Method for extracting cordycepin from cordyceps militaris rice medium under ultrahigh pressure

A culture medium, the technology of Cordyceps militaris, applied in the biological field, can solve the problems of unsuitable large-scale preparation of cordycepin and limited injection volume, etc., and achieve the effects of saving material consumption, high recovery rate and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

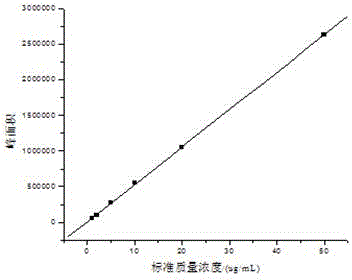

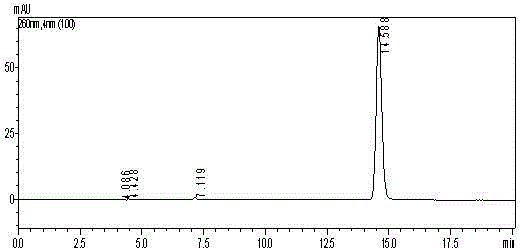

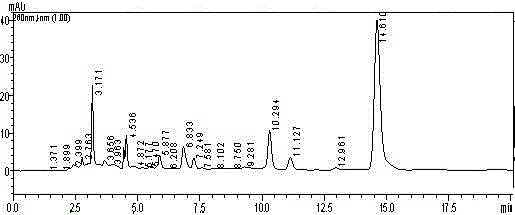

[0029] Take 30.0 g of Cordyceps militaris culture medium powder that has been crushed and passed through a 20-mesh sieve in a sealable plastic container, add distilled water at a material-to-liquid ratio of 1:70, stir evenly to make it fully wet, and use a vacuum packaging machine to degas it. Make sure that there are no air bubbles in the container, then put it into the ultra-high pressure treatment device, add tap water as the loading medium into the treatment chamber, use the depth gauge to check the liquid level until the height is appropriate, remove the depth gauge, push the plunger to the pressurized position, and close the supercharger. The high-voltage main engine protection door is ready to start pressurization. Set the pressure to 400MPa, and hold the pressure for 15 minutes. After the treatment is completed and the pressure is relieved, take out the container, pour out the extract and centrifuge (4000r / min, 10min), and discard the residue to obtain an ultra-hig...

Embodiment 2

[0034] The difference from Example 1 is that the used medium powder of Cordyceps militaris was crushed through a 60-mesh sieve, and its content was finally measured to be 41.09%, and the ultra-high pressure extraction yield was 1558.556ug / g, and the crude cordycepin was extracted by ultra-high pressure after freeze-drying The mass is 1.311g, and the purity of the dried crude cordycepin is 94.02% after separation by countercurrent chromatography.

Embodiment 3

[0036] The difference from Example 1 is that the used Cordyceps militaris culture medium powder is crushed through a 60-mesh sieve, and the pressure is 600Mpa. Finally, the content of cordycepin in the ultra-high pressure extract is measured to be 40.57%, and the extraction yield is 1393.71ug / g. The quality of the crude cordycepin extracted by ultra-high pressure after drying was 1.142g, and the purity of the dried crude cordycepin was 91.82% after separation by countercurrent chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com