Mulching film and preparation method thereof

A technology of mulch film and black mulch film, which is applied in the agricultural field, can solve the problems of inability to have both warming, moisturizing and weeding effects, slow land warming, poor light transmittance, etc., and achieves the effect of promoting healthy growth, avoiding frostbite and good weed control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

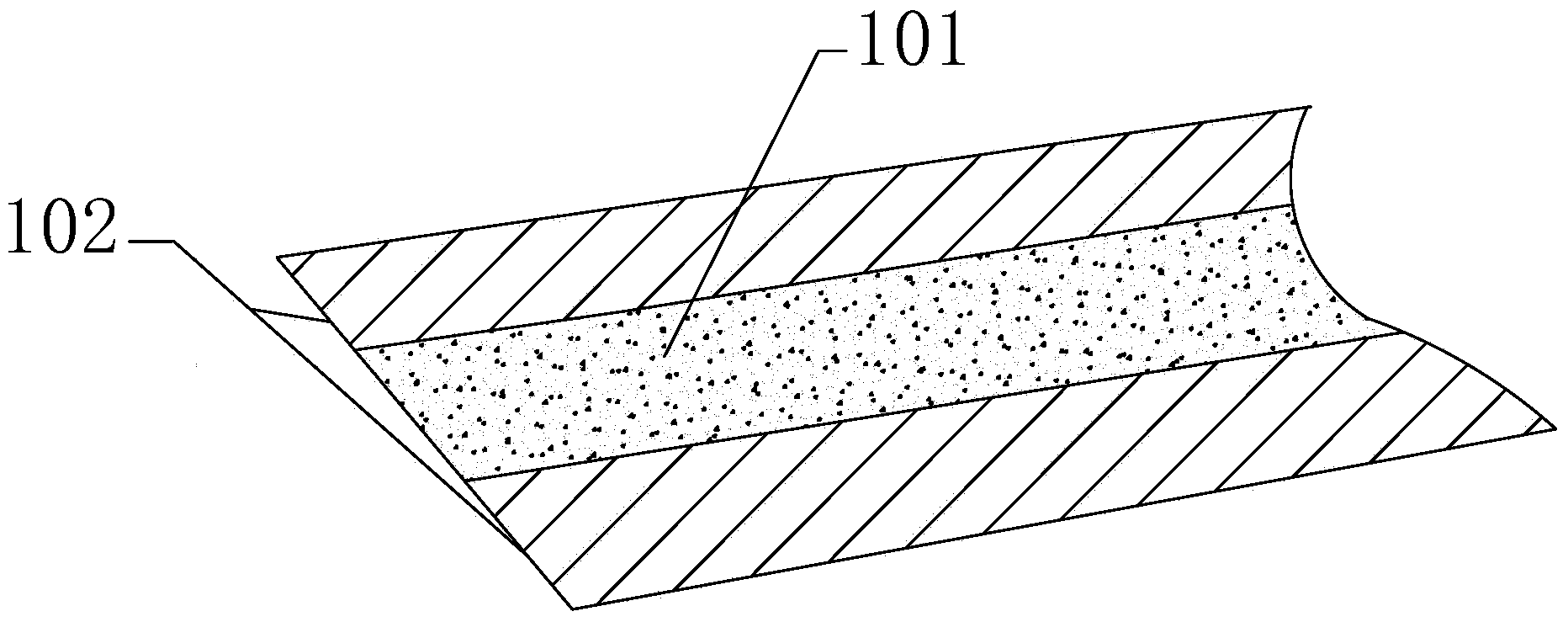

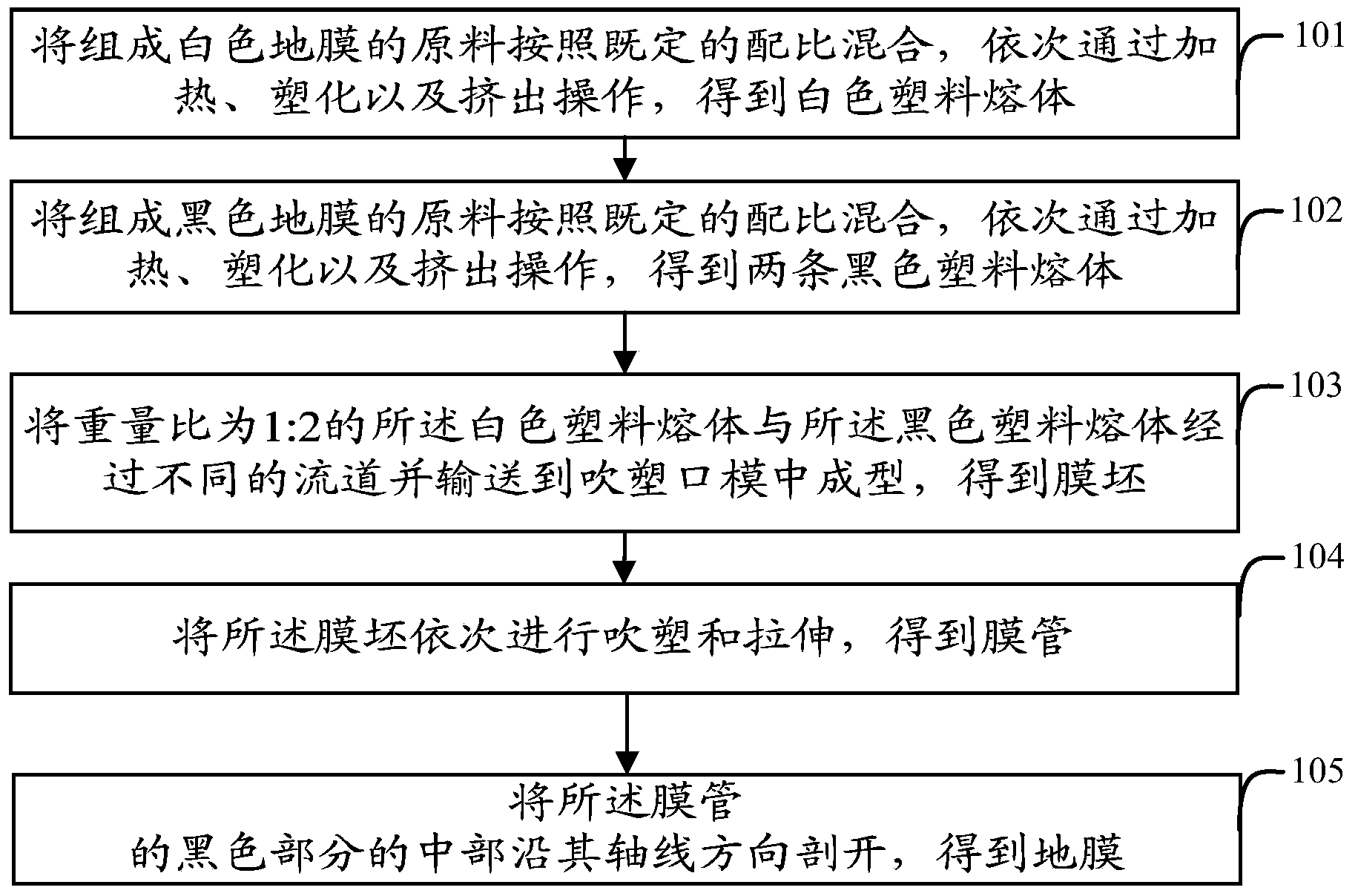

[0031] The mulching film of this embodiment comprises two black mulching films 102 and a white mulching film 101; the white mulching film 101 is arranged between the two black mulching films 102, and is connected with the two black mulching films 102; wherein, in the In the black mulching film 102, according to parts by weight, its raw material components include: 40 parts of degradable masterbatches, 25 parts of linear low-density polyethylene, and 25 parts of carbon black masterbatches; Counting, its raw material components include: 40 parts of degradable masterbatch, 54 parts of linear low density polyethylene.

Embodiment 2

[0033] The mulching film of this embodiment comprises two black mulching films 102 and a white mulching film 101; the white mulching film 101 is arranged between the two black mulching films 102, and is connected with the two black mulching films 102; wherein, in the In the black mulching film 102, according to parts by weight, its raw material components include: 44 parts of degradable masterbatches, 28 parts of linear low-density polyethylene, and 28 parts of carbon black masterbatches; Counting, its raw material components include: 44 parts of degradable masterbatch, 56 parts of linear low density polyethylene.

Embodiment 3

[0035] The mulching film of this embodiment comprises two black mulching films 102 and a white mulching film 101; the white mulching film 101 is arranged between the two black mulching films 102, and is connected with the two black mulching films 102; wherein, in the In the black mulch 102, according to parts by weight, its raw material components include: 46 parts of degradable masterbatches, 30 parts of linear low-density polyethylene, and 30 parts of carbon black masterbatches; in the white mulch 101, according to parts by weight Counting, its raw material components include: 46 parts of degradable masterbatch, 60 parts of linear low density polyethylene.

[0036] In all the above-mentioned embodiments, in order to make the mulch film have a better effect of warming and moisturizing; and to ensure its quality, its multi-functionality (including the performance of easy degradation) is more excellent. Preferably, in the degradable masterbatch; its raw material composition inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com