Method for adjusting projection light angle of LED lamp

A technology of LED lamp and projected light, which is applied in the direction of light source, refractor, light source fixation, etc., can solve the problems of high cost and low assembly efficiency, and achieve the effect of low cost of use, easy light output angle, and adjustment of light output angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The method for adjusting the projected light angle of the LED lamp according to the present invention comprises the following steps:

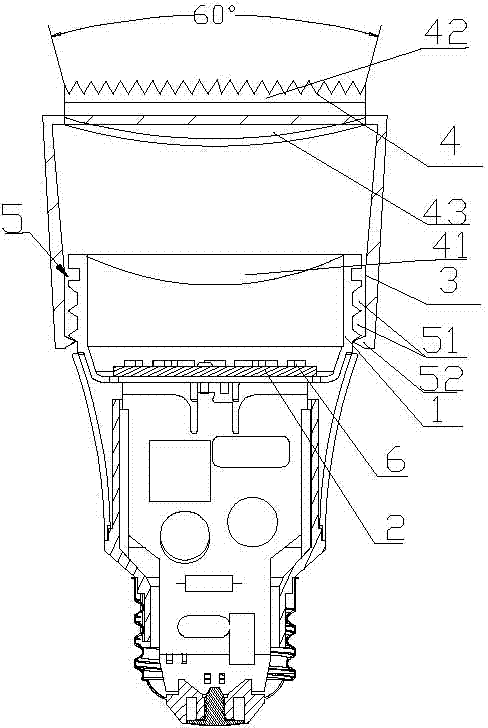

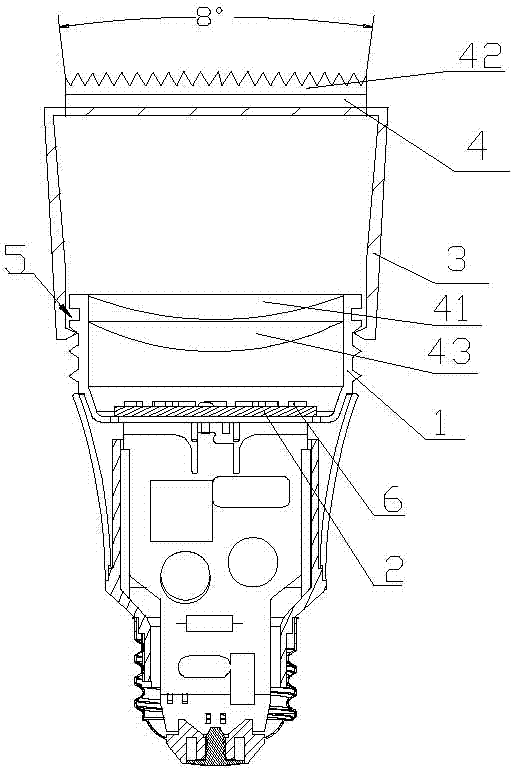

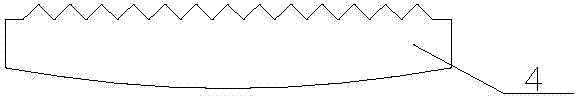

[0036] A lens group 4 is fixed in the light output direction of the LED lamp to achieve the effect of improving the brightness of the light output and lay the foundation for focusing. The lens group 4 can be set in the lamp cup 1 or lampshade 3 or in the lamp cup 1 and lampshade 3 respectively. lens. Then a focusing mechanism 5 is set between the lamp cup 1 and the lampshade 3 of the LED lamp, and the two are connected together through the focusing mechanism 5; lights6.

[0037] The manufactured LED lamp includes a lamp cup 1 with an LED lamp board 2 inside, and the lamp cup 1 is connected with a lampshade 3 through a focusing mechanism 5 . A lens group 4 is provided inside the end of the lampshade 3 for projecting the light emitted by the LED lamp on the LED lamp board 2 . The relative position of the lampshade 3 and the lamp cup 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com