Collagen device is partially attached to the surface of the product

A collagen and product technology, which is applied to the field of local lamination of collagen devices on the surface of products, can solve the problems of accumulation, affecting the quality of lamination, errors between collagen and positioning holes, steel sheets and positioning holes, etc., so as to maintain relative dimensions and avoid intermediate errors. , maintain a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

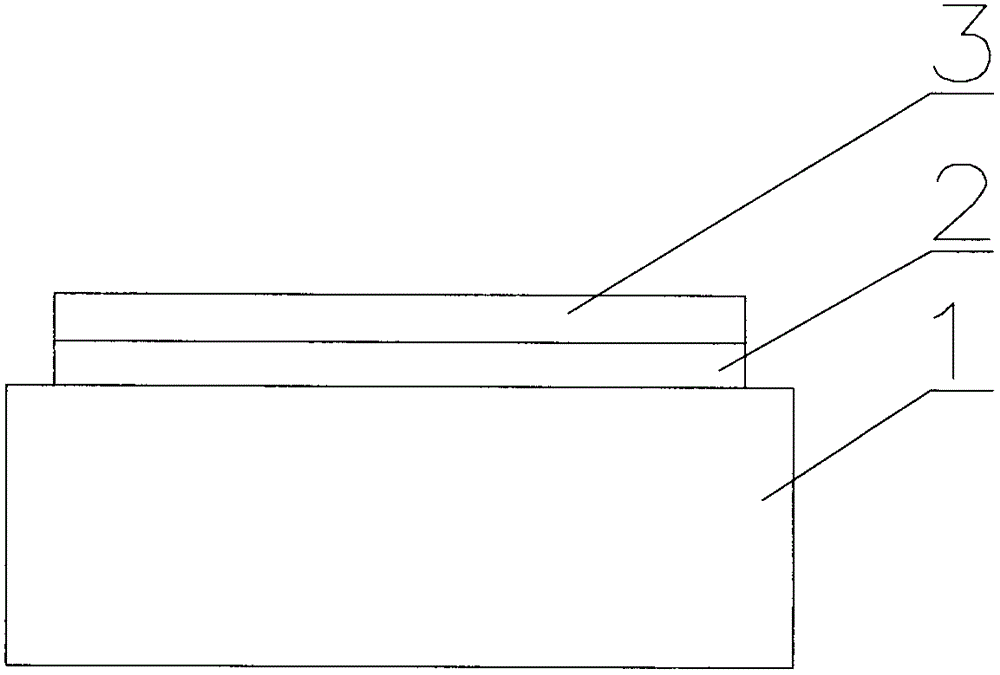

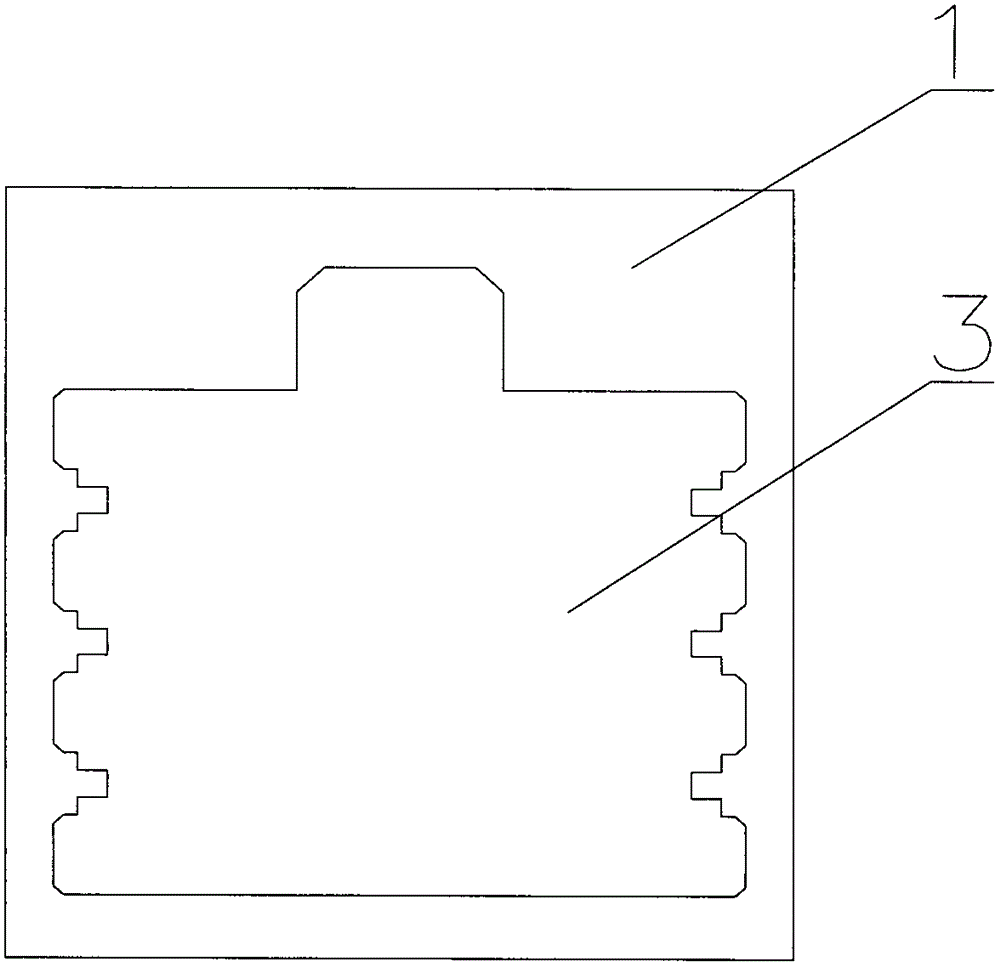

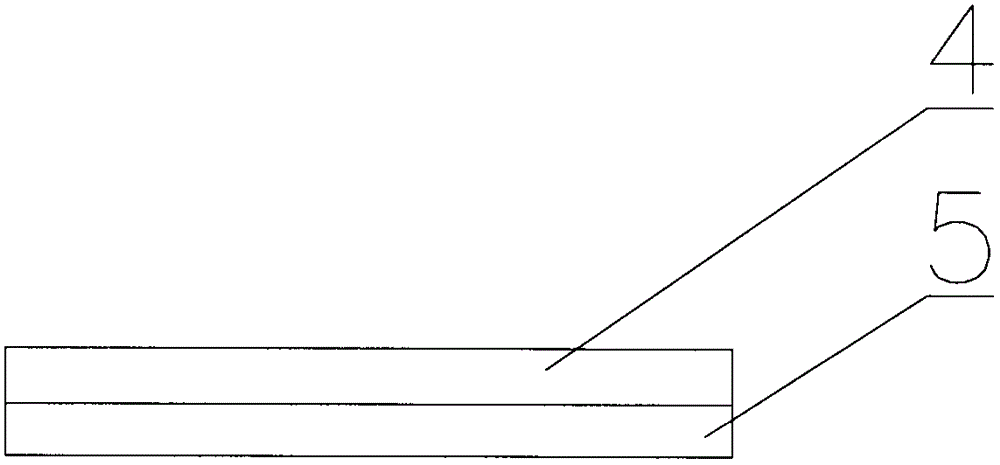

[0020] Such as Figures 1 to 6 Shown is a device for partially laminating collagen on the surface of a product, including an upper layer, a lower layer, a steel sheet 6, a collagen deviation paper 5, and a collagen 4, and a positioning plate 3 is fixed between the lower supporting plate 1 and the positioning plate 3 through the supporting plate 1. A layer of silica gel layer 2 is laid, and on; the steel sheet 6 is installed on the upper layer; the collagen away from the paper 5 is installed on the positioning plate 3, and the collagen 4 is arranged on the collagen away from the paper 5; There are steel sheets 6 and collagen facing away from the edge positioning structure of the paper 5 .

[0021] The collagen departure paper 5 is divided into several identically shaped units along the length direction, each unit is provided with a piece of collagen 4, and the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com