Hard suitcase and manufacturing method thereof

A production method and hard case technology, applied to luggage, travel goods, clothing, etc., can solve the problems of transportation cost waste, multiple spaces, waste, etc., and achieve the effects of reduced transportation costs, simple production equipment, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

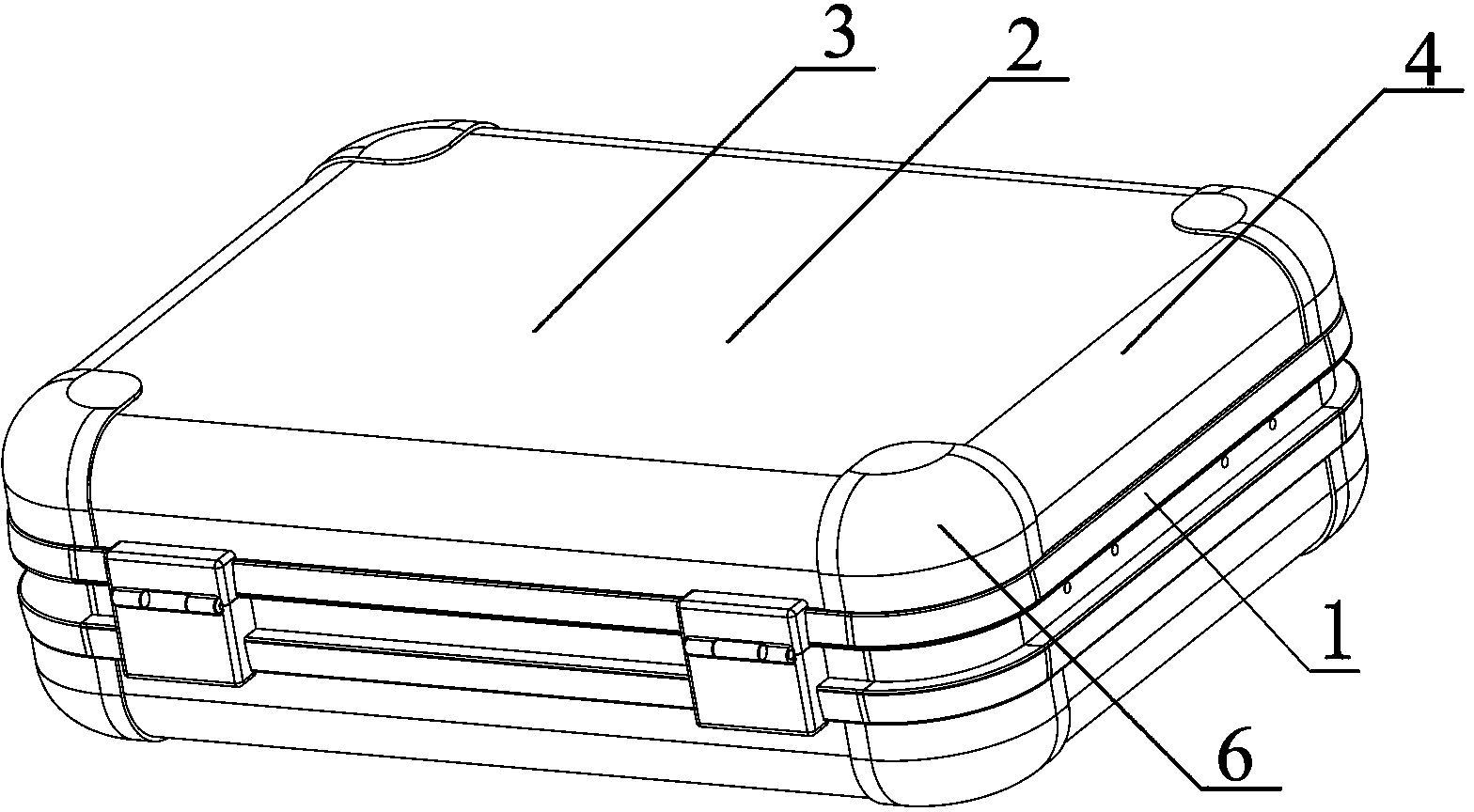

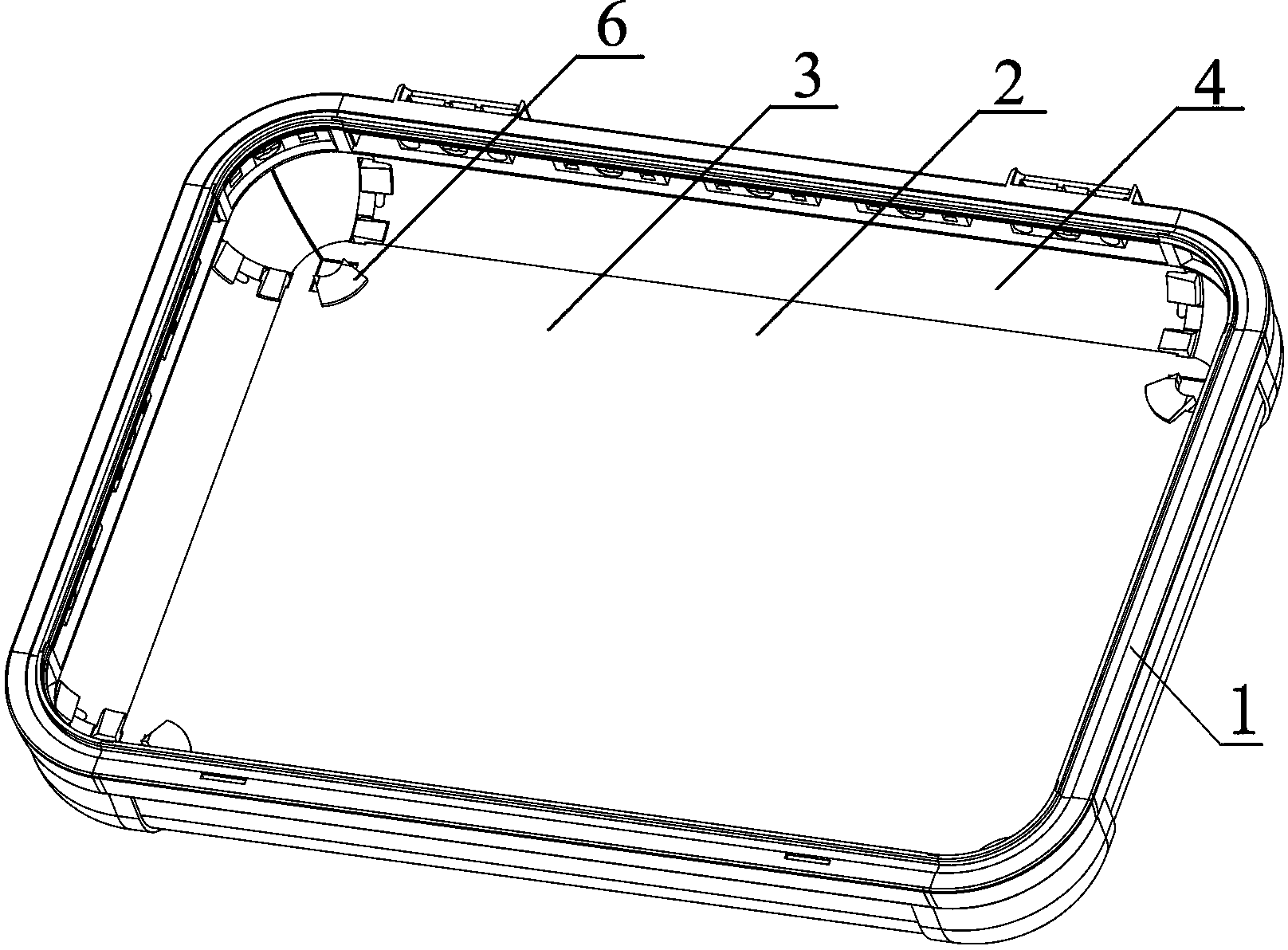

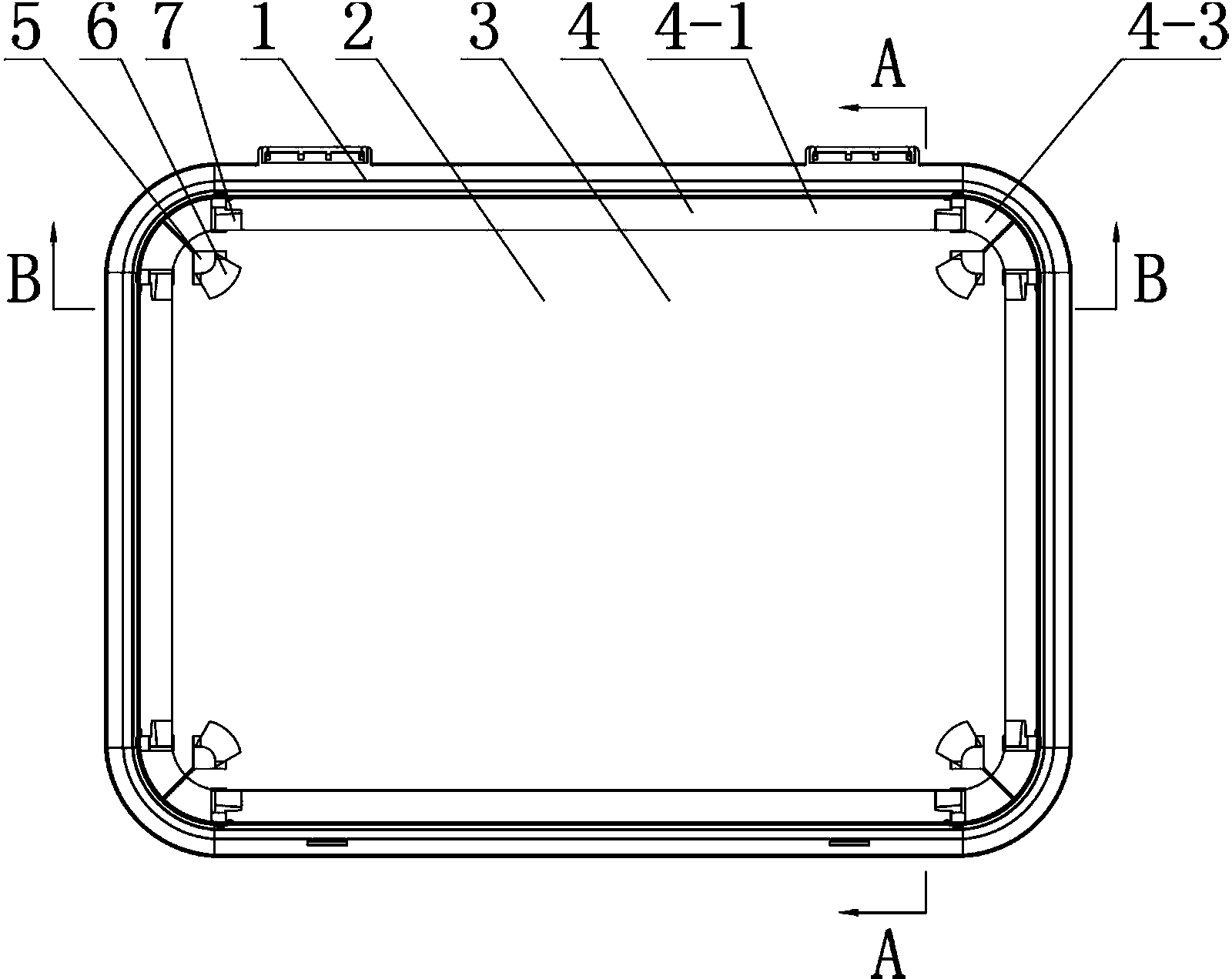

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11As shown, the present invention provides a travel hard case, including a frame body 1 and a case cover 2, and the case cover 2 includes a flat bottom surface 3 and four bending surfaces 4, and the flat bottom surface 3 and the bending surfaces 4 are Integral molding, and the four bending surfaces 4 are in the same plane as the flat bottom surface 3 before bending, the flat bottom surface 3 is the bottom surface of the box cover 2, and the four bending surfaces 4 are bent and matched with the frame body 1 to form a box The height elevation of the cover 2, the bending surface 4 includes a connection part 4-1, an insertion part 4-2 and a splicing part 4-3, and the connection part 4-1 is the connection between the bending surface 4 and the flat bottom surface 3 The connection part, the insertion part 4-2 is the matching part betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com