Method for determining specific fatigue strength rated value under multi-axial loading condition

A multi-axial load and fatigue strength technology, applied in the field of fatigue strength, can solve the problem of less research on DFR theory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is illustrated in conjunction with the accompanying drawings.

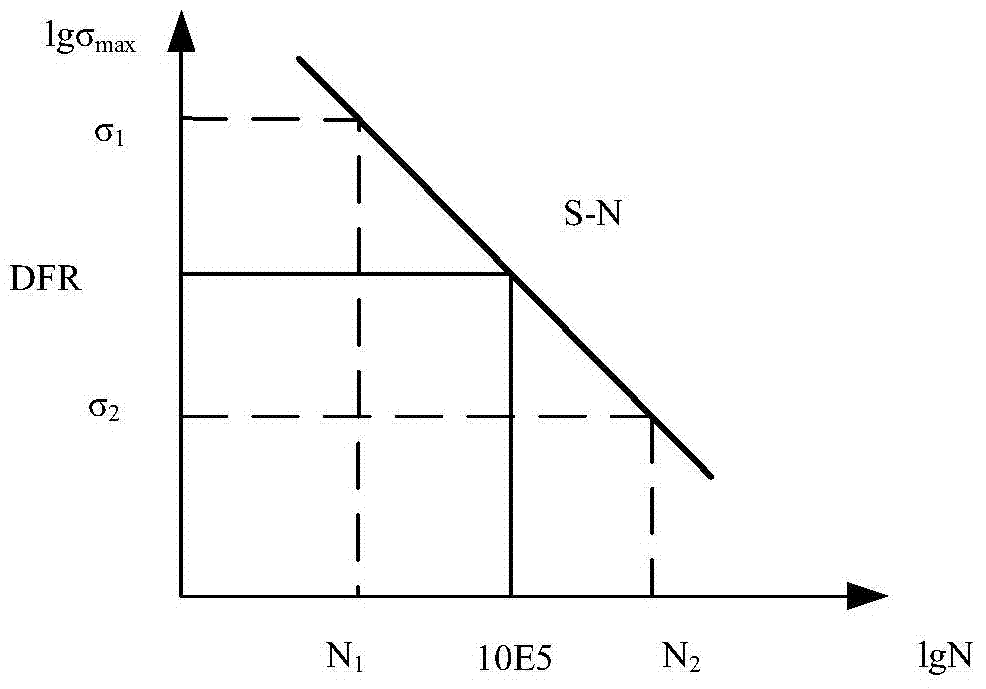

[0027] The present invention further illustrates the present invention through the fatigue test, the test is divided into two parts, one part is a uniaxial DFR test, the stress ratio is 0.06, and the test is for calculating the DFR value. According to the method of calculating the DFR value by the two-point method, two stress levels are selected, and a group of experiments are done under each stress level, and the life of the specimen is within a certain range. The other part is the multiaxial proportional and non-proportional test, which is to calculate the DFR value under multiaxial loading conditions.

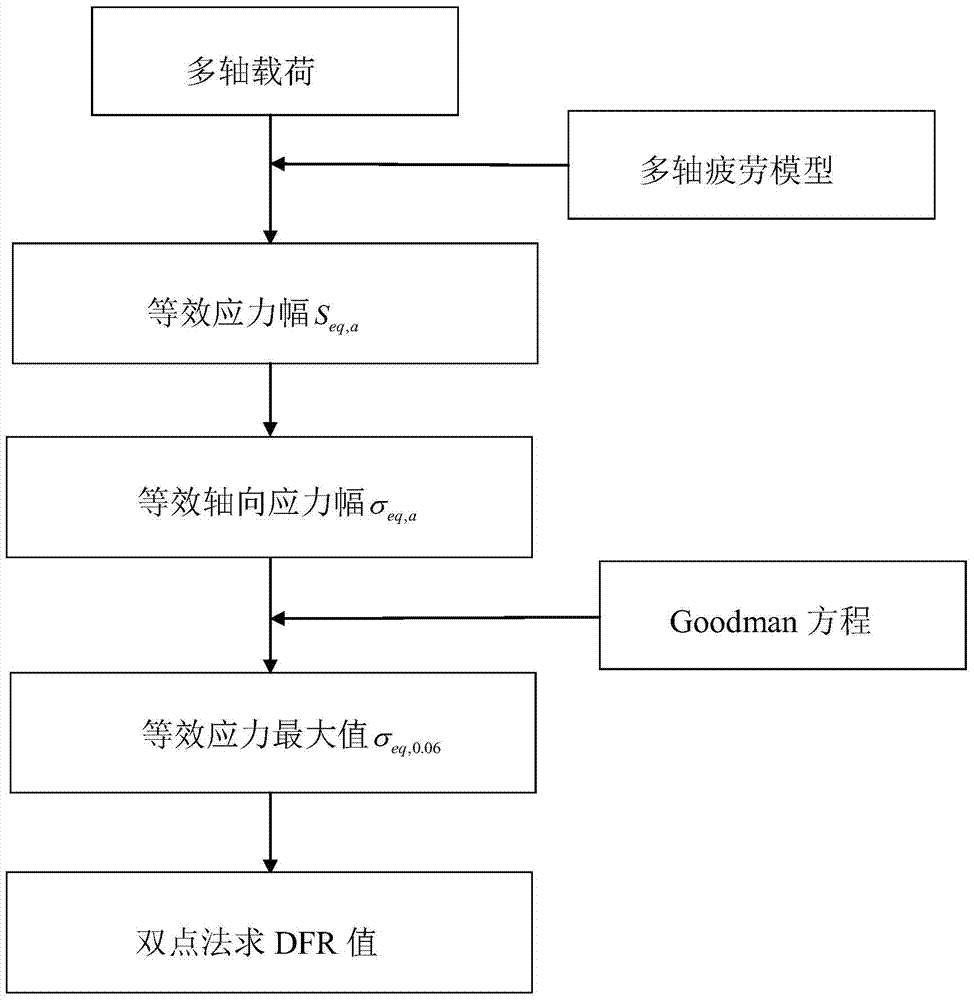

[0028] A method for determining the fatigue strength rating of details under multiaxial loading conditions, the specific calculation method is as follows:

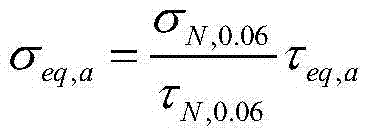

[0029] Step 1): Using the existing high-cycle multiaxial fatigue model to convert the multiaxial load into the equivalent stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com