Compact structure rotating type feeding device

A technology of feeding device and compact structure, which is applied in the field of rotary feeding device, can solve the problems of overflow, high labor intensity of operators, low degree of automation, etc., achieve smooth feeding, facilitate logistics organization, and reduce production management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

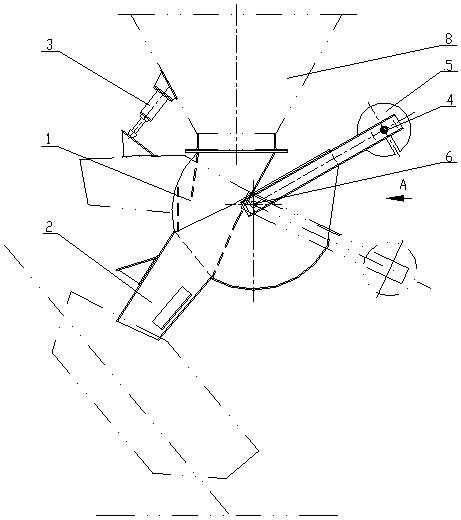

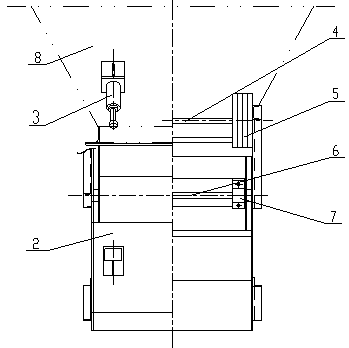

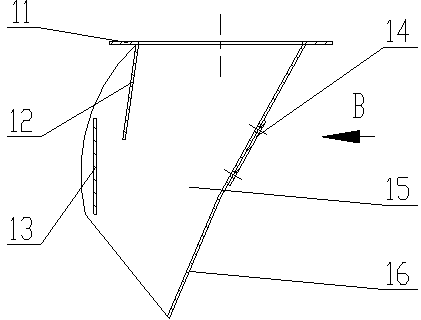

[0021] see figure 1 and figure 2 , the compact structure rotary feeding device of the present invention is suitable for loading materials in the lower part of the single-bucket elevator. It is set according to the volume of the vehicle body. The transition hopper transfers materials from the storage yard to it through a loader or a conveyor. This hoist is mainly composed of a driving device, a feeding device, a material cart with rollers, and a guide rail. The guide rail includes left and right sides, which are divided into upper part, lower part and vertical part. The feeding device is usually suspended under the bulk material transition hopper 8 of metal or concrete structure.

[0022] A rotary feeding device with a compact structure, including: a revolving door seat 1, a revolving door 2, a buffer 3, a double-ended screw 4, a counterwei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com