Water-soluble granule formulation containing paraquat dichloride and preparation method of water-soluble granule formulation

A technology of paraquat dichloride and water-soluble granules, applied in the field of pesticides, can solve the problems of incomplete safety, unsatisfactory overall effect, restrictions, etc., to prevent accidental or intentional ingestion, safe and clean The effects of streamlining production and avoiding exposure to hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

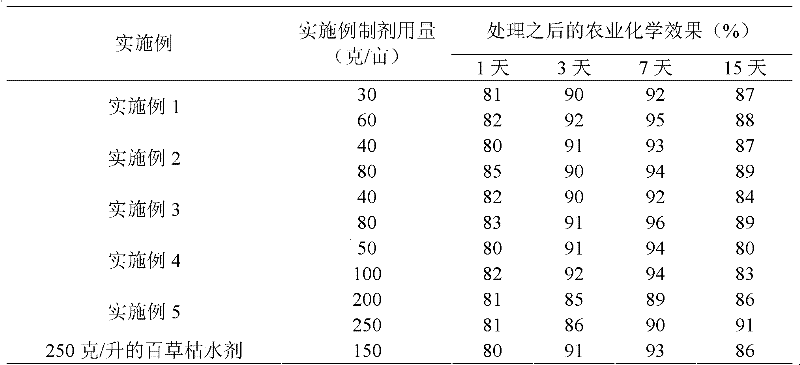

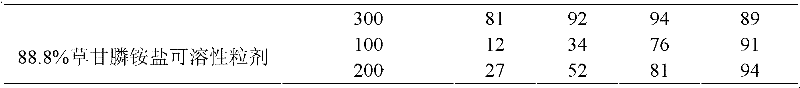

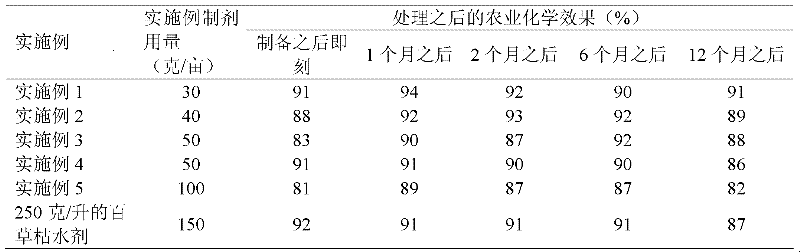

Examples

Embodiment 1

[0029] 75% paraquat dichloride, 5% sodium naphthalenesulfonate formaldehyde condensate, 2% ethylene oxide propylene oxide copolymer (molecular weight 1500-2000, the same below), equivalent to 0.18% of the mass of paraquat dichloride Triazolopyrimidinone, 0.03% ammonium benzide sodium, 0.05% brilliant blue (acid blue 9#), 0.1% pyridine, and the rest is supplemented to 100% with mixed salt of ammonium sulfate and sodium sulfate (mass ratio 1:1) . Then, mix the mixture with 15% water based on the weight of the mixture at room temperature to form a slurry, use the boiling granulation method: mix with hot air, heat up to ≥45°C, keep warm at 45-50°C, spray the mother liquor to granulate, Spray 1000~1200ml / 60~75 seconds each time, stop for 10 seconds, spray 8~10 times in total, compressed air pressure: 6kg / cm 2 , Vacuum exhaust control: inlet: 20 ~ 30mmH 2 O outlet: 350~400mmH 2 O, cool down to room temperature, and form the slurry into particles with a particle size of 0.8-1.2 mm...

Embodiment 2

[0031] 60% paraquat dichloride, 5% sodium octyl naphthalene sulfonate, 2% ethylene oxide propylene oxide copolymer, triazole pyrimidinone equivalent to 0.18% of paraquat dichloride mass, 0.03% saccharin benzyl Ammonium amide, 0.05% brilliant blue (acid blue 9#), 0.1% n-butanol, and the rest was supplemented to 100% with a mixed salt of ammonium sulfate and sodium sulfate (mass ratio 1:1). Then, mix the mixture with 20% water based on the weight of the mixture at room temperature to form a slurry, use the boiling granulation method: hot air mixing, heat up to ≥45°C, keep warm at 45-50°C, spray the mother liquor to granulate, Spray 1000~1200ml / 60~75 seconds each time, stop for 10 seconds, spray 8~10 times in total, compressed air pressure: 6kg / cm 2 , Vacuum exhaust control: inlet: 20 ~ 30mmH 2 O outlet: 350~400mmH 2 O, cool down to room temperature, and form the slurry into particles with a particle size of 0.8-1.2 mm. Particles with a particle size of 0.8 to 1.2 mm are forme...

Embodiment 3

[0033]60% paraquat dichloride, 5% sodium naphthalenesulfonate formaldehyde condensate, 2% ethylene oxide propylene oxide copolymer, triazole pyrimidinone equivalent to 0.18% of paraquat dichloride mass, 0.03% Ammonium benzoate sodium, 0.05% brilliant blue (acid blue 9#), 0.1% pyridine, and the rest was supplemented to 100% with mixed salt of ammonium sulfate and sodium sulfate (mass ratio 1:1). Then, mix the mixture with 20% water based on the weight of the mixture at room temperature to form a slurry, use the boiling granulation method: mix with hot air, heat up to ≥45°C, keep the temperature at 45-50°C, spray the mother liquor to granulate, Spray 1000~1200ml / 60~75 seconds each time, stop for 10 seconds, spray 8~10 times in total, compressed air pressure: 6kg / cm 2 , Vacuum exhaust control: inlet: 20 ~ 30mmH 2 O outlet: 350~400mmH 2 O, down to room temperature, forming particles with a particle size of 0.8-1.2mm. When used, it is formulated into an aqueous solution and spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com