Chip resetting method and device

A reset method and reset device technology, applied in the field of printing, can solve the problems of economic pressure, environmental protection, inability to be reused, low reset success rate, etc., and achieve good environmental protection value, high reset rate, and poor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiment of chip reset method:

[0027] The present invention provides a method for resetting a chip installed on a printer consumable. The method for resetting the chip includes: after receiving the command sent by the printer, judging the command sent by the printer, and sending different commands to corresponding command processing Module, the command is executed by the corresponding command processing module.

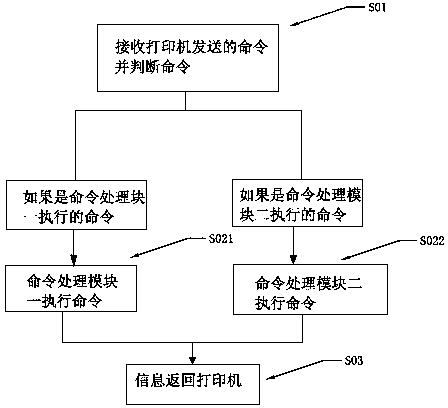

[0028] Specifically, such as figure 1 As shown, first execute step S01: receive the command sent by the printer and judge the command; if the received command is executed by command processing module 1, then transmit the command to command processing module 1; then execute step S021: command processing module 1 Execute corresponding operations; finally execute step S03: return the information to the printer. In step S01, if the command received is the command executed by the command processing module two, then the command is communicated to the command pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com