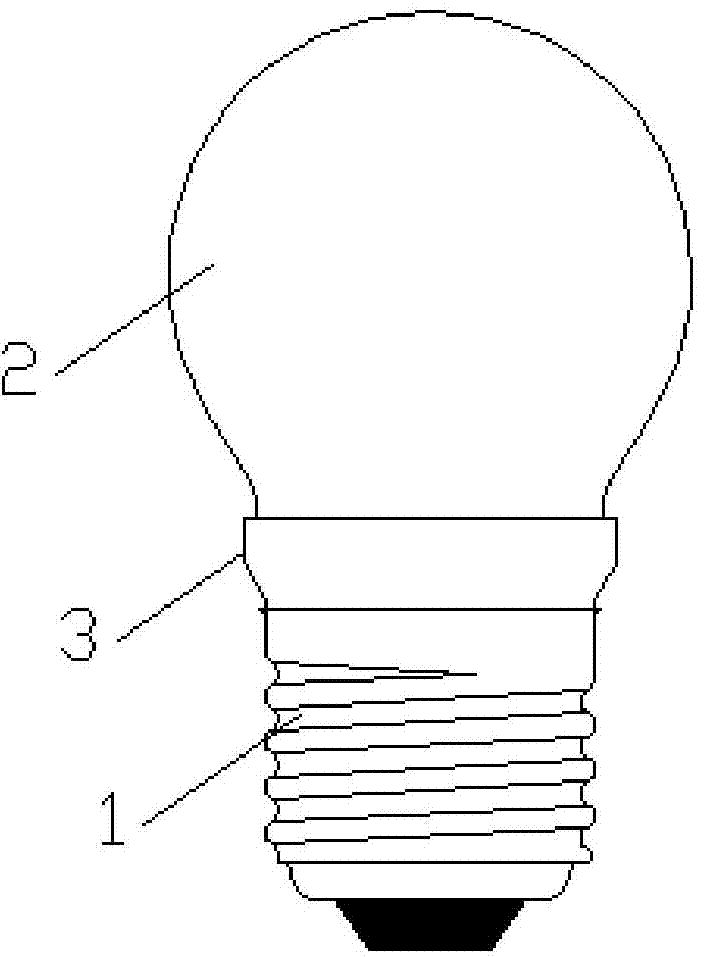

Connection method for glass bulb and lamp cap

A connection method and a technology of lamp holders, which are applied to components of lighting devices, lighting devices, light sources, etc., can solve the problems of high production cost and long lamp dimensions, and achieve low cost, well-proportioned and reasonable dimensions, and simple production methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

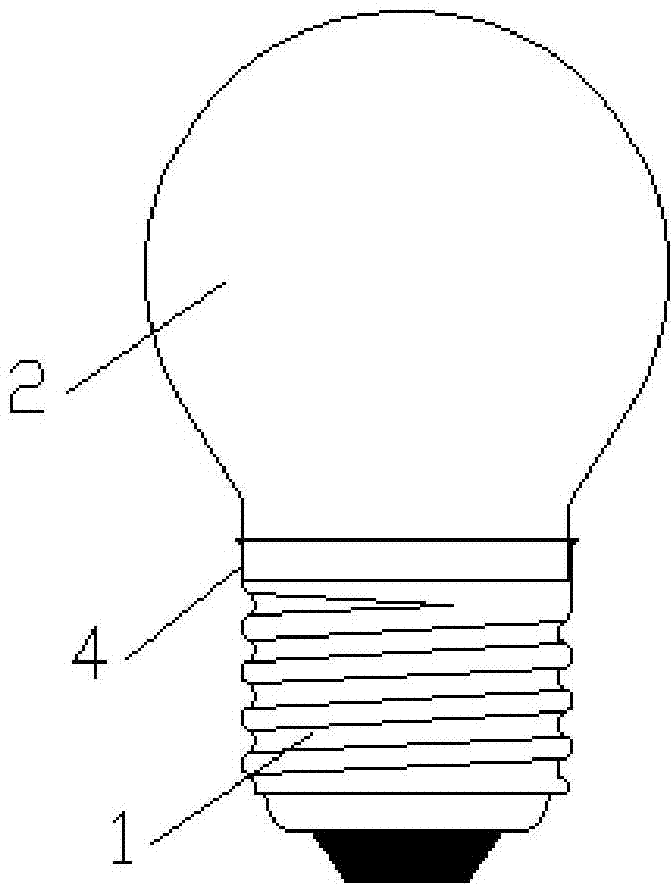

[0014] Such as figure 2 and image 3 As shown, the glass bulb 2 and the lamp cap 1 are connected by a metal ring 4, and the manufacturing method is as follows: making a metal ring, the outer diameter of the metal ring matches the inner diameter of the mouth of the lamp cap, and the inner diameter matches the inner diameter of the mouth of the glass bulb. After the metal ring is connected to the glass bulb through high temperature treatment, the inner surface of the metal ring is coated with cement, inserted into the mouth of the lamp cap to combine the edge of the mouth of the lamp cap with the glass bulb, and then fixed by dotting.

[0015] Rationale for this approach:

[0016] The metal ring is made of aluminum alloy, and its Mpa value is about 150. The lamp cap is made of H62 brass with nickel surface treatment, and its Mpa value is about 320. Through the general bubble test of the aluminum lamp cap, the dotting force of 100N is pressed on the aluminum lamp cap point, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com