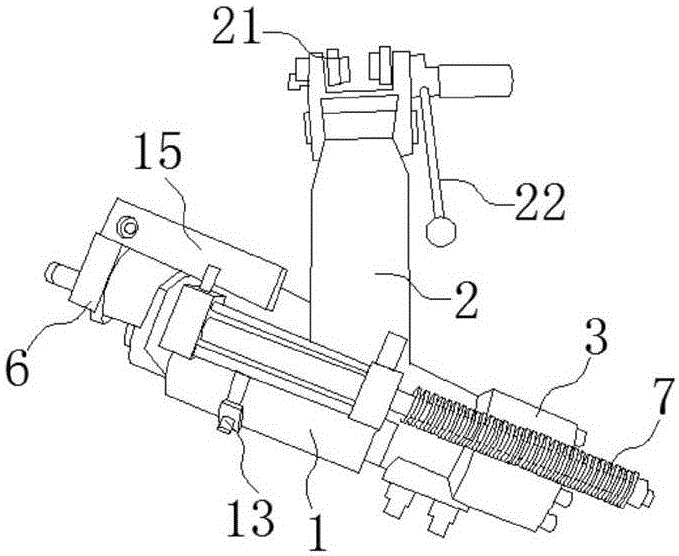

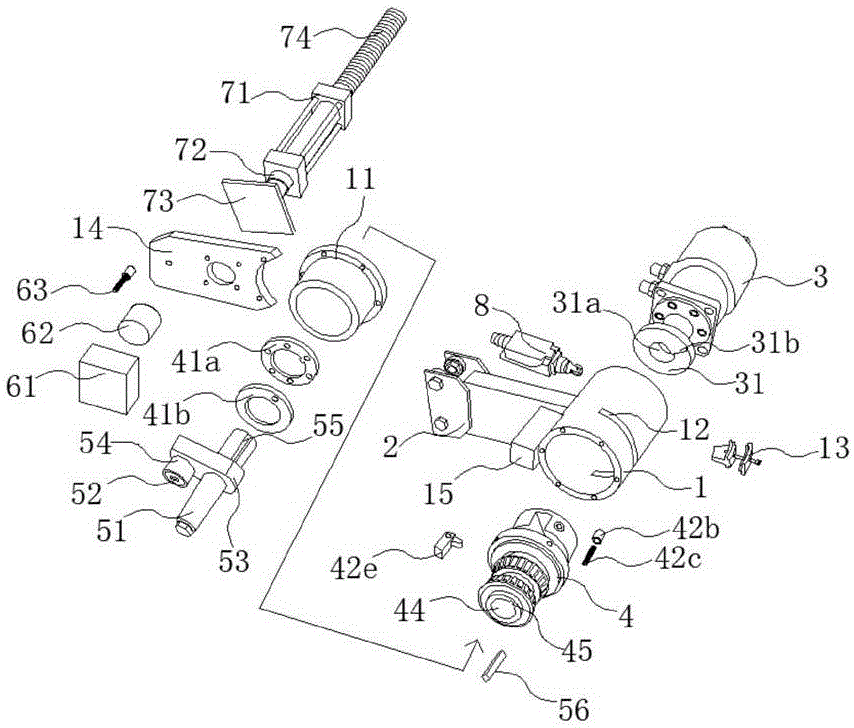

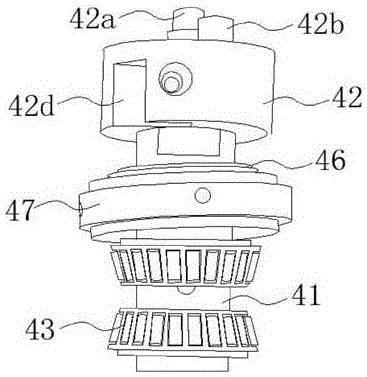

[0021] See attached Figure 1 to 5 The present invention includes a housing 1 and a mounting bracket 2 connected to the housing 1. A hydraulic motor 3 is provided at the rear end of the housing 1, a housing cover 11 is provided at the front end of the housing 1, and a transmission device 4 is provided in the housing 1; a transmission device 4 The rear end of the transmission device 4 is connected with the hydraulic motor 3, and the front end of the transmission device 4 is connected with a bending head 5 for bending the metal round bar; a stroke adjustment groove 12 is provided on the side wall of the housing 1, and the stroke adjustment groove 12 is provided with On the stroke adjustment block 13 that limits the rotation range of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com