Method of manufacturing of birefringent film and application of the film

A manufacturing method and birefringence technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as wrinkles, difficulty in high production efficiency, and small relaxation effect, and achieve suppression of birefringence, high production efficiency, and improved display The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

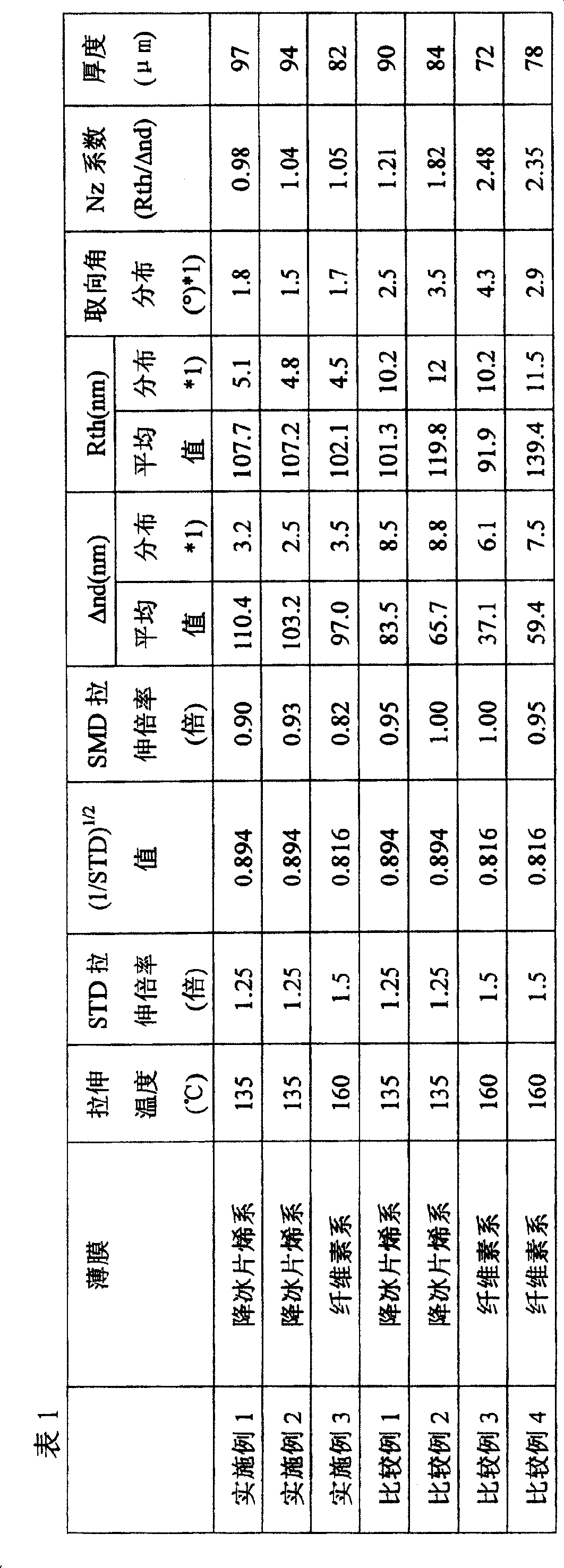

[0115] An unstretched norbornene-based film with a thickness of 100 μm and a width of 600 mm (manufactured by JSR Corporation, trade name “ ゼオノア"), while shrinking it in the longitudinal direction, a birefringent film (thickness 97 μm) was produced. In addition, the stretching temperature was 135° C., the STD in the width direction was 1.25 times, and the SMD in the above-mentioned longitudinal direction was 0.90 times. For the obtained birefringent film, the in-plane retardation (Δnd =(nx-ny)×d) and thickness direction retardation (Rth=(nx-nz)×d) and orientation angle distribution. An average value was calculated for the in-plane phase difference and thickness direction phase difference, and the Nz coefficient was calculated from the average value.

[0116] The results are shown in Table 1.

[0117] In addition, nx, ny, and nz represent the refractive indices of the X-axis (slow axis), Y-axis, and Z-axis directions of the above-mentioned birefringent film, respectively. Th...

Embodiment 2

[0119] A birefringent film (thickness 94 μm) was produced in the same manner as in Example 1 except that the SMD in the longitudinal direction was 0.93 times. The results are shown in Table 1.

Embodiment 3

[0121] A birefringent film (thickness 82 μm) was produced in the same manner as in Example 1 using an unstretched cellulose-based film with a thickness of 96 μm and a width of 600 mm (“KA Film” manufactured by Heneyo Co., Ltd.). In addition, the stretching temperature was 160° C., the STD in the width direction was 1.5 times, and the SMD in the length direction was 0.82 times. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com