Hydraulic lift truck for carrying armoring movable-type switch cabinet functional vehicles

A hydraulic lifting and moving technology, which is applied to switch devices, lifting devices, electrical components, etc., can solve the problems of backward movement of hydraulic lifting vehicles, falling of functional vehicles, and failure of automatic self-locking of functional vehicles. The effect of convenient lifting and landing, up and down adjustment is convenient and free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Specific embodiments of the present invention are provided below in conjunction with the accompanying drawings.

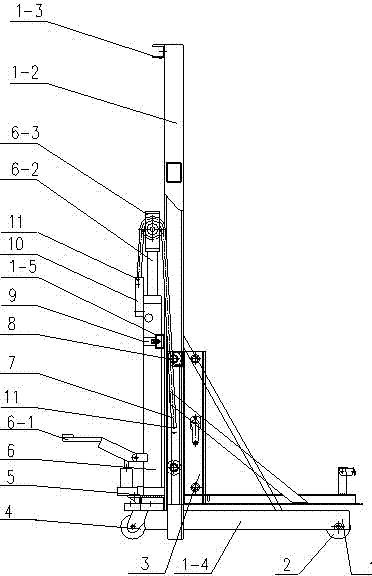

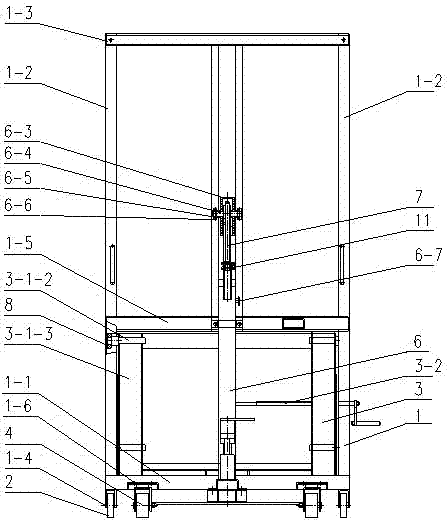

[0055] Such as figure 1 and figure 2 As shown, the present invention comprises a vehicle frame 1, a lifting mechanism 3 and a lifting cylinder 6, and the vehicle frame 1 is at least composed of a vehicle frame lower beam 1-1, two left and right vehicle frame columns 1-2, and a vehicle frame upper beam 1-3. , 2 left and right vehicle frame side beams 1-4 and vehicle frame middle beam 1-5 are welded together, install 2 guiding front wheels 2 on the vehicle frame side beams 1-4, and the vehicle frame lower beam 1-1 Weld the wheel mounting plate 1-6 on the top, and install 2 rear wheels 4 under the wheel mounting plate 1-6. The rear wheel 4 is a universal wheel, and the front wheel 2 and the rear wheel 4 can allow the lift car to move freely. Lifting mechanism 3 is installed on the top;

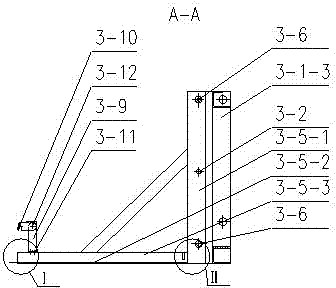

[0056] Such as image 3 , Figure 4 and Figure 5As shown, the lift...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com