Manufacturing method of climbing plant fixer

The technology of a vine plant and its manufacturing method, which is applied in the field of vine plant fixer manufacturing, can solve problems such as being easily affected by wind damage, female flowers being injured, and not making money, so as to avoid the impact of wind damage, mature on the market early, and increase the fruit setting rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

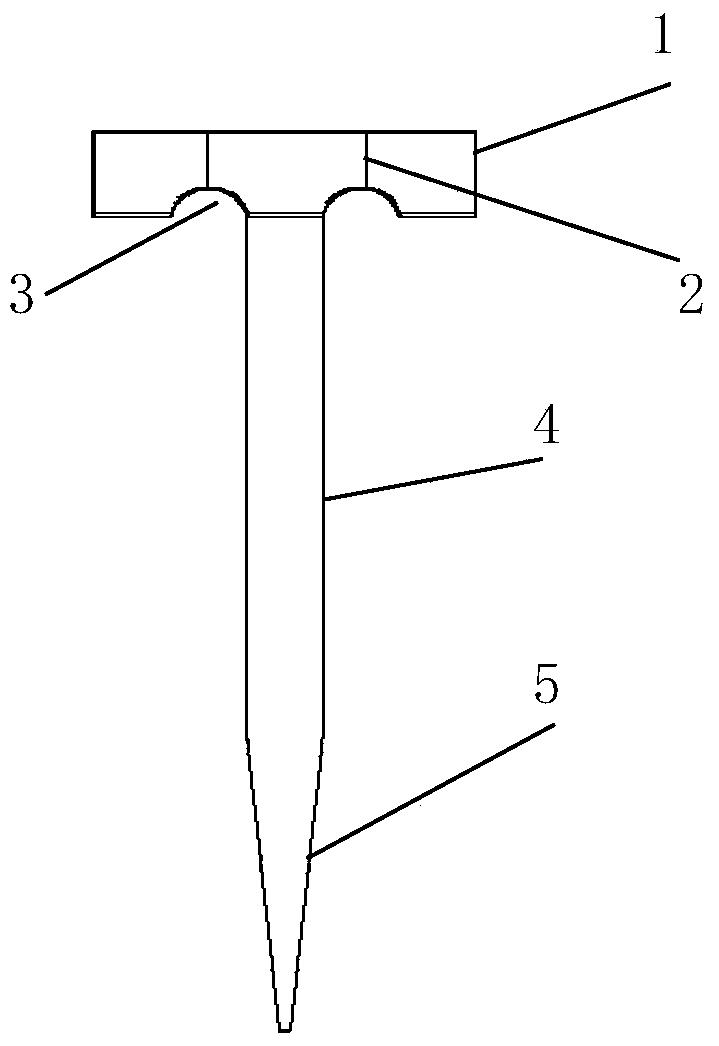

Embodiment 1

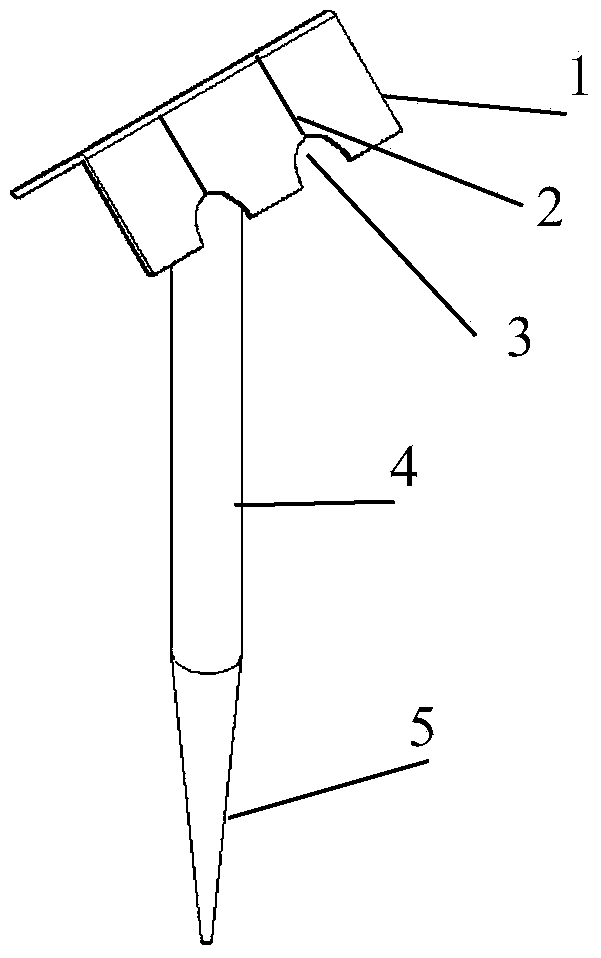

[0018] Embodiment 1: As shown in the figure, a vine plant fixer is composed of a pressure plate 1 and a pressure column 4, and is characterized in that a pressure column 4 is arranged at the bottom of the pressure plate 1, and a cone 5 is arranged at the lower end of the pressure column 4; the vine plant fixer The manufacturing method of the invention: the vine plant holder in the shape of "a" is obtained by injection molding, and the vertical grid line 2 is arranged on the top of the pressure plate 1 to divide the surface of the pressure plate 1 into several areas, and the semicircular pressure groove 3 is arranged on the lower side of the pressure plate 1 That is, the bottom of the pressing plate 1 forms an inclined space 6 at the front and rear sides of the pressing column 4, forms a semicircular pressure groove 3 at the left and right sides of the pressing column, and forms a cone 5 at the lower end of the pressing column 4.

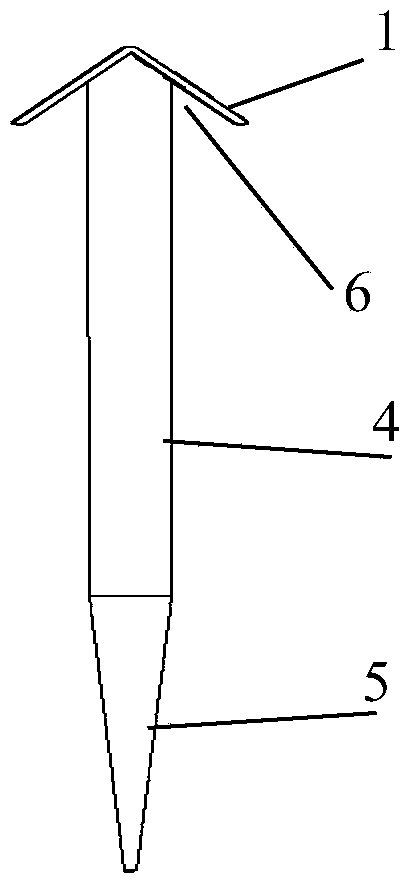

Embodiment 2

[0019] Embodiment 2: As shown in the figure, a vine plant fixer is composed of a pressure plate 1 and a pressure column 4, and is characterized in that a pressure column 4 is arranged at the bottom of the pressure plate 1, and a cone 5 is arranged at the lower end of the pressure column 4. The vine plant fixer The manufacturing method of the invention is characterized in that the process is as follows: Extrude a long strip in the shape of "a" with an extrusion die, put the long strip into a stamping die, and obtain a single vine plant fixer after stamping, that is, press out a vertical grid on the pressing plate 1 Line 2 divides the pressure plate 1 into several areas, and punches out a semicircular pressure groove 3 and a pressure column 4 under the pressure plate 1, that is, the lower part of the pressure plate 1 forms an inclined space 6 on the front and rear sides of the pressure column 4. The left and right sides of 4 form a semicircular pressure groove 3, and the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com