Radiating device and testing device with radiating device

A technology of heat dissipation device and heat dissipation block, which is applied in the testing of machine/structural components, cooling/heating device of lighting device, measuring device, etc., which can solve the problems of inaccurate data, easily damaged LED, and small size of LED.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

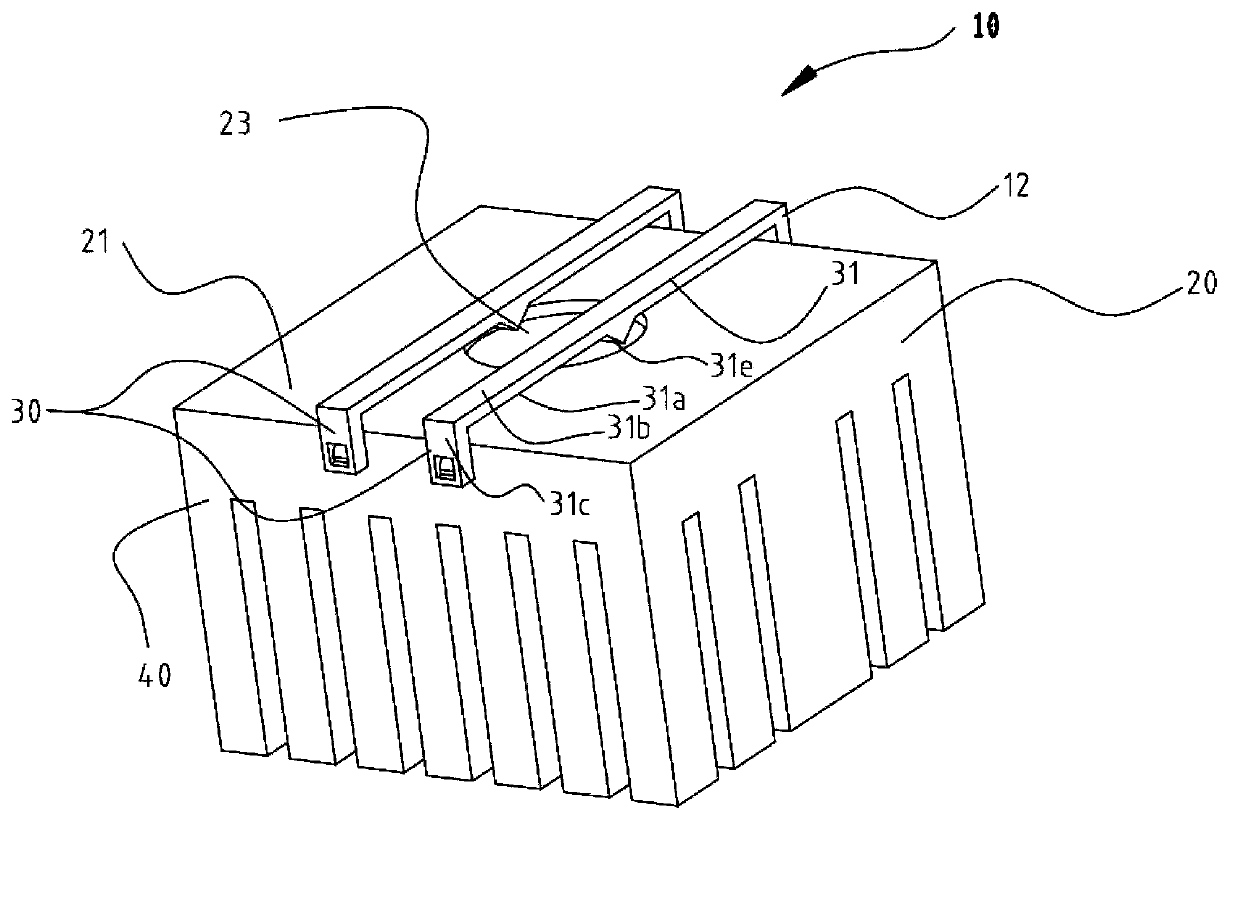

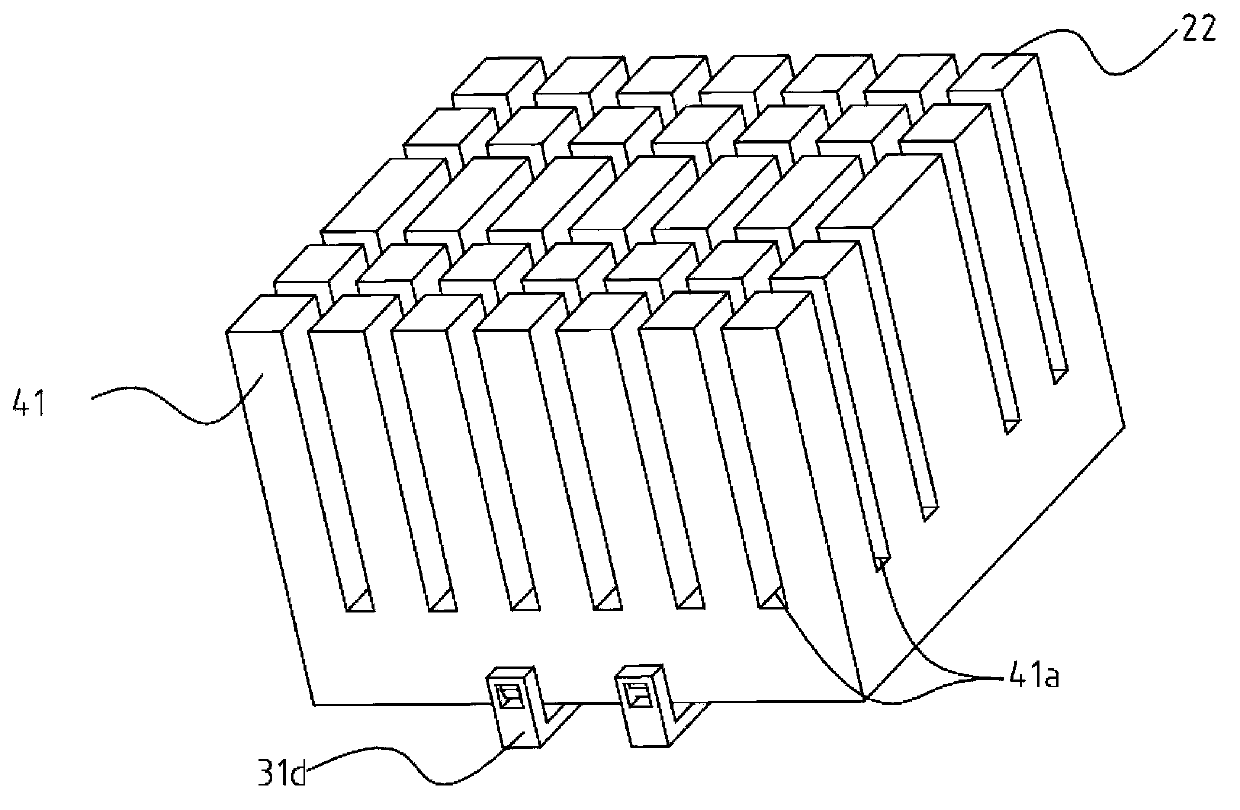

[0019] Please refer to Figure 1 to Figure 2 , the present invention provides a test device for LEDs (not shown), which includes a heat sink 10 and a detection device (not shown).

[0020] The heat sink 10 includes a housing 20 and a fixing structure 30 for fixing the LED on the housing 20, the housing 20 is oppositely provided with a first end surface 21 and a second end surface 22, the first One end surface 21 is equipped with the fixing structure 30; the second end surface 22 forms a heat dissipation structure 40 for dissipating heat from the LED.

[0021] Because the present invention installs the LED on the housing 20, dissipates the heat generated on the LED to the housing 20, and then uses a detection device to detect the heat on the housing 20, thereby testing the LED...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com