Dye laser based on novel SMOF

A technology of microstructure optical fiber and dye laser, which is applied in the field of dye laser, can solve the problems of microchannel occupation and unfavorable microfluidic control, etc., and achieve the effect of firm structure, firm and stable structure, mature and simple manufacturing process

Active Publication Date: 2014-07-23

NANKAI UNIV

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The use of axial pumping requires a precise coupling method, which makes one e

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

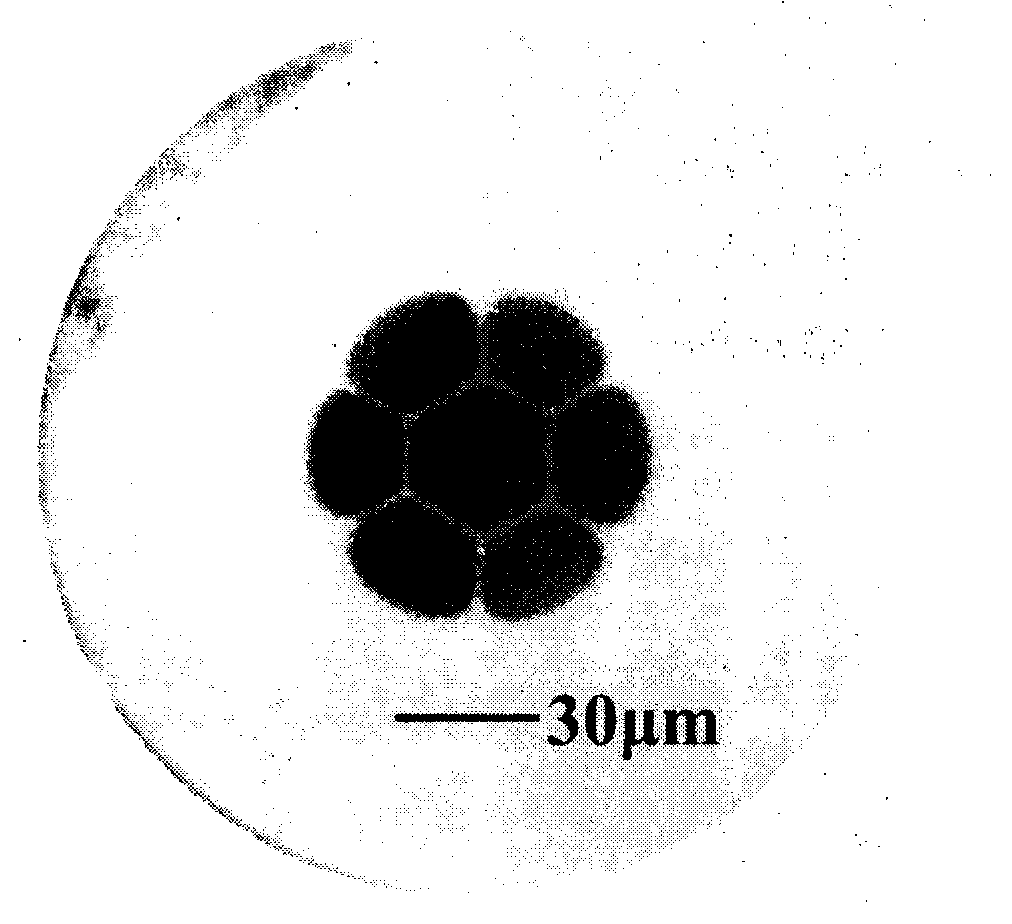

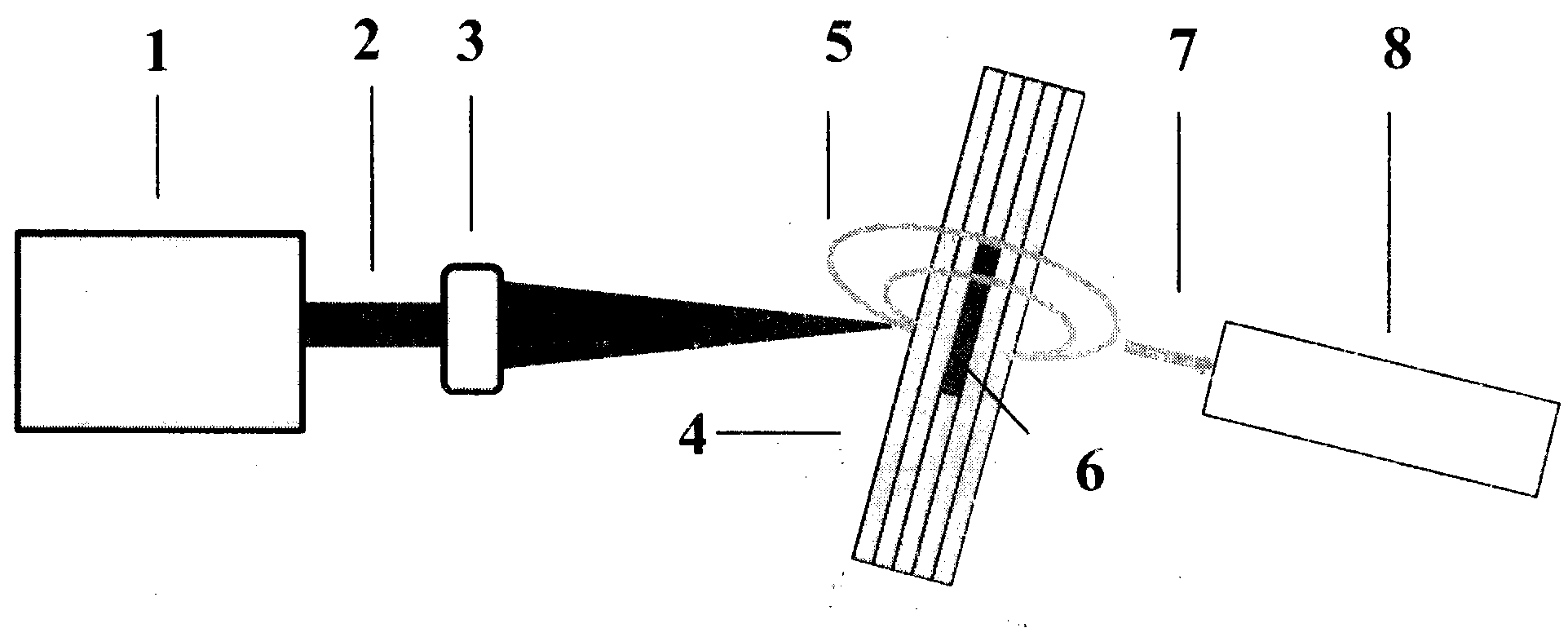

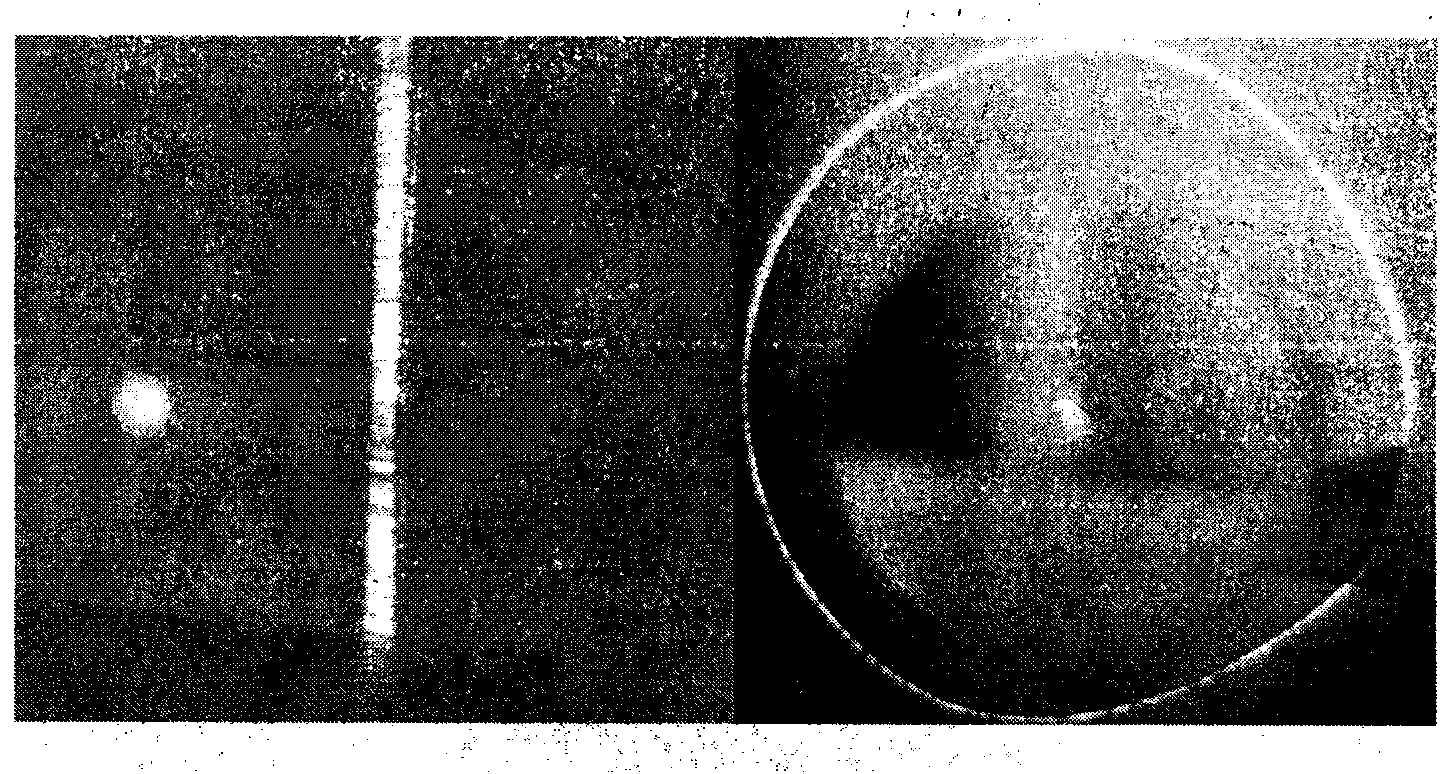

A laser of a novel SMOF filled with a liquid core has the strong radiation and laser emitted in the radial direction of the optical fiber. A micro-flow channel is composed of holes which are approximately cylindrical and formed in the center of the SMOF. A center hole of the hollow SMOF is selectively filled with a section of Rhodamine 6-G dye liquid, and a nanosecond pulse laser of 532 nm pumps in the transverse direction of the part filled with the optical fiber. Based on the novel hollow SMOF, an optical fiber side face pumping system is combined, the micro-flow channel is selectively filled by the utilization of the SMOF, and the independent SMOF is used, so that radiation of gain media is achieved, and the emitted laser has high stability and tenability. The dye laser based on the SMOF is firm in structure and small in size so as to be applied to integrated equipment conveniently. The dye laser is combined with an immunofluorescence method of a fixed antibody in the hollow optical fiber holes so as to be applied to an optical fluid microsystem on biomedical detection and chemical analysis.

Description

Technical field [0001] The invention relates to a dye laser of a microstructure fiber, which is based on a new type of hollow microstructure fiber, combined with a fiber side pumping system. The device utilizes the selective filling of microchannels of the microstructure fiber, and uses an independent microstructure fiber to realize the gain medium. Lasing, laser emission is tunable, and has the characteristics of high intensity and radial radiation. Background technique [0002] The luminescence mechanism of microcavity lasers is that multiple reflections in the microcavity make standing waves form at specific frequencies in the optical cavity. Due to the strong light confinement in the microcavity, the interaction between light and matter in the microcavity is enhanced, and the resonant cavity mode becomes more stable. sharp. Microcavity dye lasers can be made very small and integrated on a chip to make a small portable device. At the same time, due to the different emiss...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01S3/20H01S3/10

Inventor 周文远李志莉刘艳格晏敏田建国

Owner NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com