An intelligent sprinkler irrigation machine self-propelled nozzle vehicle and its use method

A sprinkler vehicle and self-propelled technology, applied in botany equipment and methods, applications, horticulture, etc., can solve the problems affecting the quality and efficiency of sprinkler irrigation, time-consuming and laborious, and low degree of automation, so as to save time and cost of sprinkler irrigation and improve sprinkler irrigation. Efficiency, effect of compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

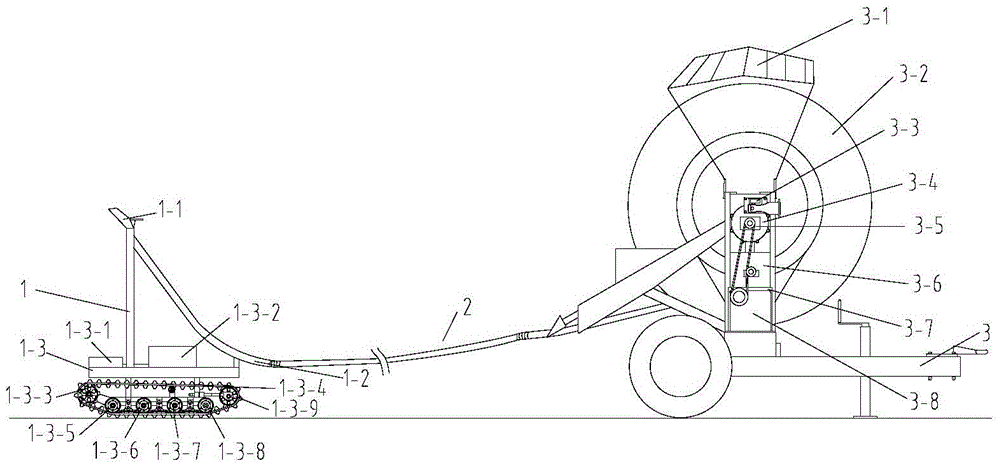

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

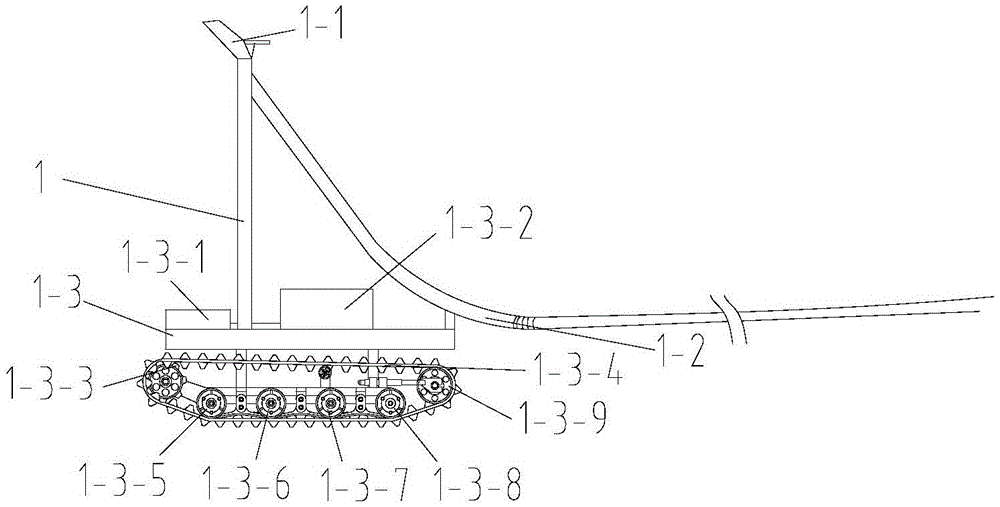

[0022] The intelligent sprinkler irrigation machine self-propelled nozzle vehicle of the present invention is mainly composed of a nozzle 1-1, an auxiliary PE pipe 1-2 and a vehicle body 1-3, and one end of the auxiliary PE pipe 1-2 is connected to the nozzle 1-1, The other end is connected with the main PE pipe 2.

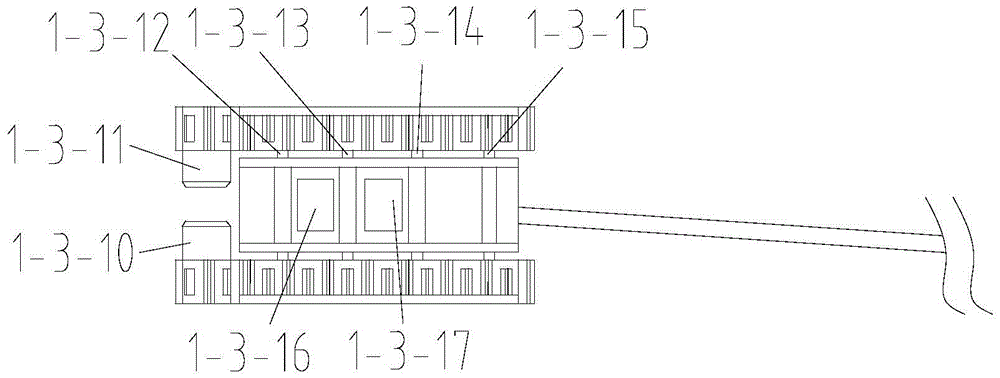

[0023] The nozzle cart includes a nozzle 1-1, a secondary PE pipe 1-2, and a vehicle body 1-3. The nozzle 1-1 and the secondary PE pipe 1-2 are arranged on the nozzle vehicle 1-3. The vehicle body 1 -3 includes detection device 1-3-1, battery one 1-3-2, driving wheel 1-3-3, track 1-3-4, track wheel one 1-3-5, track wheel two 1-3- 6. Track wheel three 1-3-7, track wheel four 1-3-8, driven wheel 1-3-9, drive motor one 1-3-10, drive motor two 1-3-11, hydraulic rod one 1 -3-12,, hydraulic rod two 1-3-13, hydraulic rod three 1-3-14 and hydraulic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com