Negative pressure pulse oscillating tool

A technology of pulse oscillation and tools, which is applied in vibration drilling, vibration generating devices, boreholes/well components, etc., can solve the problems of insignificant friction and drag reduction effects, complex structures of wear and drag reduction tools, and achieve pressure avoidance. drop too high effect

Pending Publication Date: 2019-10-25

石擎天

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a negative pressure pulse oscillating tool, which has the characteristics of high vibration amplitude and adjustable pressure pulse, and solves the problem of complex structure of wear and drag reduction tools in the prior art, and the effect of wear and drag reduction is not obvious. problem, improved drilling efficiency and shortened drilling time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 7

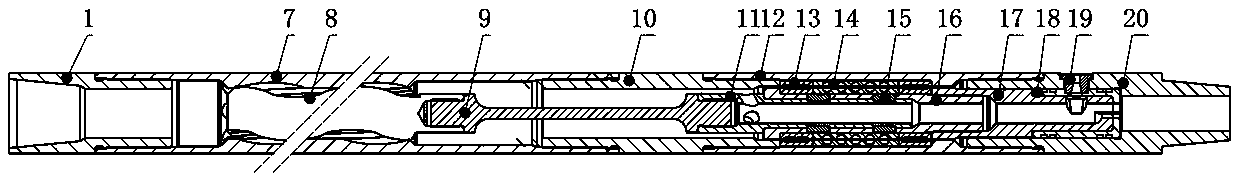

[0035] Embodiment 7 is basically similar to Embodiment 1, the difference is that the power part of Embodiment 7 is changed from the screw stator 7 and the screw rotor 8 to a turbine, and the turbine transmits power to the transmission shaft part and the rotary part.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

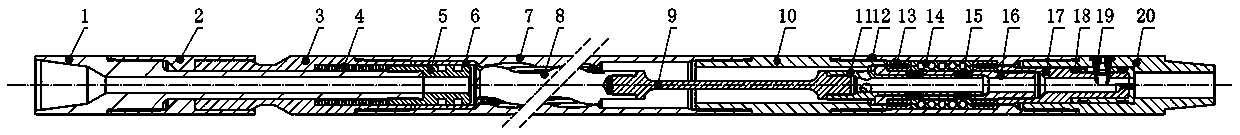

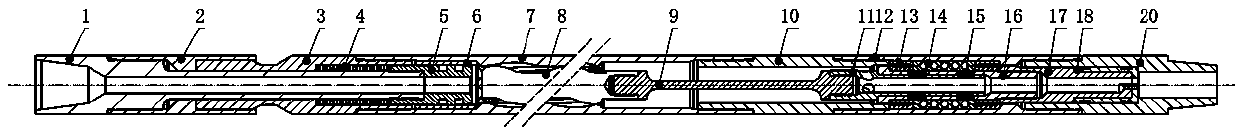

The invention discloses a negative pressure pulse oscillating tool which is integrally composed of four parts: an oscillating part, a power part, a transmission part and a rotating part. An upper joint is connected to an outer barrel of a spline through a thread, a plurality of reset disc springs are arranged in an oscillating short section, and a piston is in threaded connection to the oscillating short section to be sealed with a cylinder; a screw stator and a screw rotor provide power to the whole tool; a winding shaft is separately connected to the screw rotor and a water cap, and a bearing shaft connected to the water cap through a flat key forms the transmission part with a hard alloy bearing pack and a serial bearing pack; a movable valve rotates relative to a fixed valve and formsthe rotating part; a fluid enters into the tool through an inner runner of the upper joint, and is discharged from the tool from a bypass nozzle and the inner runner of a lower joint. The negative pressure pulse oscillating tool has the characteristics of being high in oscillating amplitude and capable of adjusting the pressure pulse, so that problems that a wear-reducing and resistance-reducing tool in the prior art is complex in structure, not obvious in wear-reducing and resistance-reducing effect and the like are solved, the drilling efficiency is improved and the drilling time is shortened.

Description

technical field [0001] The invention belongs to the technical field of downhole tools for oil and natural gas drilling engineering, and relates to a negative pressure pulse that can effectively reduce friction, transmit drilling pressure, and improve drilling speed and production efficiency in the production of complex structure wells such as extended-reach wells and long horizontal wells. Oscillating tool. Background technique [0002] In the oil and gas industry, with the gradual development of the application of highly deviated wells and horizontal wells in drilling engineering, especially the drilling depth of the horizontal section continues to increase. The friction between the drill string and the drill string and the well wall or the inner wall of the casing is increasing, which seriously affects the drilling speed, and sometimes causes the string to bend or even lock. In order to solve the above problems, many companies at home and abroad have successively develope...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B7/24E21B28/00

CPCE21B7/24E21B28/00

Inventor 彭文玥石擎天刘毅吕方

Owner 石擎天

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com