Low temperature Fischer-tropsch synthetic oil hydrofining and / or hydrogenation heterogeneous cracking system and technology

A technology for hydroisomerization cracking and Fischer-Tropsch synthetic oil, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, and can solve the problems of high device investment and operation cost, large bed temperature gradient and Complex process and other problems, to achieve the effect of long operation period, prolong operation period, reduce device investment and operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

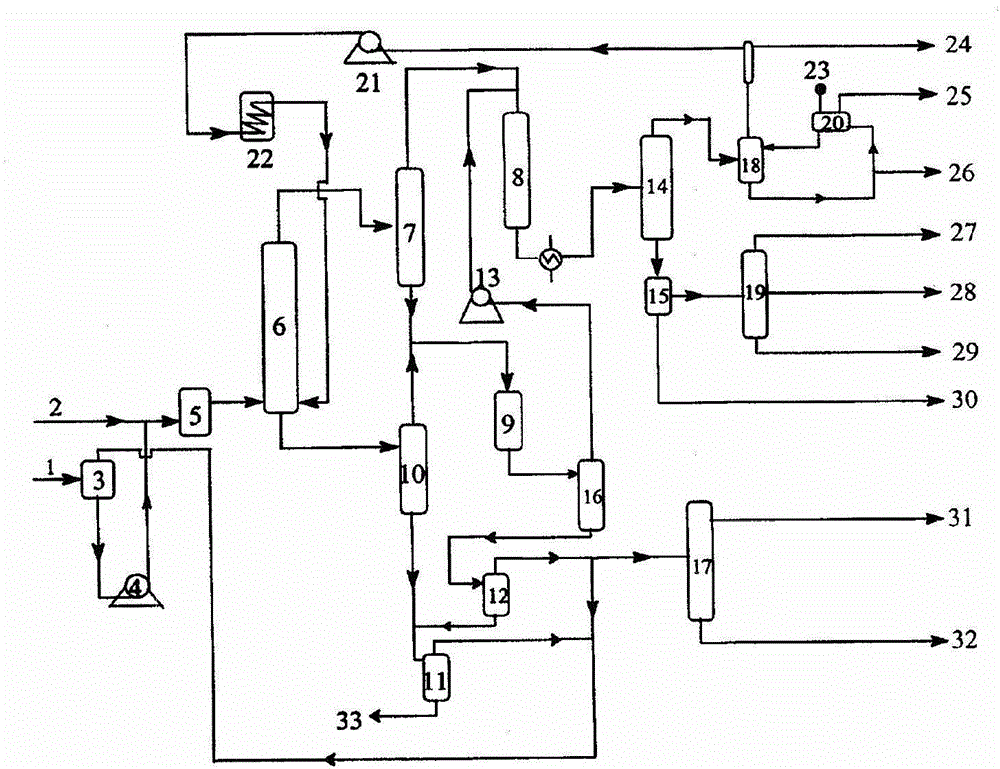

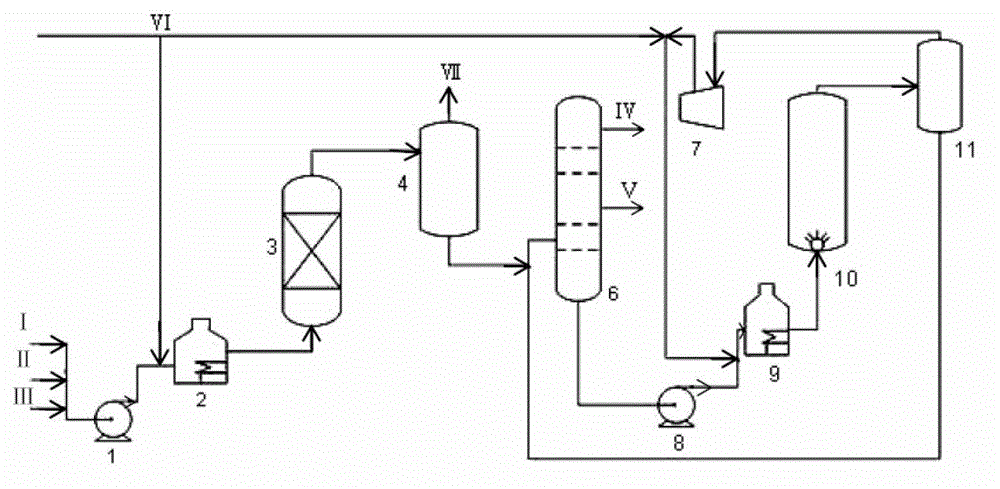

[0067] use figure 1 The system shown performs hydrofinishing and hydroisomerization cracking of low temperature Fischer-Tropsch oil.

[0068] The low-temperature Fischer-Tropsch synthetic whole distillate oil from Shenhua coal-based syngas is used as raw material, and its properties are shown in Table 1. Liquid Phase Hydrofining Catalyst as NiO-MoO 3 -P 2 o 5 / Al 2 o 3 , purchased from Shandong Qilu Catalyst Factory, model is FF-26, wherein NiO is 3.5wt%, MoO 3 13.5wt%, P 2 o 5 1.4wt%, TiO 2 1.4%; slurry bed / ebullating bed hydroisomerization cracking catalyst is NiO-WO 3 / Al 2 o 3 , purchased from Shandong Qilu Catalyst Factory, model is FC-14, wherein NiO is 5wt%, WO 3 The specific properties of the catalyst are shown in Table 2. The operating conditions of fixed-bed liquid-phase hydrofinishing and slurry-bed / ebullating-bed hydroisomerization cracking are listed in Table 3, the properties of naphtha fraction, one of the products, are listed in Table 4, and the pr...

Embodiment 2

[0082] use figure 1 The system shown hydrofinishes cryogenic Fischer-Tropsch oil, i.e. shut down figure 1 The system shown is a slurry bed / ebullating bed hydroisomerization cracking unit.

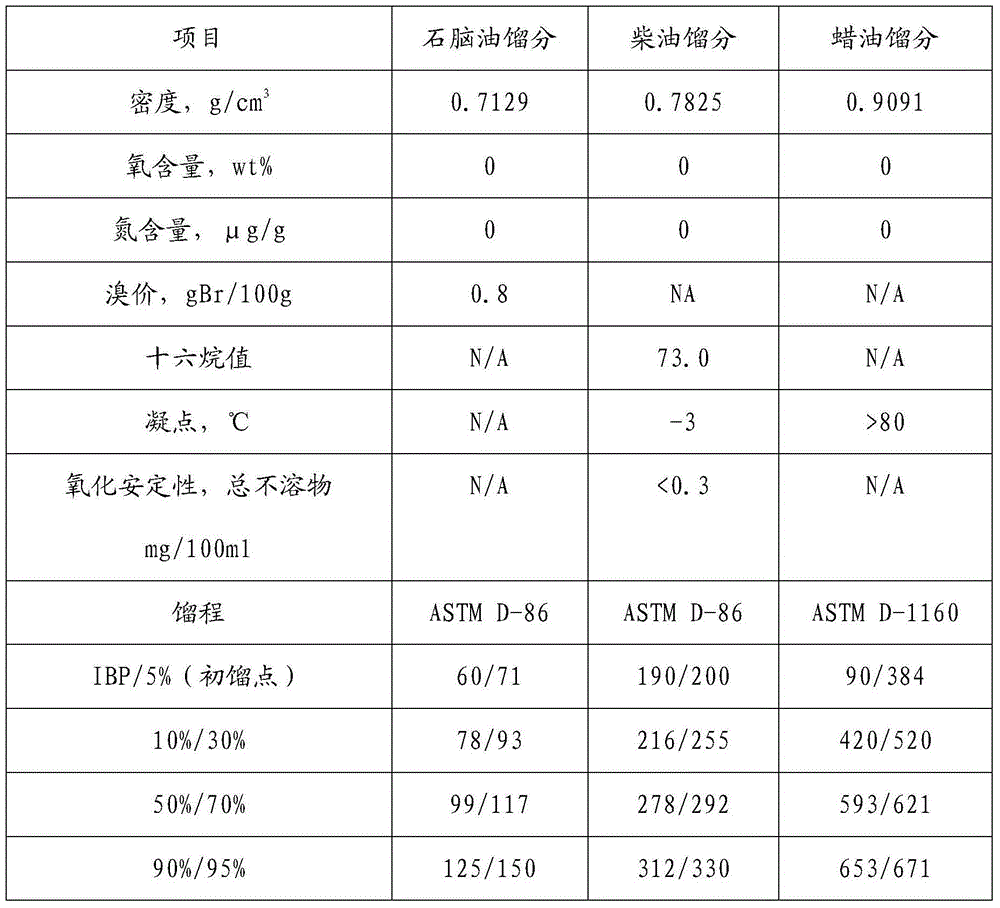

[0083] With the raw material identical with embodiment 1, use the liquid phase hydrorefining catalyst identical with embodiment 1 and adopt the liquid phase hydrorefining unit identical with embodiment 1 and operating condition to carry out liquid phase hydrorefining, from product fractionation column Naphtha, diesel oil and wax oil (or tail oil) are obtained from the mixture, and their properties are shown in Table 6.

[0084] Table 6 Properties of Naphtha, Diesel Oil and Wax Oil After Hydrofinishing of Fischer-Tropsch Synthesis Whole Fraction Oil

[0085]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com