LED driving hot swap control circuit

A technology of LED drive and LED driver, which is applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc. It can solve the problems of high output current, easy burning of LED lamp beads, and easy damage of LED lamp beads, so as to prolong life and simplify implementation Effective, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

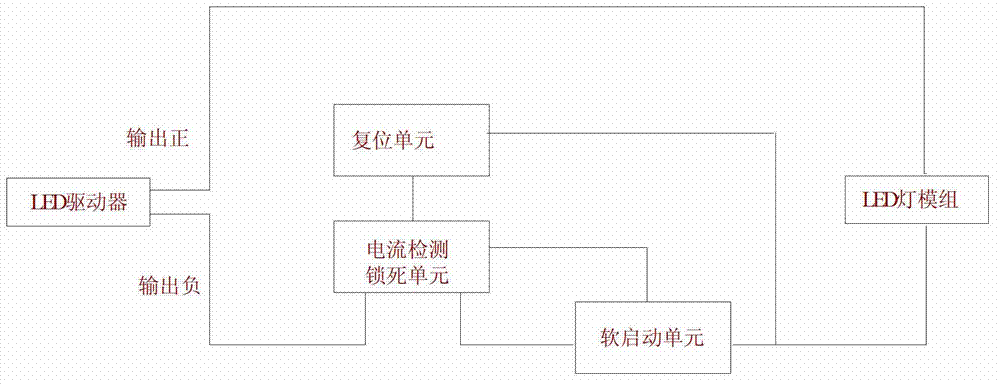

[0016] Such as figure 1 As shown, a LED driver hot swap control circuit, the control circuit is connected between the LED driver and the LED lamp module, the control circuit includes a current detection locking unit, a soft start unit and a reset unit, the described The current detection locking unit is respectively connected with the LED driver, the soft start unit and the reset unit, and the soft start unit is respectively connected with the reset unit and the LED lamp module;

[0017] When the current signal detected by the current detection locking unit exceeds the set threshold, the soft start unit will be turned off to disconnect the LED driver from the LED lamp module, and the reset unit will reset the current detection locking unit after disconnection. The current detection locking unit turns on the soft start unit, so that the LED driver and the LED lamp module are connected.

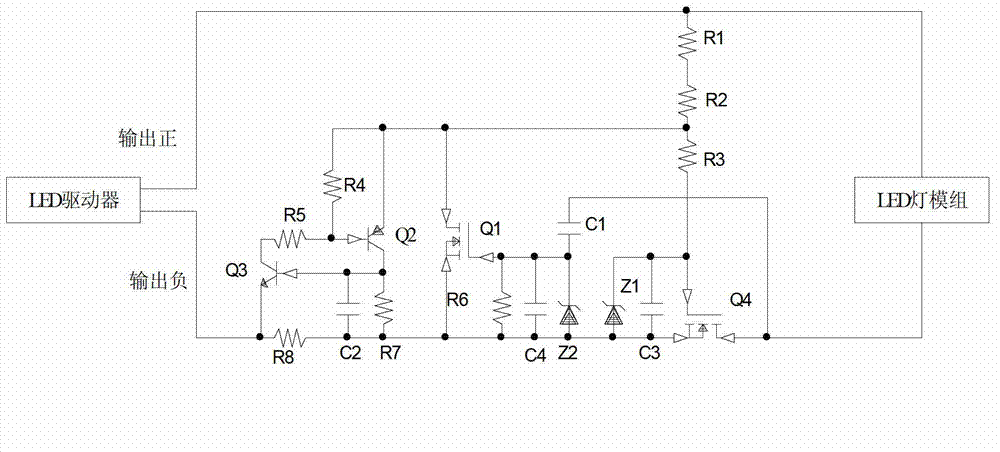

[0018] Such as figure 2 As shown, the current detection locking unit includes a transist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com