Bidirectional cone poking and collecting mechanism for traffic road cone vehicle

A technology for road cone vehicles and traffic roads, which is applied in the field of two-way cone shifting and cone retracting mechanisms, which can solve the problems of low cone shifting efficiency, jamming, and small driving force, and achieve high shifting efficiency, stability, and dynamic power. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

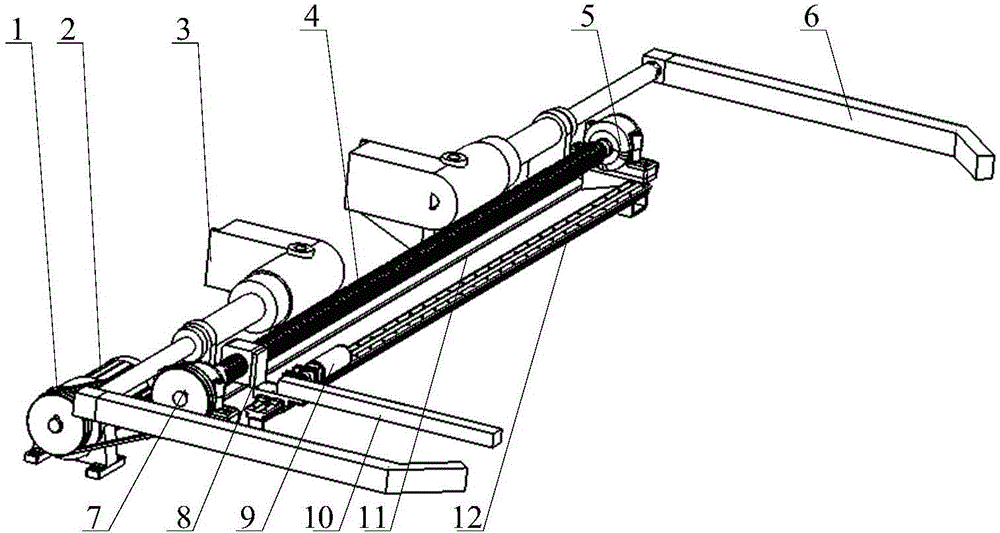

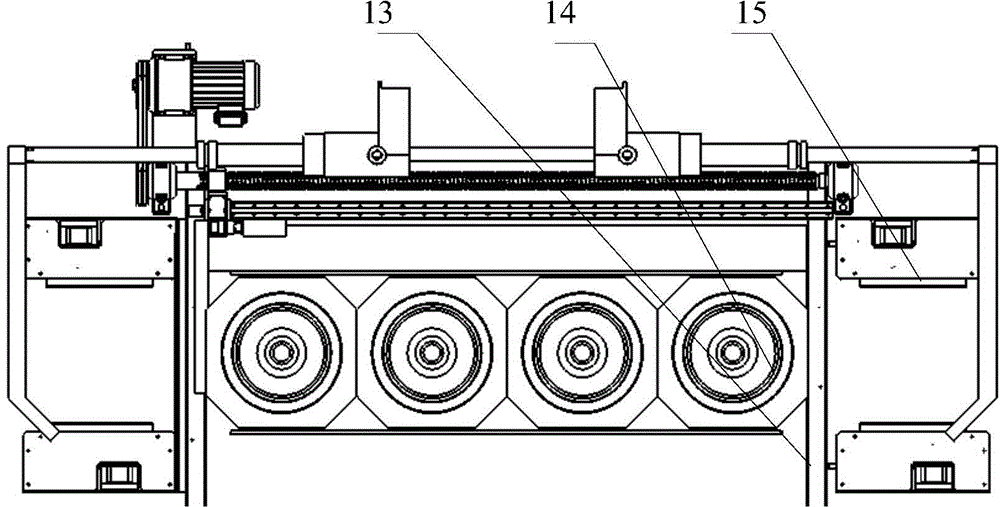

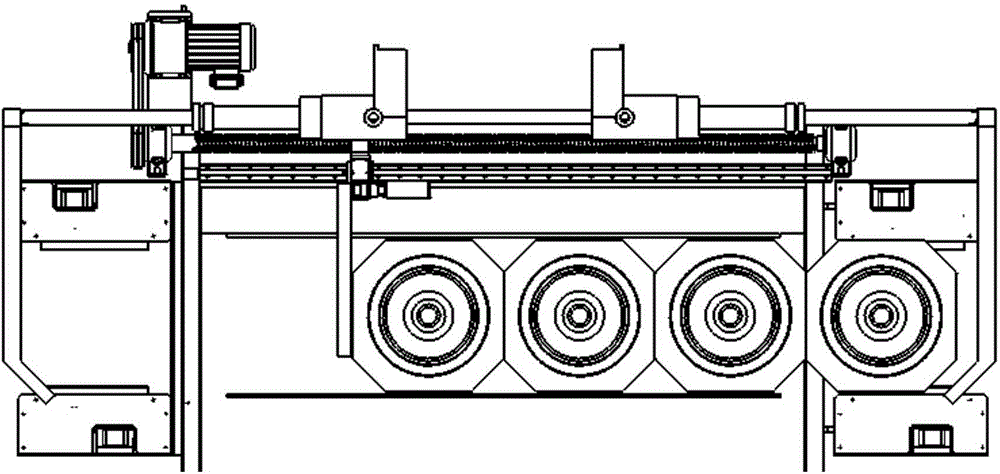

[0026] combine figure 1 :

[0027] A two-way cone shifting and cone retracting mechanism for traffic cone vehicles, including a synchronous belt 1, a stepping motor 2, a spiral swing telescopic oil cylinder 3, a screw screw rod 4, a bearing 5, a cone retracting tube 6, a pulley 7, and two-way movement Supporting plate 8, servo motor 9, taper pipe 10, support bracket 11 and linear guide rail 12; two spiral swing telescopic oil cylinders 3 and two bearings 5 are symmetrically fixed at both ends of support bracket 11 respectively, and stepping motor 2 It is arranged at one end of the support bracket 11, and the shafts at both ends of the screw rod 4 are matched with the two bearings 5 respectively. The shaft of the screw rod at one end close to the stepping motor 2 protrudes out from the bearings 5 for a certain distance, and the two pulleys 7 are respectively connected with the stepping motor 2. The output shaft of the motor 2 and the shaft of the screw screw 4 protruding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com