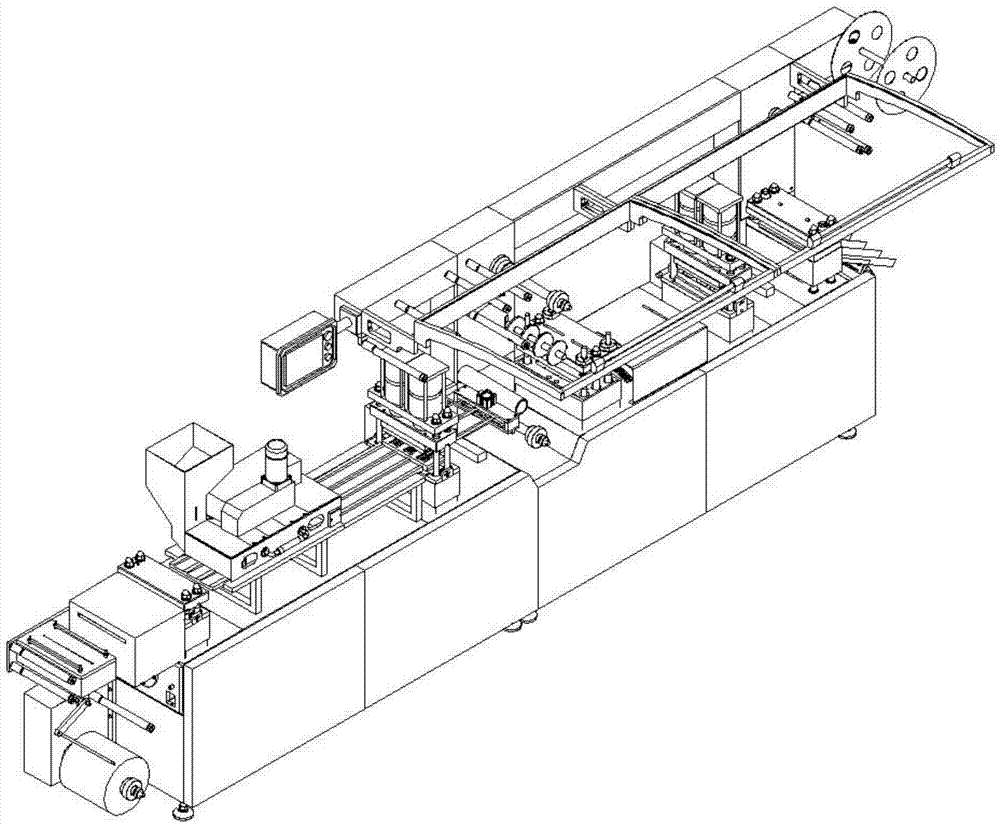

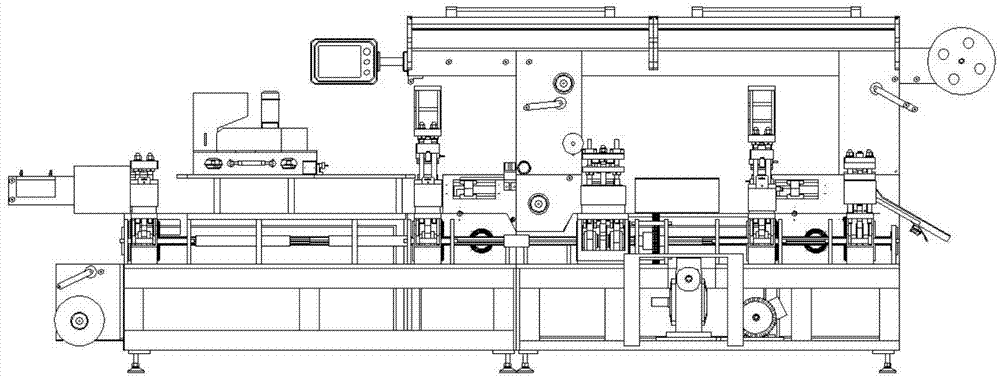

Combined type heat sealing mechanism and roller plate type aluminum plastic aluminum blister packaging machine

A technology of blister packaging machine and aluminum-plastic packaging, which is applied in the direction of transportation and packaging, packaging, transportation packaging, etc., and can solve the problems of insufficient heat sealing of blister plates and aluminum foil, high precision requirements of transmission mechanisms, and burns of surrounding staff, etc. problems, to achieve the effect of reducing the requirements for coordinated actions, preventing burns, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. These exemplary embodiments are provided so that those skilled in the art can clearly understand the present invention and implement the present invention according to the description herein. The drawings and specific examples are not intended to limit the invention, the scope of which is defined by the appended claims.

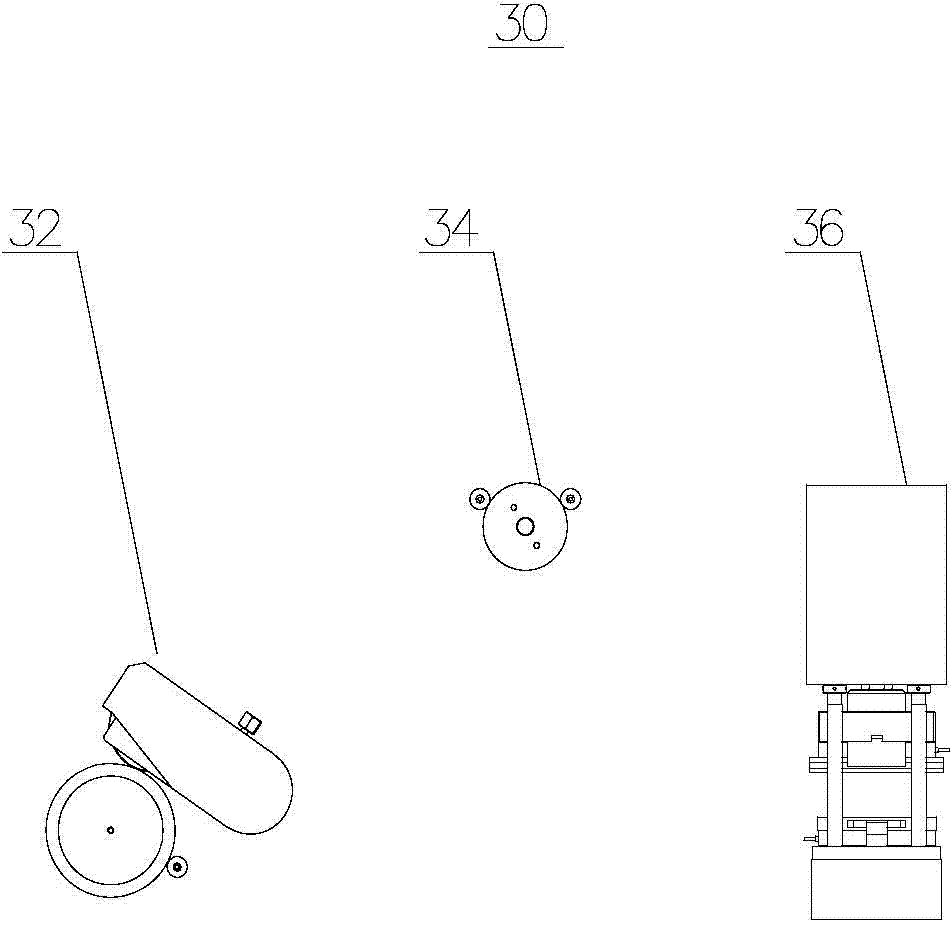

[0032] image 3 It shows a front view of the composite heat-sealing mechanism 30 according to the present invention, omitting the driving mechanism; Figure 4 shown in image 3It is a schematic diagram from the blister plate to the aluminum-plastic-aluminum package during the working process of the composite heat-sealing mechanism 30 shown. The composite heat-sealing mechanism 30 includes: a rolling heat-sealing device 32, which operates continuously, and is used to heat-seal the blister plate 62 from the conveying mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com