Leakage point detecting device for liquid container

A technology for testing equipment and liquid containers, which is applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum for liquid tightness measurement, which can solve the problems of time-consuming, labor-intensive, and cumbersome processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

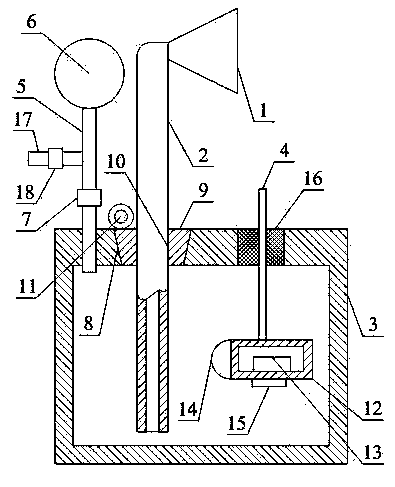

[0034] Such as figure 1 As shown, the leak point detection equipment for liquid containers includes: suction cup 1; delivery pipe 2 whose upper end communicates with suction cup 1; liquid storage box 3, which communicates with the rear end of delivery pipe 2, and liquid storage box 3 It is made of transparent plastic; the pull bar 4 runs through the top of the liquid storage box 3, the upper end of the pull bar 4 is located outside the liquid storage box 3, and the lower end of the pull bar 4 is located inside the liquid storage box 3; the indicator box 12, the indicator box 12 is connected to the lower end of the pull bar 4; the battery 13, the battery 13 is arranged in the indicator box 12; the indicator light 14, the indicator light 14 is arranged on the outer surface of the indicator box 12 and connected with the battery 13 through a wire; Sensitive switch 15, the pressure sensitive switch 15 is arranged on the outer surface of the indicator box 12 and connected to the wir...

Embodiment 2

[0039] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes a branch pipe 5 communicating with the top of the liquid storage box 3 ; and a flexible plastic ball 6 communicating with the end of the branch pipe 5 .

[0040] It also includes a branch pipe B17 arranged on the branch pipe A5, a one-way valve B18 arranged on the branch pipe B17, and a one-way valve A7 arranged on the branch pipe A5; the one-way valve A7 is located between the liquid storage box 3 and the branch pipe B17 In between, the one-way valve A7 is configured to allow the gas in the liquid storage box 3 to enter the flexible plastic ball 6; the one-way valve B18 is configured to allow the gas in the flexible plastic ball 6 to discharge out of the branch pipe B17 .

[0041] Squeeze the flexible plastic ball 6, the gas in the flexible plastic ball 6 is discharged through the one-way valve B18, loosen the flexible plastic ball 6, and the gas in the liquid storage box 3 is suck...

Embodiment 3

[0043] Such as figure 1 As shown, in this embodiment, on the basis of any one of the above-mentioned embodiments, the top of the liquid storage box 3 is provided with a tapered through hole 8 with a large upper part and a smaller lower part; it also includes a tapered plug 9, a tapered plug 9 is provided with a circular through hole 10;

[0044] After the tapered plug 9 is inserted into the tapered through hole 8, the tapered through hole 8 squeezes the tapered plug 9 to deform the tapered plug 9, so that the inner wall of the circular through hole 10 is close to the delivery pipe 2 The outer surface is used to achieve sealing and prevent foreign matter from entering the liquid storage box 3 and affecting the detection results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com