Method and apparatus for automatic detection on large infusion production line

An automatic detection device and production line technology, applied in the direction of transportation and packaging, packaging, packaged food, etc., can solve the problems of low efficiency of manual detection, fatigue of detection personnel, high rate of missed detection, etc., to reduce the requirements of detection algorithms and realize seamless Humanize, remove the effect of slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

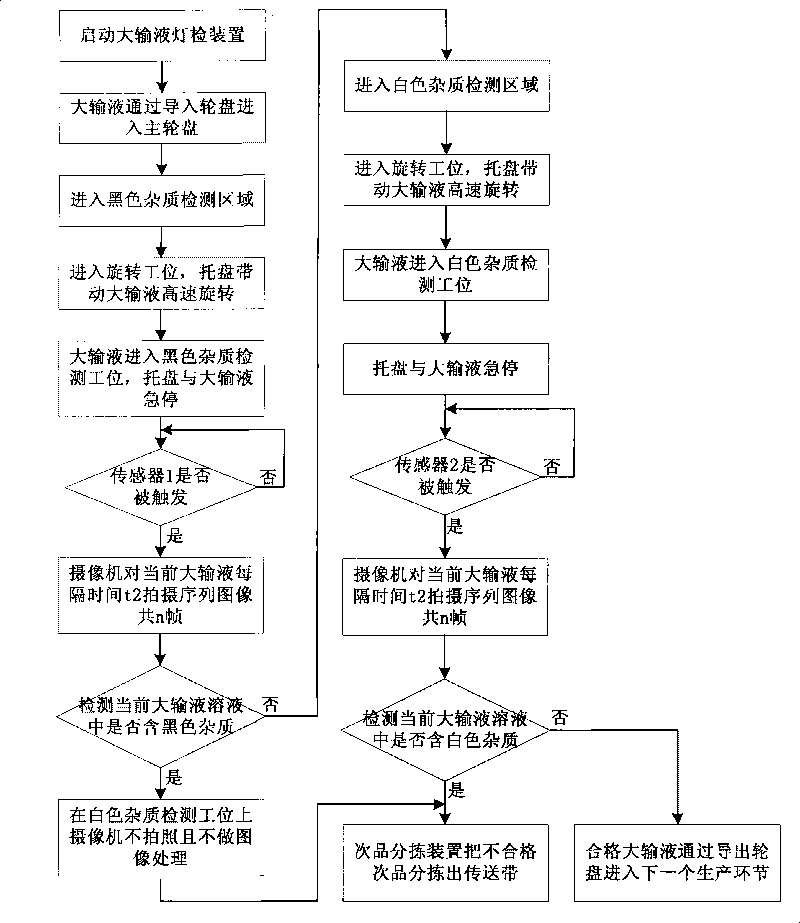

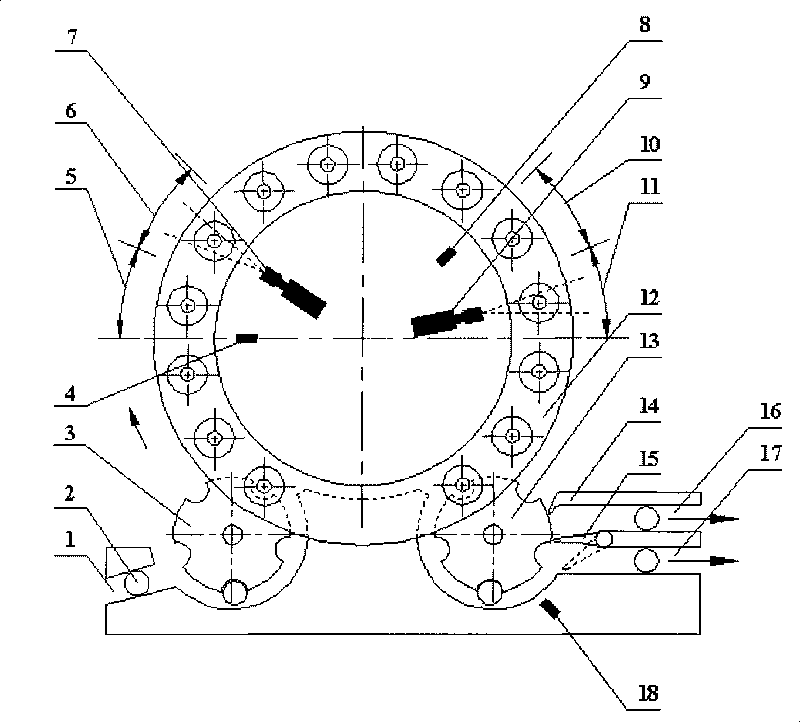

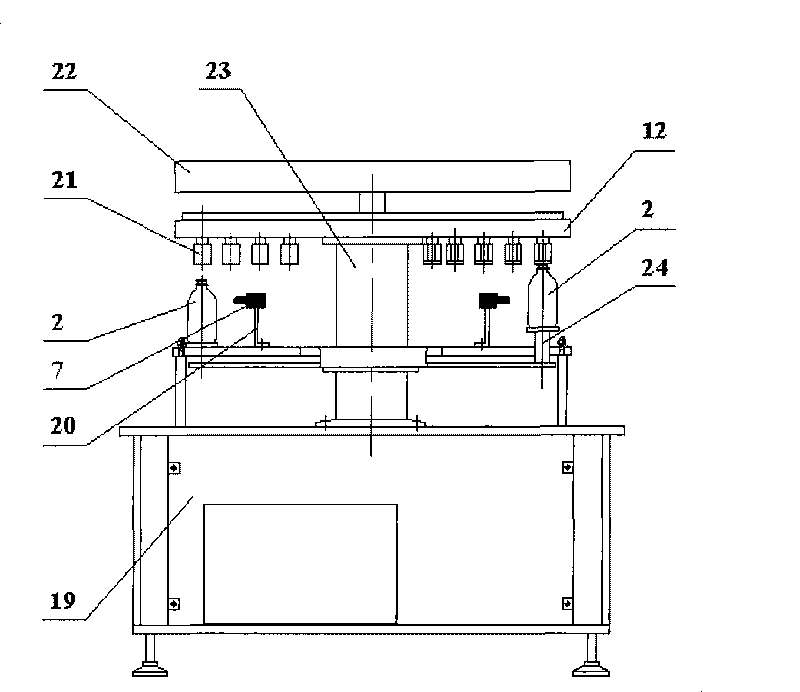

[0042] Aiming at the defects of manual inspection and traditional light inspection system, the present invention abandons the idea of single-frame image inspection. That is, the import roulette, main roulette and export roulette adopt intermittent operation, and the camera is fixed in continuous shooting mode to obtain stable multiple frames. image. Therefore, the present invention designs a gap-type rotation detection device, which can make the large infusion bottle rotate at a high speed and then stop suddenly, so that the liquid in the bottle and the impurities that may exist in the liquid can rotate, and the moving and stationary objects in the sequence image can be used in time. Distinguish the bottle body interference and the foreign matter inside the liquid from the difference in space, overcome the influence caused by the bottle body interference, and finally remove the unqualified large infusion products from the production line through the defective product sorting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com