LED lamp and supporting structure thereof

A technology of LED lamps and supporting structures, applied in lighting devices, light sources, fixed lighting devices, etc., can solve the problems of high cost, poor efficiency, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

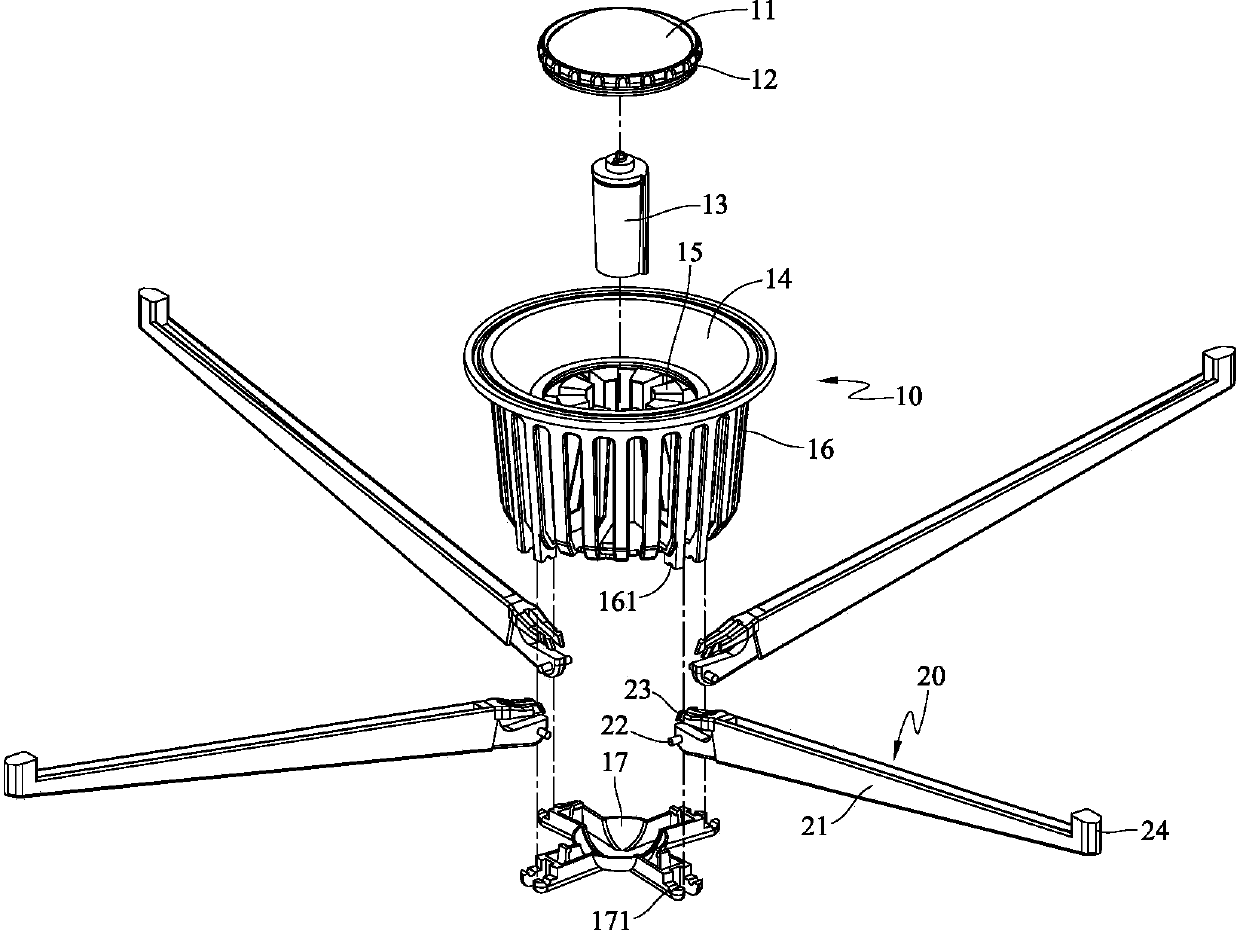

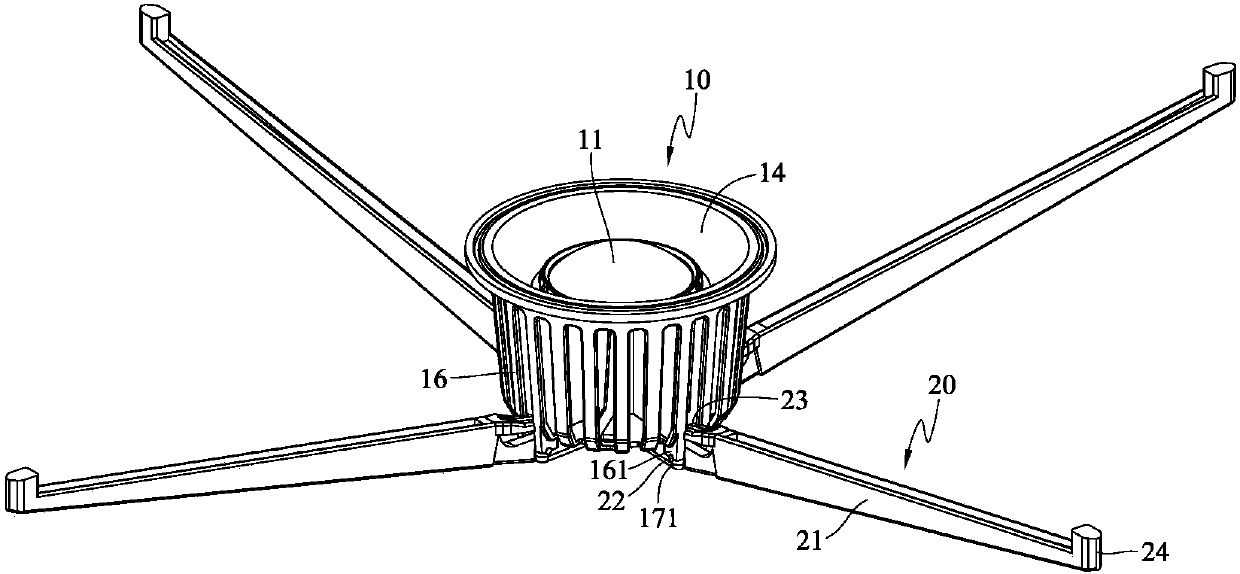

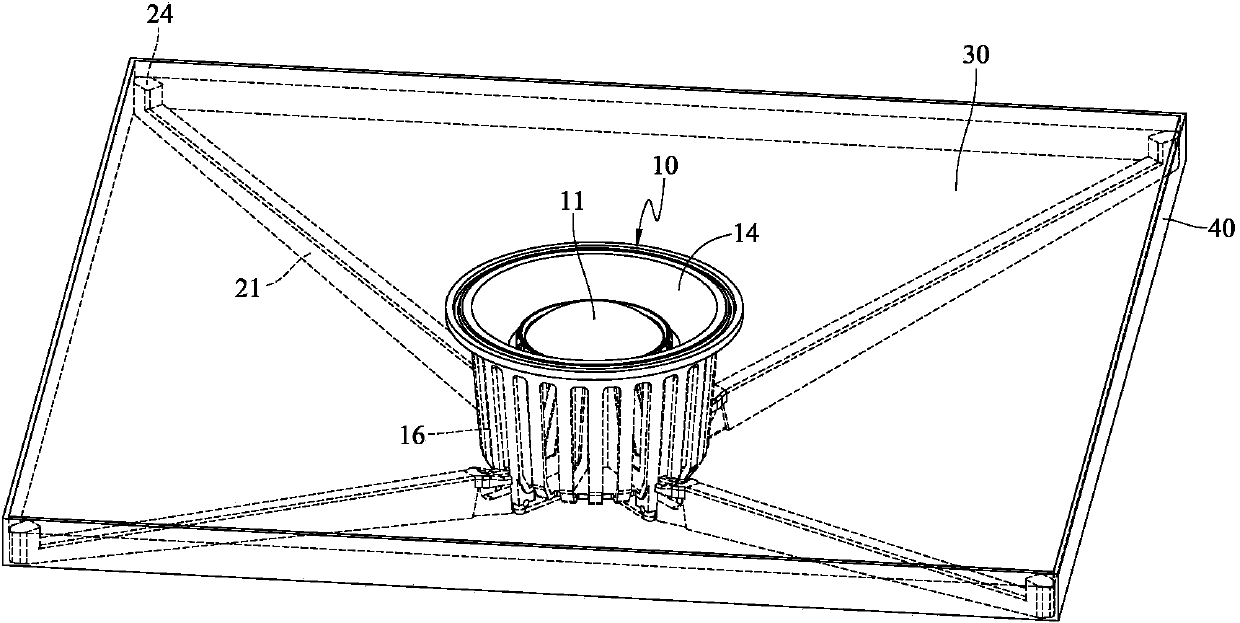

[0062] According to the LED lamp structure of the present invention, please refer to figure 1 , is an exploded view of the first embodiment of the LED lamp structure of the present invention.

[0063] The main structure of the LED lamp 10 of the present invention includes a light source module 11, a base body 16, and a connection module 20. A light cup 14 is arranged in front of the base body 16, and an accommodating space is arranged inside, and the light source module 11 is connected to At the front end of the base body 16, the lamp source module 11 is provided with a corresponding receiving portion to connect with the drive module 13, the drive module 13 can be accommodated in the accommodation space of the base body 16, and the drive module 13 can City power (AC) is converted into working power, and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com