Device and method for detecting damage to a conveying pipeline

A technology for damage detection and transportation pipelines, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of no dynamic real-time monitoring methods, etc., and achieve reliable results, simple and easy methods, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

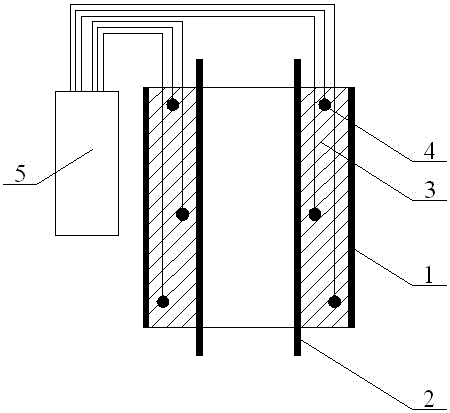

[0016] Such as figure 1 As shown, a pipeline damage detection device includes an outer wall tube 1 and an inner wall tube 2, the inner wall tube 2 is located in the outer wall tube 1, and the middle area formed between the outer wall tube 1 and the inner wall tube 2 is filled with a filling liquid 3, filled The liquid 3 is a liquid or paste-like substance; several pressure sensors 4 are arranged in the middle area, both ends of the middle area are closed, and the pressure sensors 4 are connected to an external monitoring system 5 .

[0017] A method for detecting damage to a delivery pipeline, using the above-mentioned detection device, and including the following steps:

[0018] (1) Static detection

[0019] (1) When the inner wall pipe 2 is empty, use the external monitoring system 5 to read the monitoring value P0 of the nth pressure sensor;

[0020] (2) Fill the inner tube 2 with liquid or pasty substance, and close both ends of the inner tube 2, apply a certain pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com