Spring buckle type medium and low speed maglev transportation system track telescopic adjustment structure

A transportation system and telescopic adjustment technology, which is applied in the field of rail transportation systems to maintain smooth lines, improve laying efficiency, and reduce interaction forces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

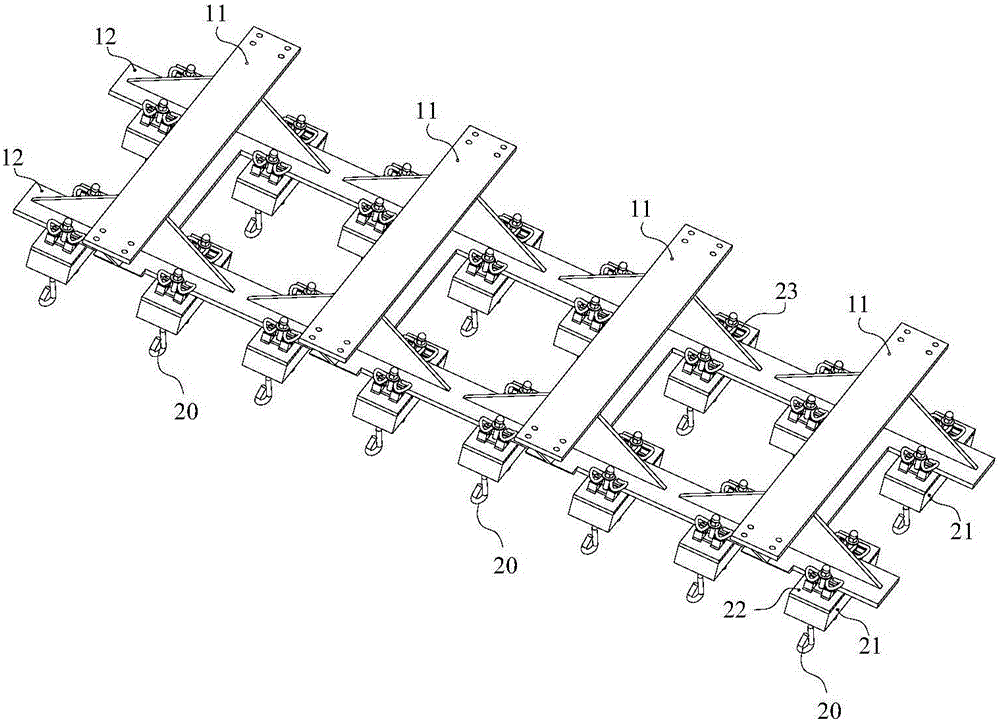

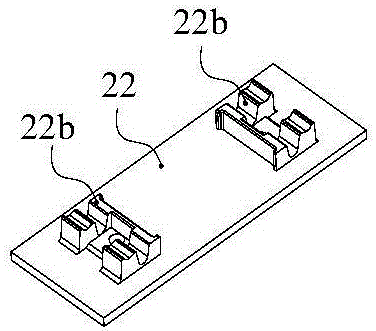

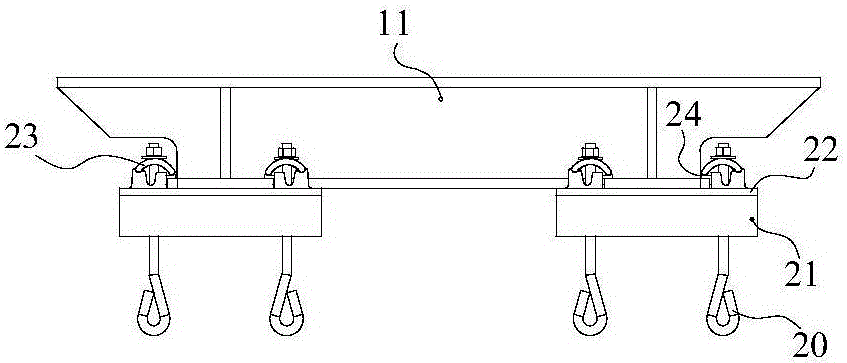

[0021] refer to Figure 5 , figure 1 , figure 2 and 6 , the telescopic adjustment structure of the rail of the middle and low-speed maglev transportation system of the elastic strip withholding type of the present invention includes: a rib plate type rail row, the main body of which is composed of sleeper units 11 arranged at longitudinal intervals and two longitudinally connected at intervals arranged horizontally and fixedly connected together. Plates 12, ribs 13 are welded between each sleeper unit 11 and the longitudinal connecting plate 12; rail bearing platforms 21 are arranged in two rows at transverse intervals on the bridge beam body; backing plates 22 are arranged on the top surface of each rail bearing platform 21 and Between the bottom surfaces of the longitudinal connecting plates 12, the top surface has elastic fixing protrusions 22b a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com