Soldering flux and soldering paste

A flux and solder paste technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of flux leakage, insufficient effect, and deterioration of voids, etc., to achieve stable printability and maintain Printability, effect of suppressing bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

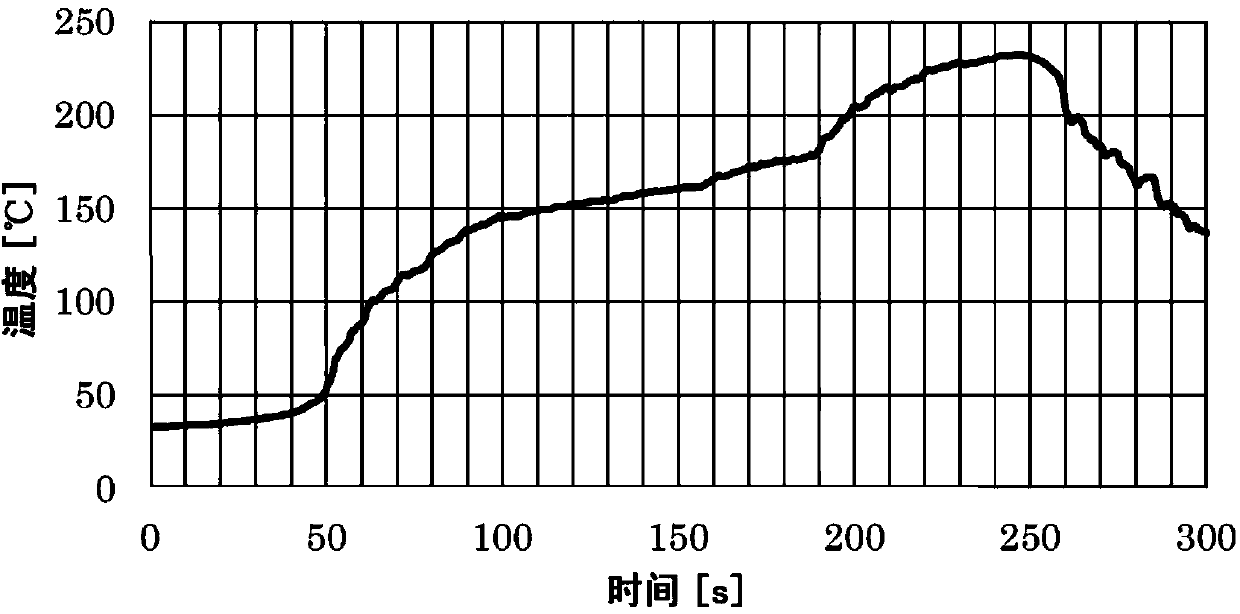

[0077] An example is given below to describe the present invention in detail. In addition, the determination of each characteristic value in an Example was implemented based on the following criteria. In addition, the composition and compounding quantity of each flux and each solder paste are shown in Table 1. In addition, the units of the numerical values described in Table 1 are all weight %.

[0078]

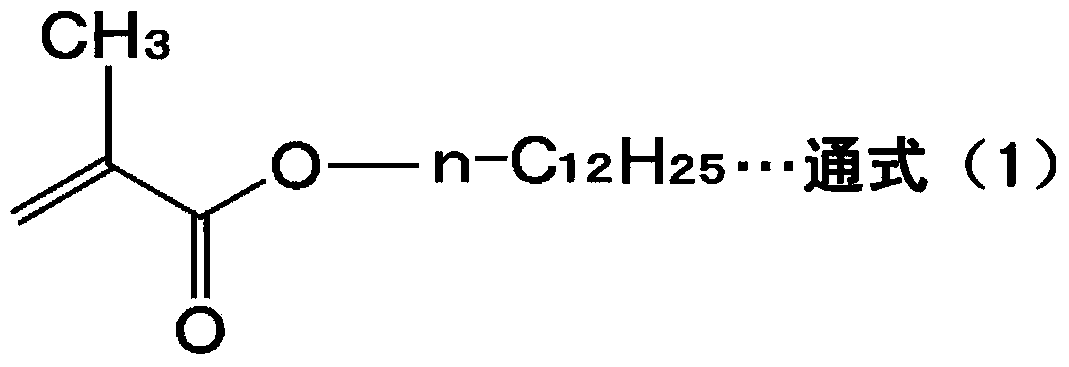

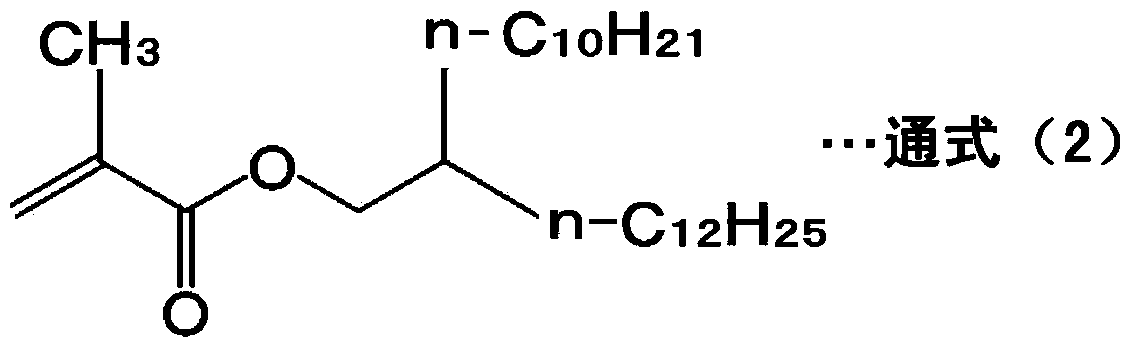

[0079] A solution 1 obtained by mixing 40% by weight of a compound represented by the following general formula (1) and 60% by weight of a compound represented by the following general formula (2) was produced.

[0080] [chemical formula 1]

[0081]

[0082] [chemical formula 2]

[0083]

[0084] 200 g of diethylhexanediol was placed in a 500 ml 4-necked flask equipped with a stirrer, a reflux condenser, and a nitrogen gas introduction tube, and heated to 110°C. Thereafter, 0.2 to 5% by weight of an azo-based radical initiator (dimethyl 2,2'-azobis(2-methylpropi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap