Low flow resistance cone valve

A technology of low flow resistance and cone valve, which is applied in the field of aerospace and aviation, can solve the problems that cannot meet the requirements of use, and achieve the effect of avoiding high pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

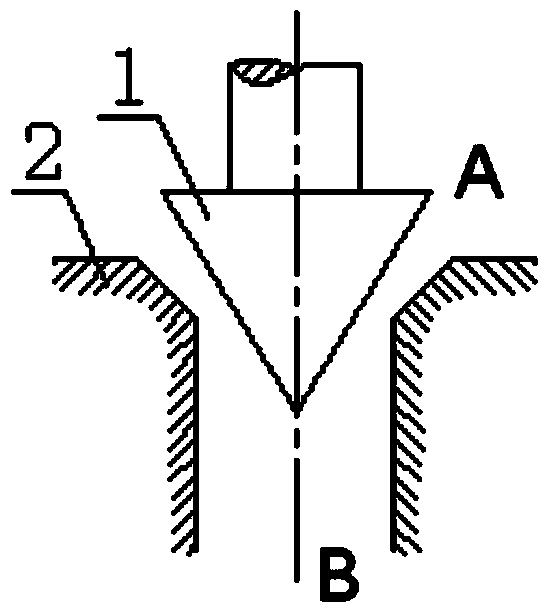

[0014] When the propellant is injected into the aerospace and aviation engines, when the test is carried out to the working condition close to 7500N, when the propellant is injected inside the valve body, a large fluid resistance will be generated (through many tests, at the working condition of 7500N, The flow resistance coefficient produced by the existing flow control valve is 2~2.7), so the system will generate a relatively high pressure drop, resulting in the existing cone valve not being able to adjust the flow rate of the engine under the 7500N working condition during the test, and unable to meet the requirements of the system test .

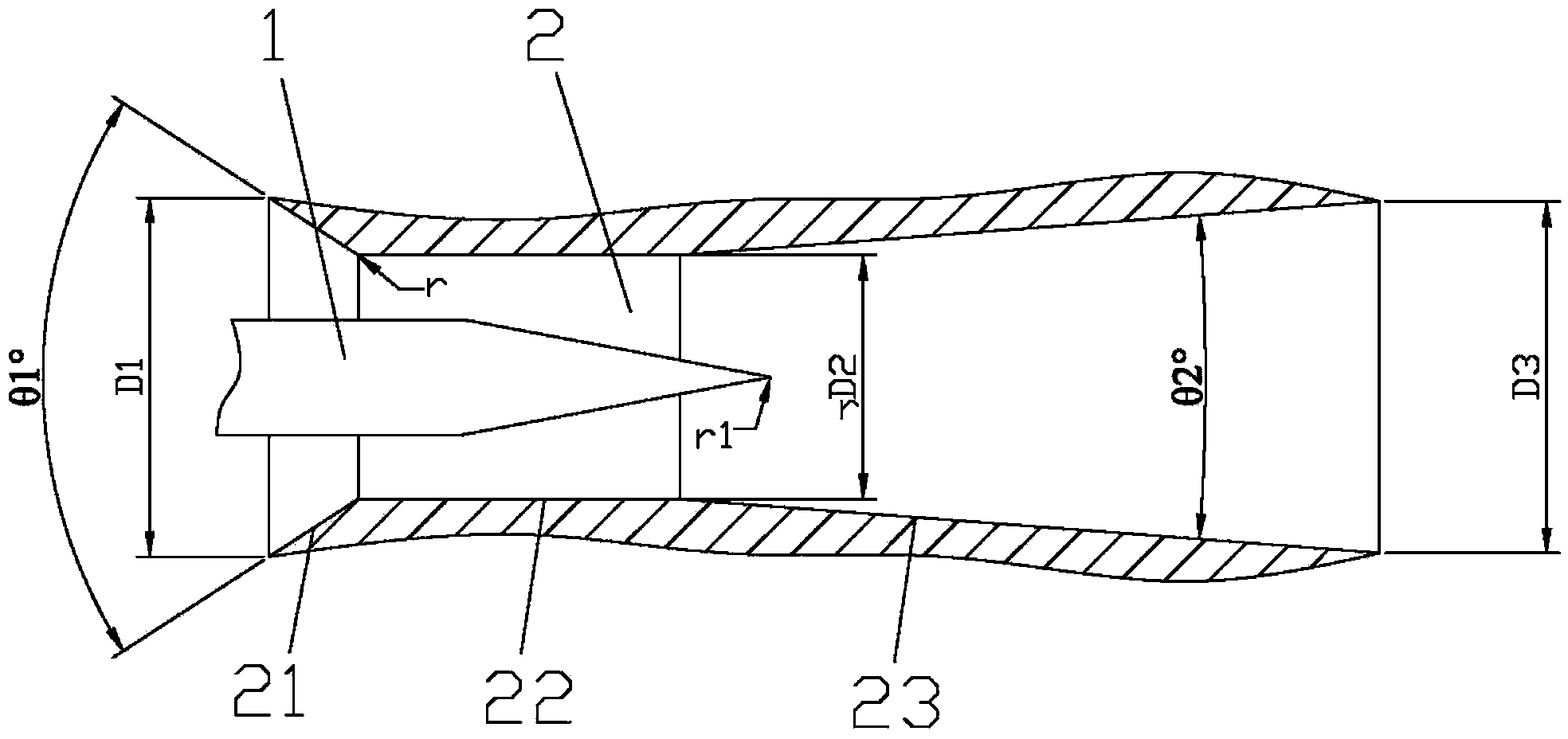

[0015] For this reason, the inventor of this case has carried out repeated tests and theoretical calculations, thereby designing a kind of low flow resistance cone valve, the improvement of this valve is: on the basis of the existing cone valve, the adjustment of the cone and the throttling tube Made improvements.

[0016] The following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com