Gas-liquid contact extraction method and device

A technology of gas-liquid contact and extraction method, applied in sampling device, measuring device, sampling and other directions, can solve the problem of large distribution coefficient, and achieve the effect of improving the contact rate and improving the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

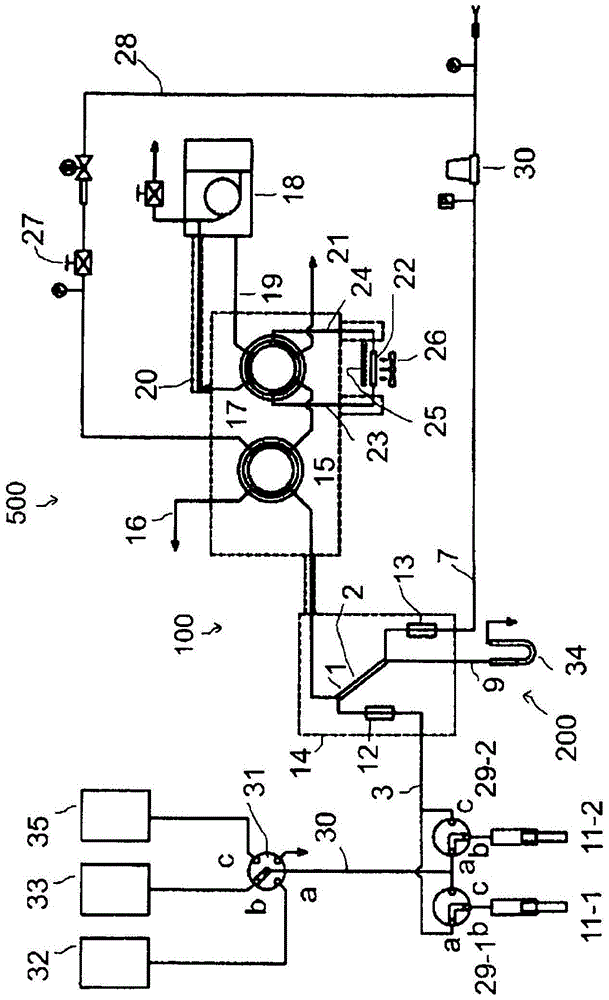

[0127] Passed the previous P&T method and used figure 1 The gas-liquid contact extraction method of the present invention, which includes the system of the gas-liquid contact extraction device of the present invention and the automatic liquid sample supply device, analyzes the sample water containing 2-MIB and Geosimin. Shows an experimental example of the comparison of the amount of material migration to the gas phase between 2-MIB and Geosimin.

[0128] [Table 2]

[0129]

[0130]

[0131] Table 2 is related to the conventional P&T method and the gas-liquid contact extraction method of the present invention. It shows the theoretical mass transfer amount and the respective extraction efficiency of 2-MIB and Geosimin moving from the liquid phase to the gas phase at a concentration of 5 ppt (5 pg / mL). In the conventional P&T method, the sample water volume was 20 ml. In the method of the present invention, the water was passed at a flow rate of 2 ml / min for 20 minutes, so the total ...

Embodiment 2

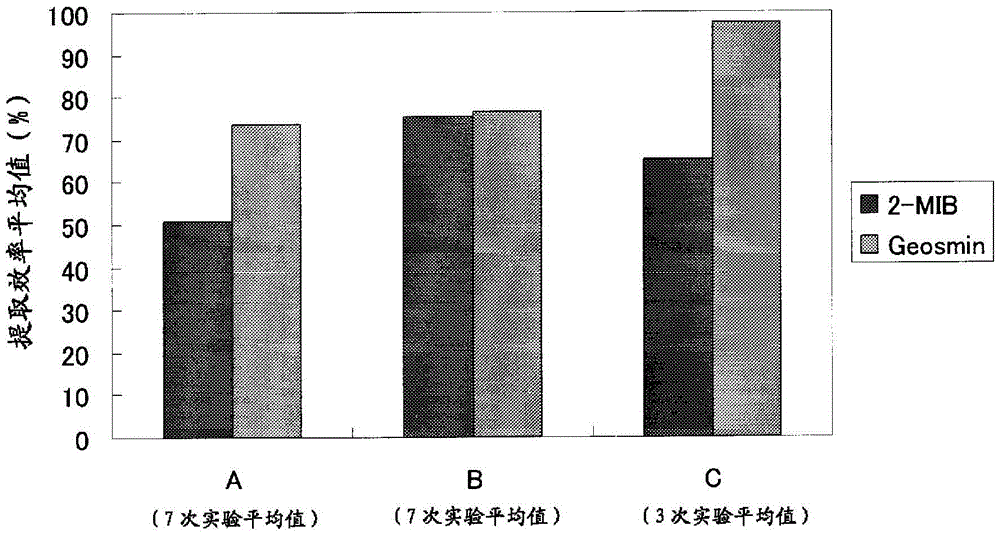

[0162] For the gas-liquid contact extraction method of the present invention using the automatic liquid sample supply device of the present invention, the purge gas flow rate and the sample water flow rate are changed to compare the extraction efficiency of 2-MIB and Geosimin. The extraction efficiency conditions of 2-MIB and Geosimin based on purge gas flow and sample water flow are:

[0163] A: Sample water flow: 4ml / min, purge gas flow: 160ml / min, extraction time: 10 minutes

[0164] B: Sample water flow rate: 2ml / min, purge gas flow rate: 80ml / min, extraction time: 20 minutes

[0165] C: Sample water flow rate: 1ml / min, purge gas flow rate: 40ml / min, extraction time: 40 minutes,

[0166] The extraction temperature was 60°C. The result is expressed in image 3 . It is found that the condition for obtaining high extraction efficiency for both components is B in the figure.

[0167]

[0168] (1) Sample water extraction conditions

[0169] 1) Extraction temperature of sample water: 60...

Embodiment 3

[0194] Based on figure 1 The 2-MIB and Geosimin analysis reproducibility of the system including the gas-liquid contact extraction device and the automatic liquid sample supply device of the present invention were tested. 2-MIB and Geosimin have been known as musty-causing substances in tap water. However, according to the Tap Water Law in April 2005, as a water quality standard item, a low standard value of 0.01μg / L (10ppt) was set. As the lower limit of quantification, an extremely low value of 1 / 10 of 0.001μg / L (1ppt) is required. The olfactory threshold is described in the "Guidelines for Olfactory Measurements" issued by the Ministry of the Environment.

[0195] A repeated reproducibility test with the concentration of 1 ppt of each of 2-MIB and Geosimin was performed. The result is expressed in Figure 4 , Figure 5 , Image 6 . In addition, the CV (%) of the peak area values of 2-MIB and Geosimin in the three measurements was calculated. The good results shown in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com