Patents

Literature

37results about How to "Efficient and convenient testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

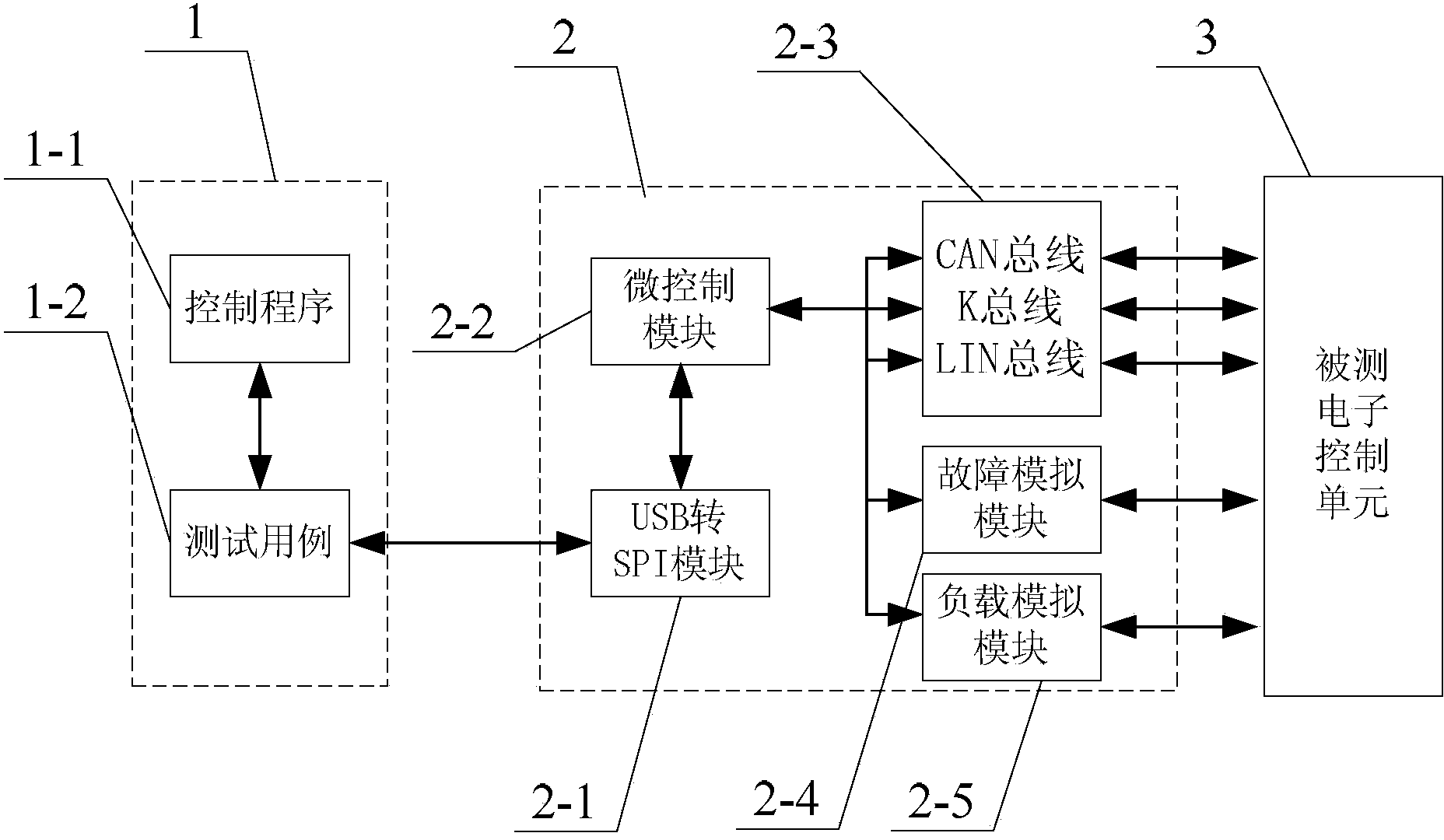

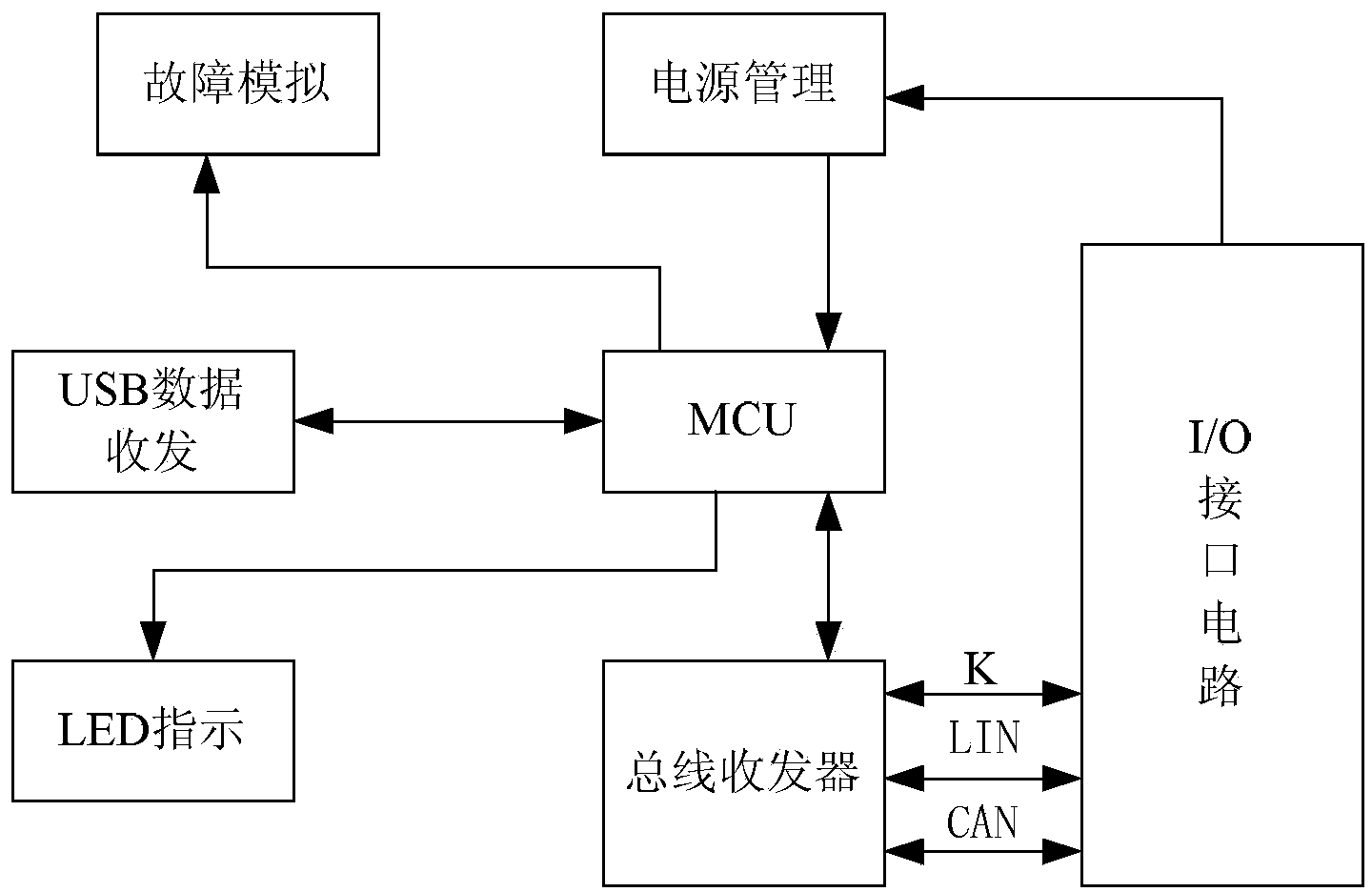

Automobile ECU measurement system based on hardware-in-loop simulation

InactiveCN104076814AEasy to testEfficient testingElectric testing/monitoringAutomotive engineeringRepeatability

The invention discloses an automobile ECU measurement system based on hardware-in-loop simulation, and belongs to the technical field of automobile ECU tests. The automobile ECU measurement system based on hardware-in-loop simulation aims to solve the problems that in an existing test mode of automobile ECUs, the test cost is high and error sources are unclear. According to the automobile ECU measurement system based on hardware-in-loop simulation, tests of a real automobile are converted into the ECU tests in a virtual automobile through the hardware-in-loop simulation technology, the characteristics of the real automobile are simulated through an upper computer and a lower computer, the tests are conveniently and efficiently carried out, the repeatability is good, and many dangerous conditions of the real automobile can be simulated; in the early stage of automobile research and development, the characteristics of the complete automobile are simulated to test the functions and performance of the ECUs, and then ECUs passing the tests are combined to form a complete automobile system. The automobile ECU measurement system based on hardware-in-loop simulation is used for testing of the automobile ECUs.

Owner:HARBIN INST OF TECH

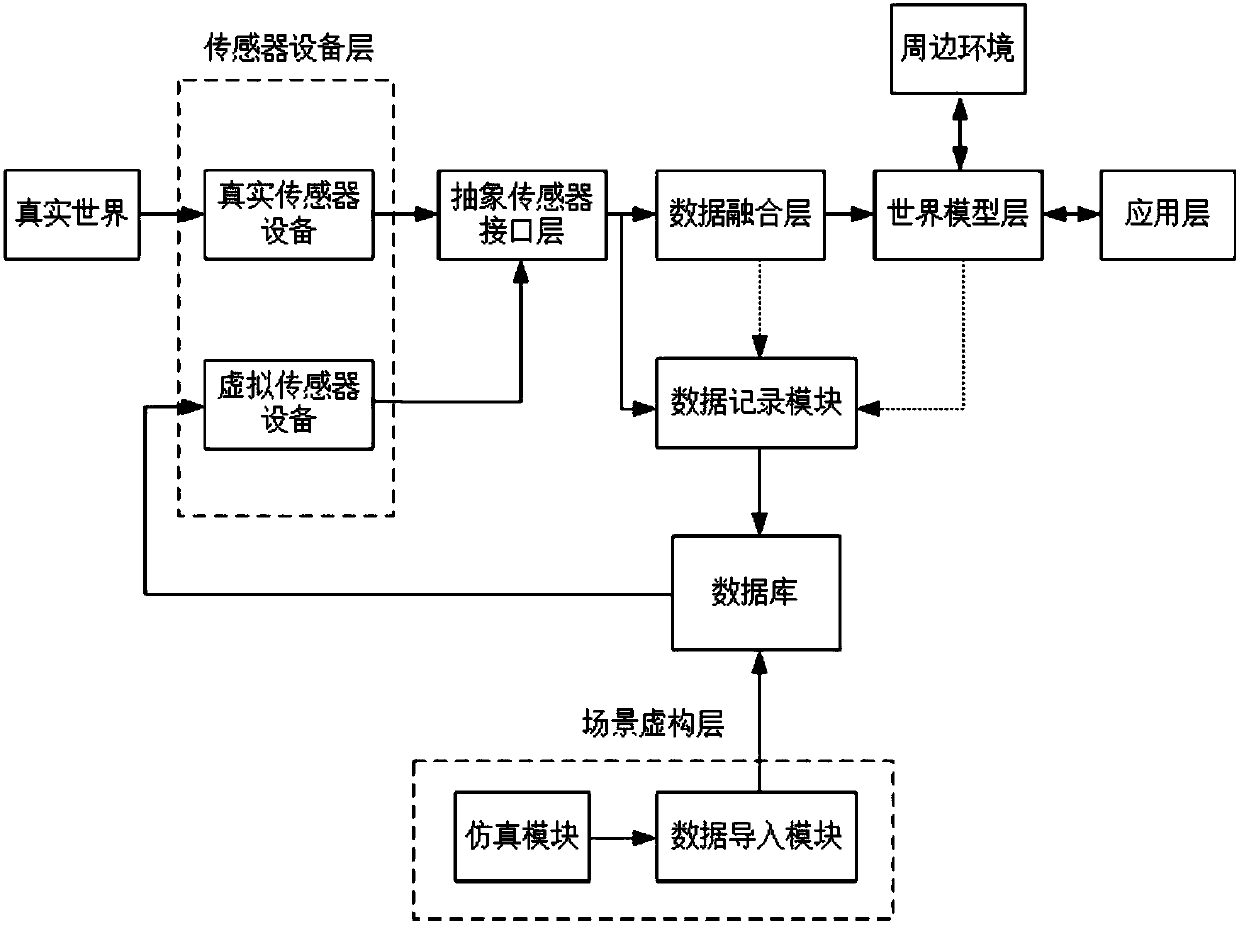

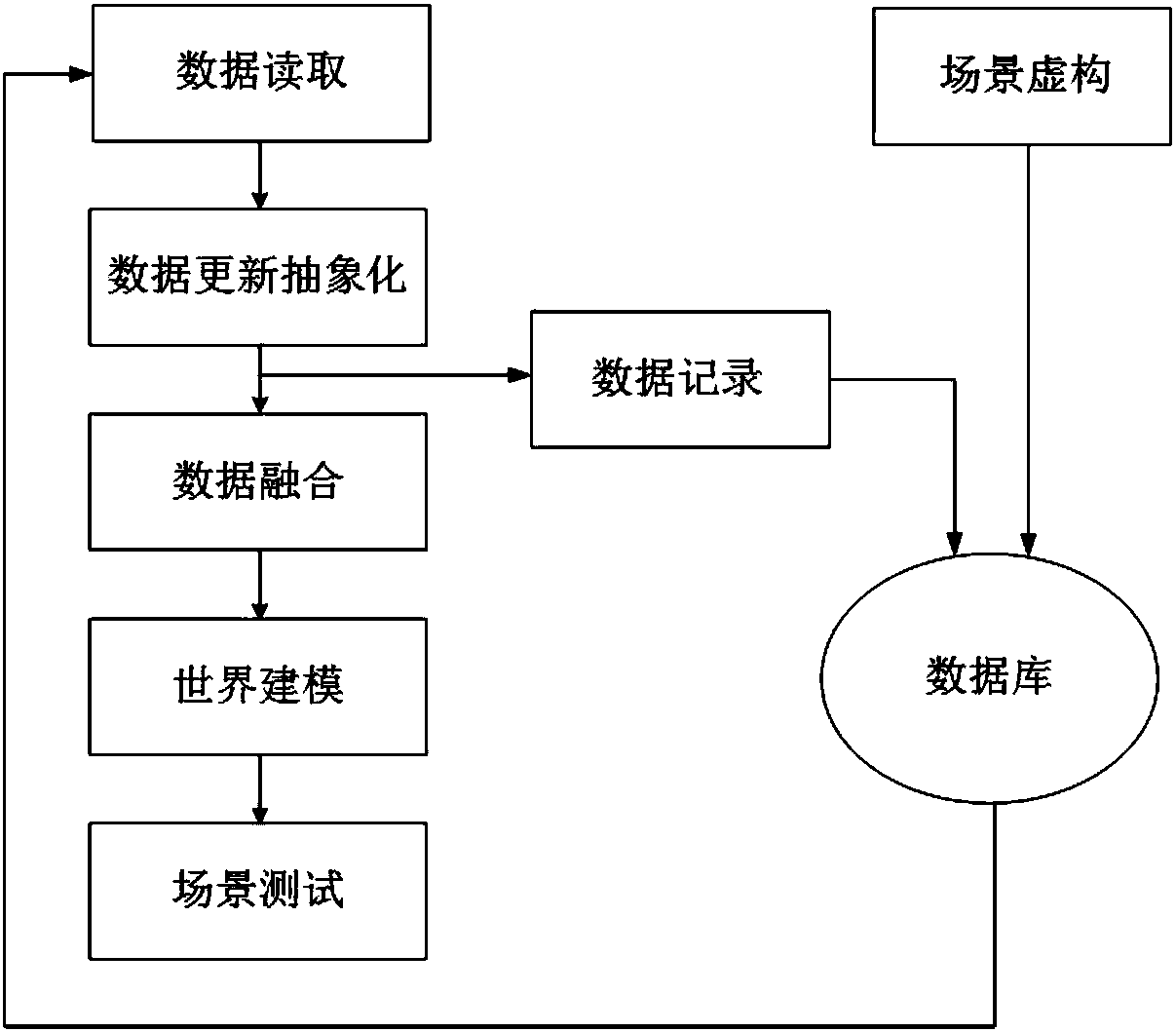

Virtuality and reality combined internet of vehicles application scene test system and method

ActiveCN107944091AStrong device portabilityPortableSoftware testing/debuggingDesign optimisation/simulationProtocol ApplicationScenario testing

The invention relates to a virtuality and reality combined internet-of-vehicles application scene test system and method. The scene test system comprises a sensor equipment layer, an abstract sensor interface layer, a data fusion layer, a world model layer, an application layer, a database and a scene imagination layer, wherein the sensor equipment layer is used for obtaining and sending real scene data and virtual scene data; the abstract sensor interface layer is used for separating the data fusion layer, the application layer ad the sensor equipment layer, and providing data reading interfaces for the data fusion layer, the world model layer and the application layers after the separation; the data fusion layer is connected with the abstract sensor interface layer and is used for collecting and integrating the acquired scene data; the world model layer is used for receiving the integrated scene data so as to construct a world model; the application layer is used for carrying out scene test in the world model; the database is used for storing the data; and the scene imagination layer is sued for constructing virtual scenes and importing virtual scene data into the database. Compared with the prior art, the system and method have the advantages that virtuality and reality combined scene test can be realized, the equipment transportability is strong, the scenes can be played back and the test is simple, convenient and efficient.

Owner:TONGJI UNIV

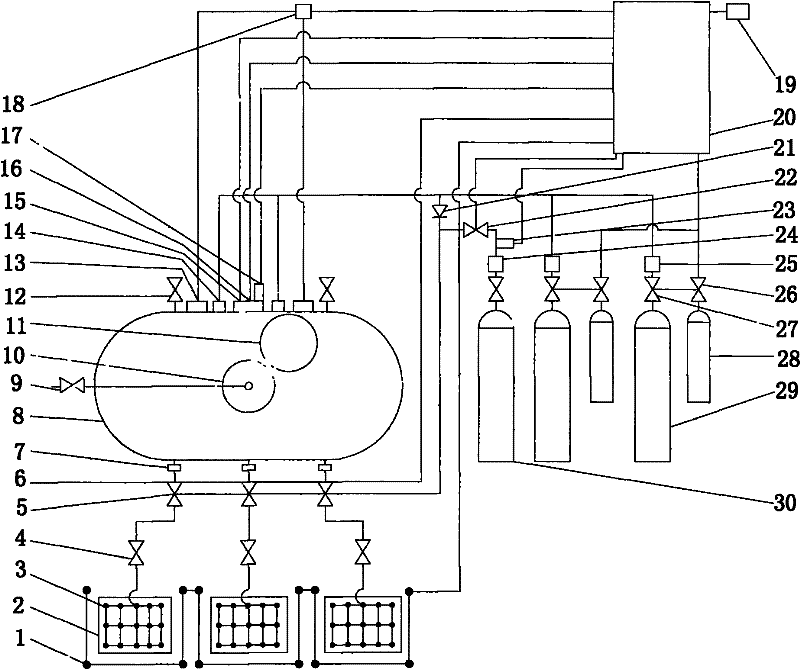

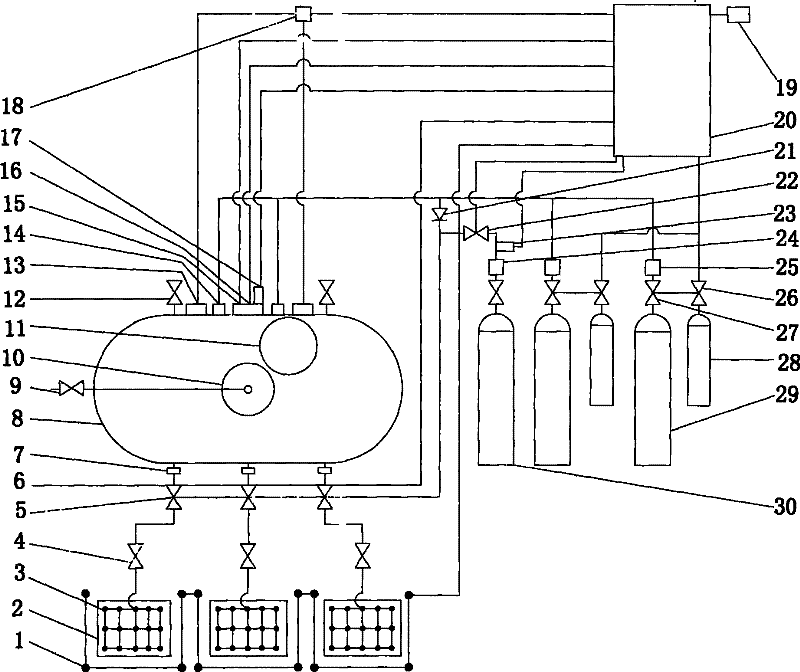

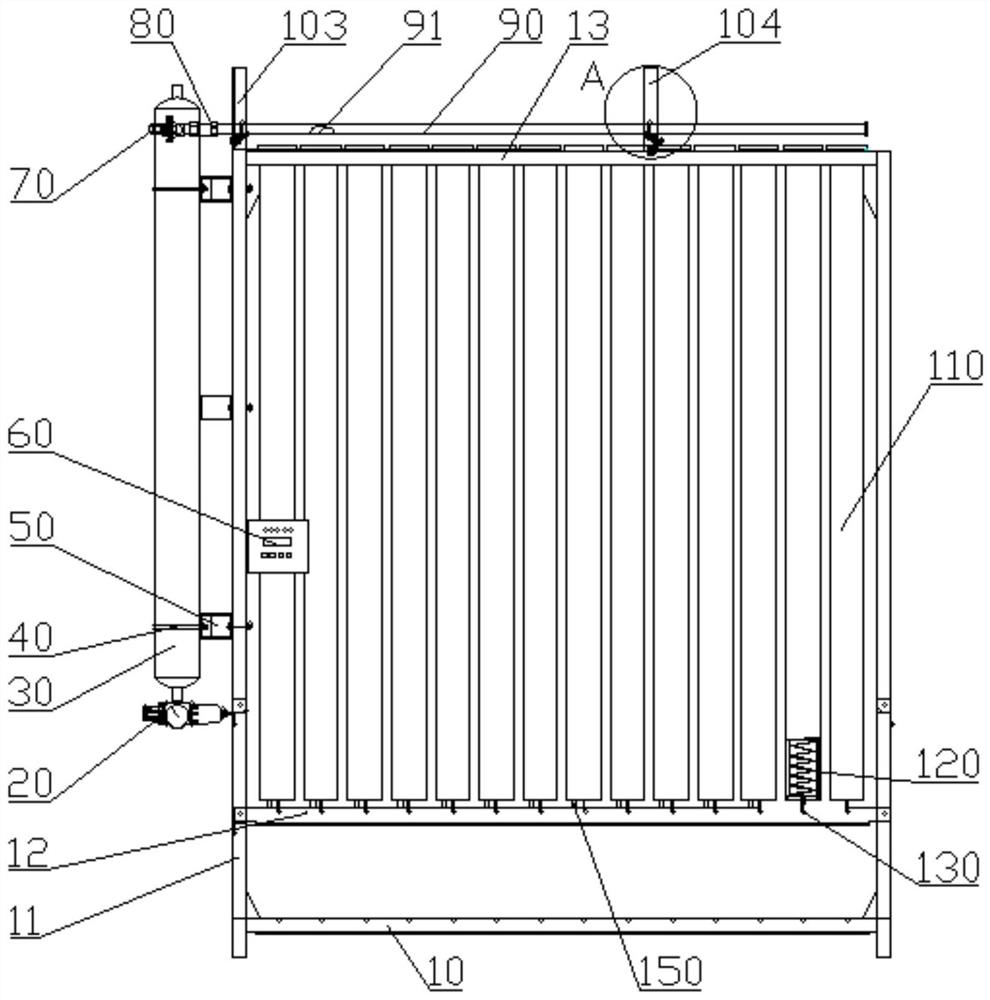

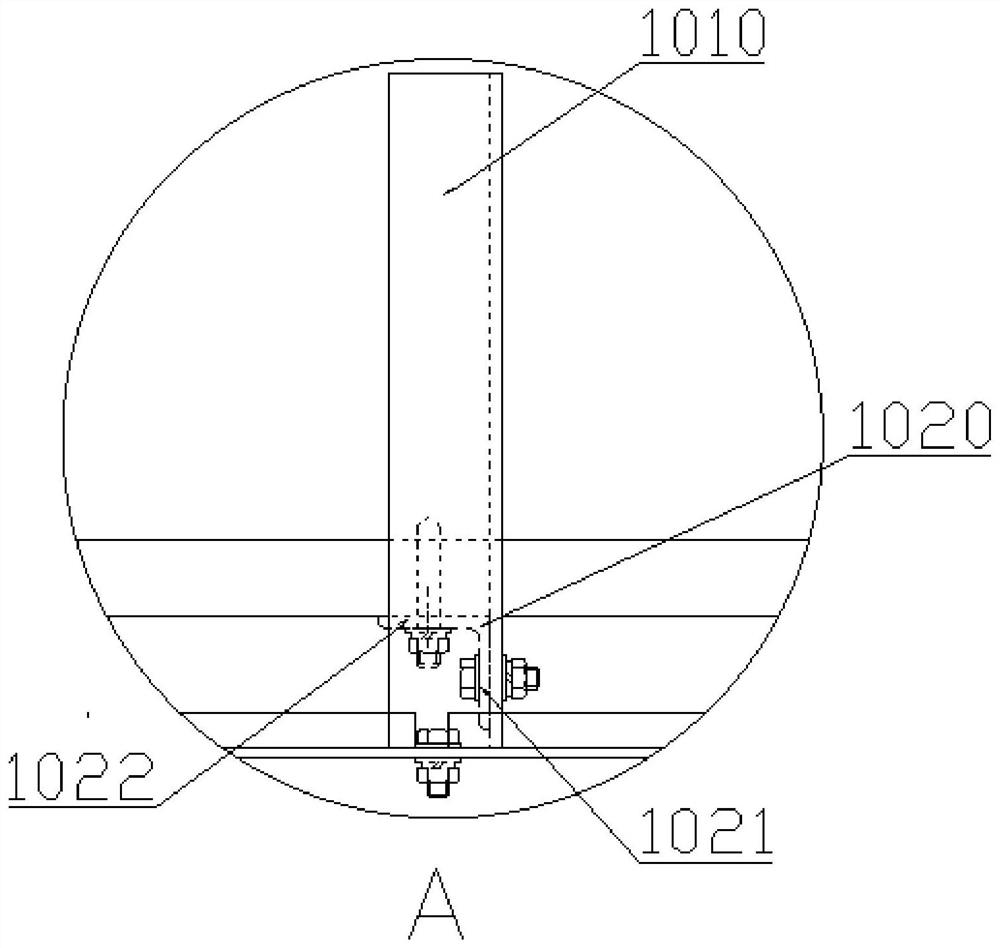

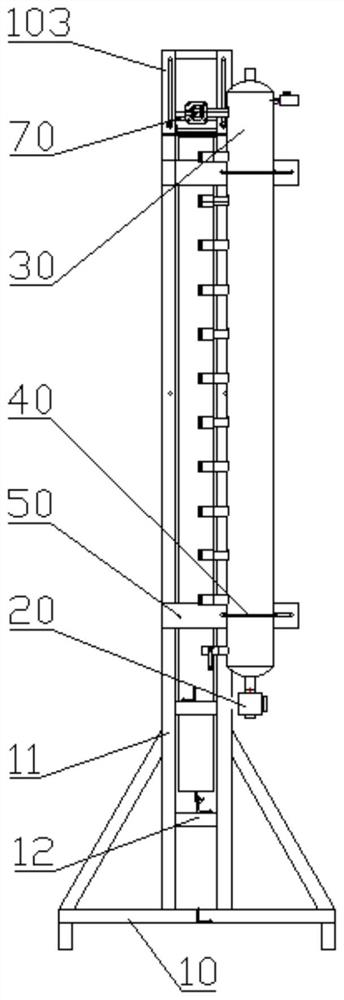

Intelligent approach automatic fire extinguishing system

ActiveCN101797426AEfficient and convenient testingGuaranteed uptimeFire rescueFire alarmsCollection systemEngineering

The invention relates to an intelligent approach automatic fire extinguishing system, which comprises a fire fighting agent storage tank combination system, an approach atomizer combination fire fighting system, an intelligent fire fighting control system and a fire monitor system. The intelligent fire fighting control system comprises a fire information collecting system, a central control system and a fire fighting device control system. The fire information collecting system collects fire field information and transmits to the central control system andor receives manual order and transmits the order to the fire fighting device control system. The central control system receives the information transmitted by the fire information collecting system andor the fire fighting device control system, automatically generates the order or receives the manual input order and transmits the order to the fire fighting device control system. The fire fighting device control system receives the order transmitted by the fire information collecting system andor the central control system and adjusts the running state of the fire fighting agent storage tank combination system and the approach atomizer combination fire fighting system. The system is safe, reliable, high efficient, economical and environment-friendly and can be extensively applied to various fields.

Owner:苏州赛夫特消防科技有限公司

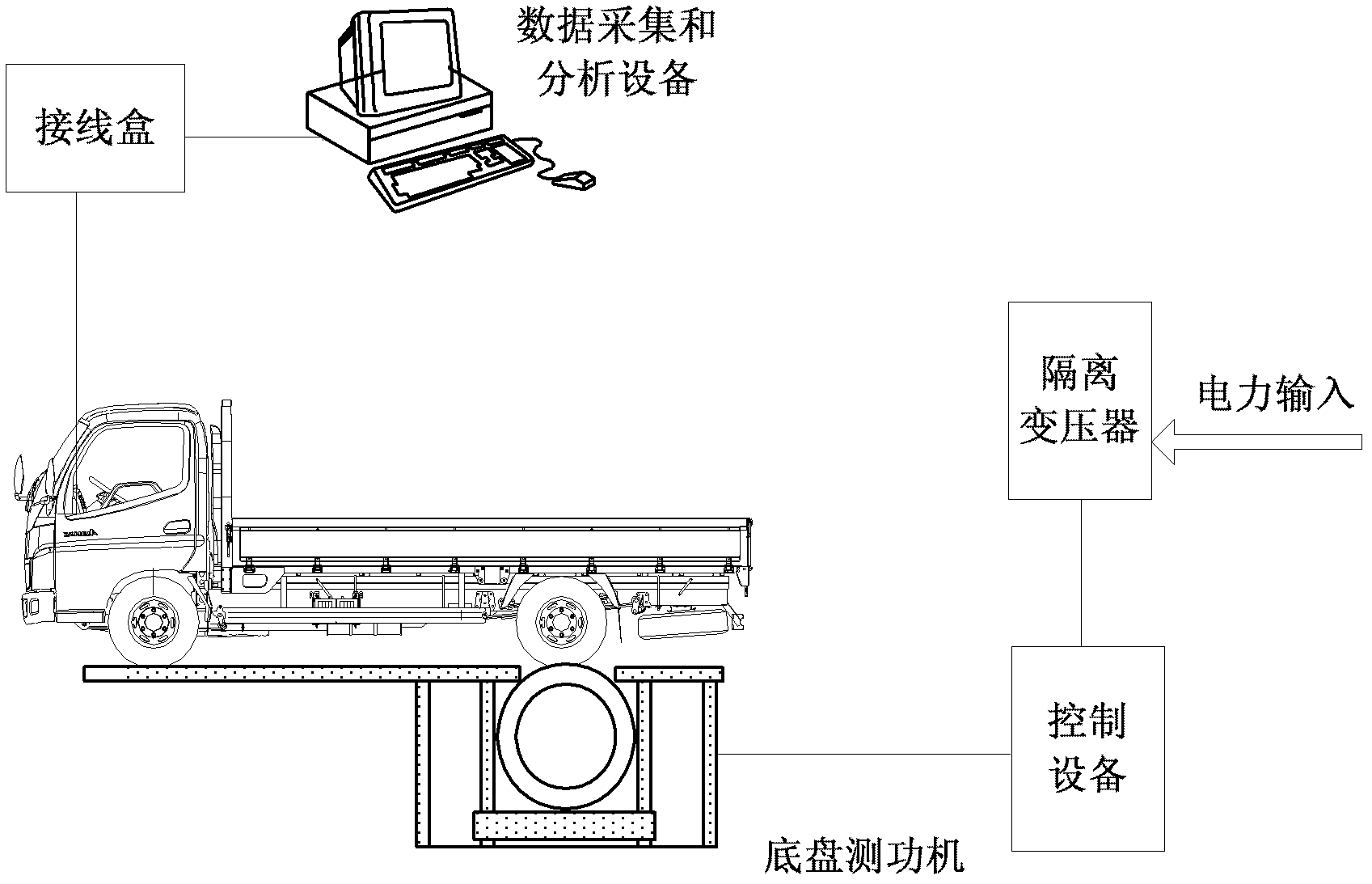

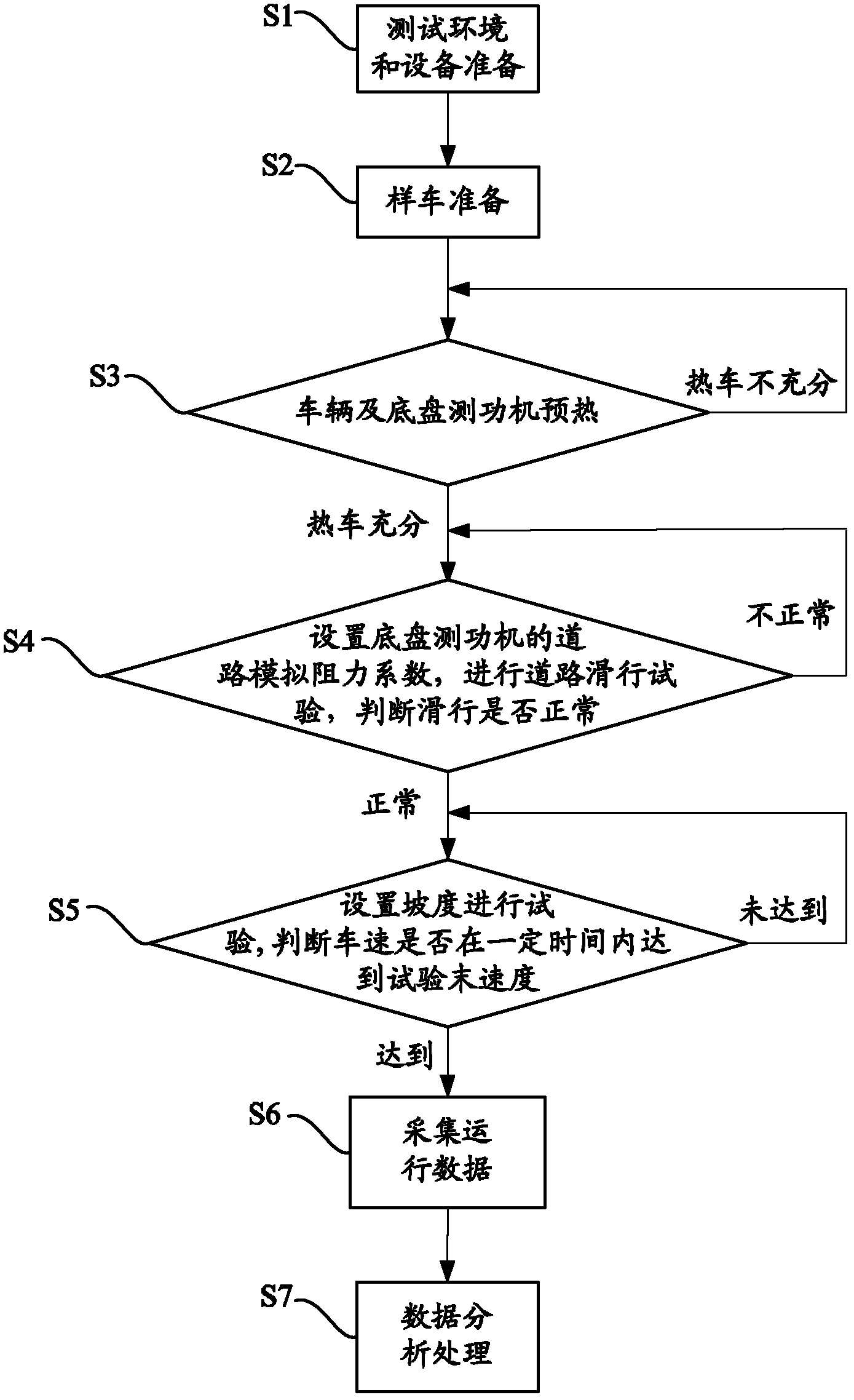

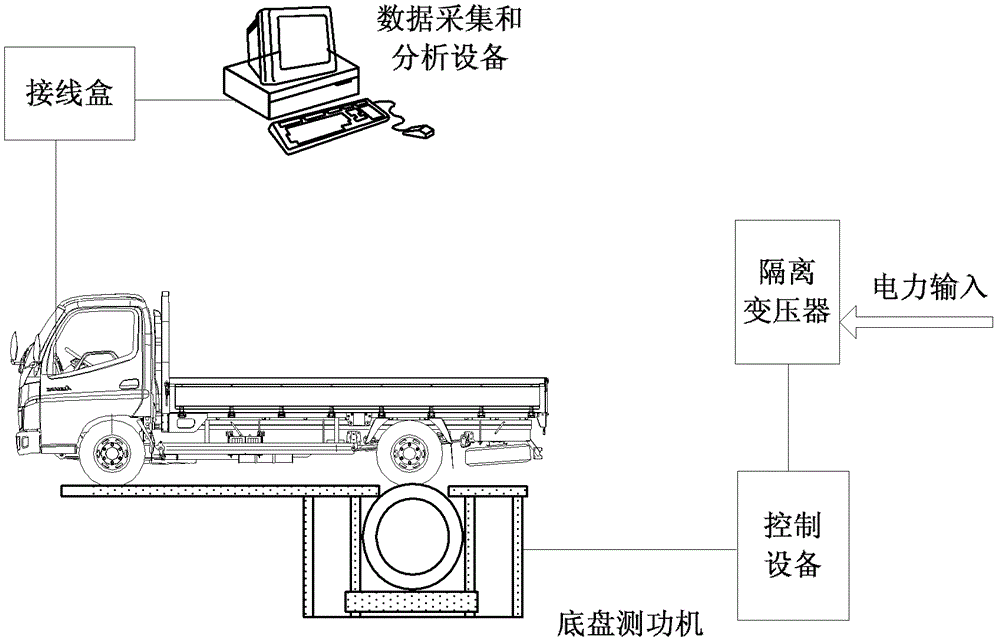

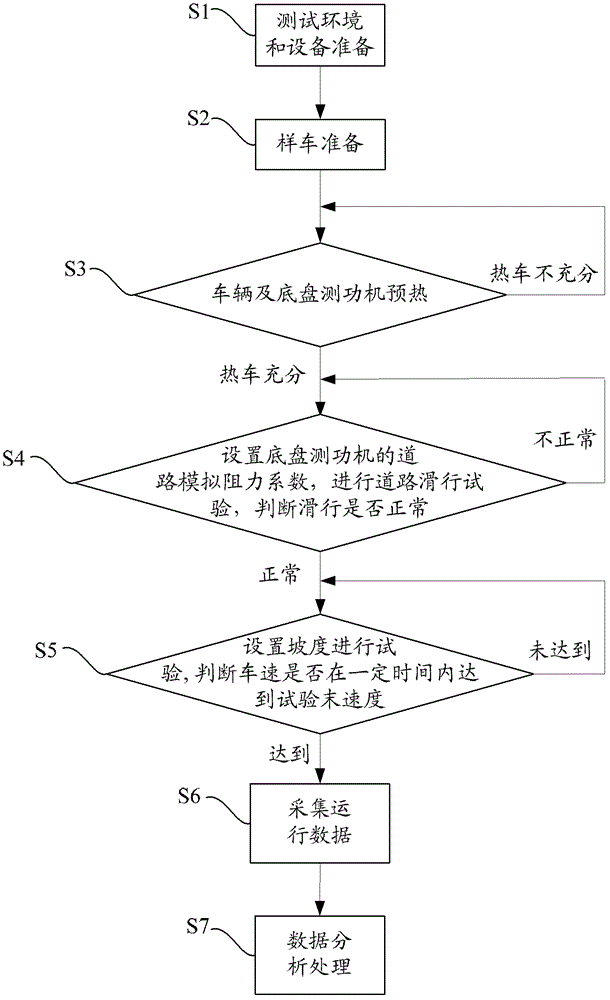

System and method for indoor exhaust braking test of vehicle engine

ActiveCN103134683AHigh precisionSimplify the collection processEngine testingData needsRolling chassis

The invention discloses a system and a method for an indoor exhaust braking test of a vehicle engine. The system comprises a chassis dynamometer, a data collecting device and a data analysis device. A drum of the chassis dynamometer is arranged below driving wheels of a tested vehicle, the road simulation resistance coefficient of a slope with preset angles is arranged in the chassis dynamometer, and so that the road simulation resistance of the slope with the preset angles is exerted to the tested wheel. The data collecting device is used for collecting the operating data of the vehicle when the vehicle travels on the slope with a plurality of preset angles. The data analysis device is used for analyzing the performance of exhausting and braking of the vehicle according to the collected operating data. According to the system and the method for the indoor exhaust braking test of the vehicle engine, the exhaust braking performance of the vehicle is tested by the chassis dynamometer, the data needed in a test is collected, the process of data collecting is simple, convenient and fast, and the precision of the collected data is high. Testing is convenient, fast and effective, and the cost of testing is greatly lowered.

Owner:BEIQI FOTON MOTOR CO LTD

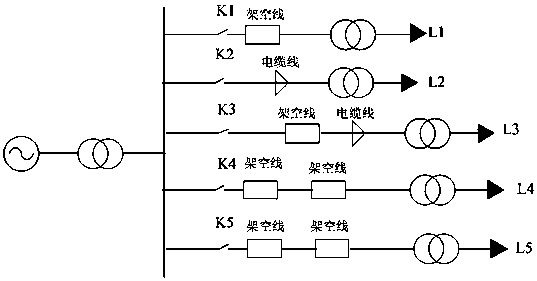

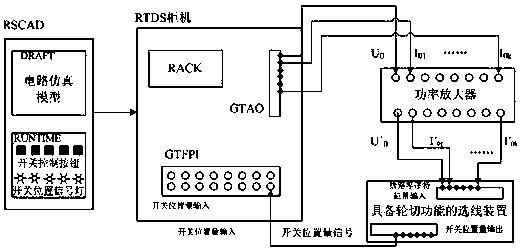

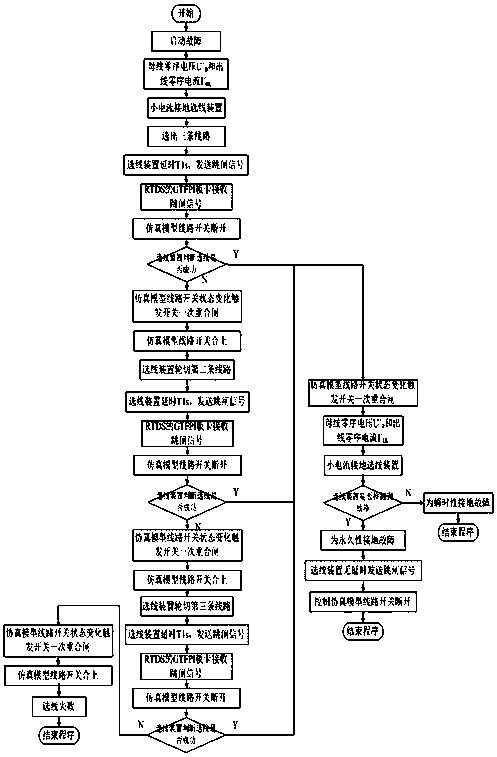

Alternate switching function testing method for small-current fault line selection device

ActiveCN107783070AWith automatic reclosing functionImplement testElectrical measurementsAutomatic controlAudio power amplifier

The invention discloses an alternate switching function testing method for a small-current fault line selection device. A power system real-time digital simulator, a power amplifier and the small-current fault line selection device with an alternate switching function. An RTDS real-time simulator generates a grounding signal, and amplifies the grounding signal through the power amplifier to the small-current fault line selection device with the alternate switching function; the small-current fault line selection device with the alternate switching function receives the amplified signal and analyzes the signal, N lines with a larger probability are selected for alternate switching, and then a tripping signal is fed back to a GTFPI board card of the power system real-time digital simulator;a tripping operation is carried out on the selected lines by controlling a corresponding outgoing line switch action in a line simulation model, and the small-current fault line selection device withthe alternate switching function judges whether line selection is correct or not according to a tripping result of an outgoing line switch. The whole testing process is automatically controlled and executed by RSCAD software, so that automatic control over the testing process is achieved.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

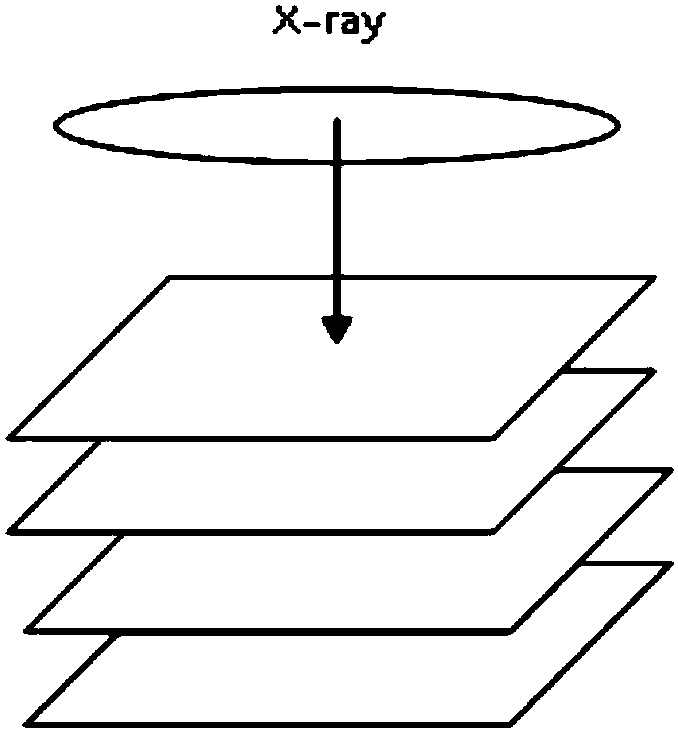

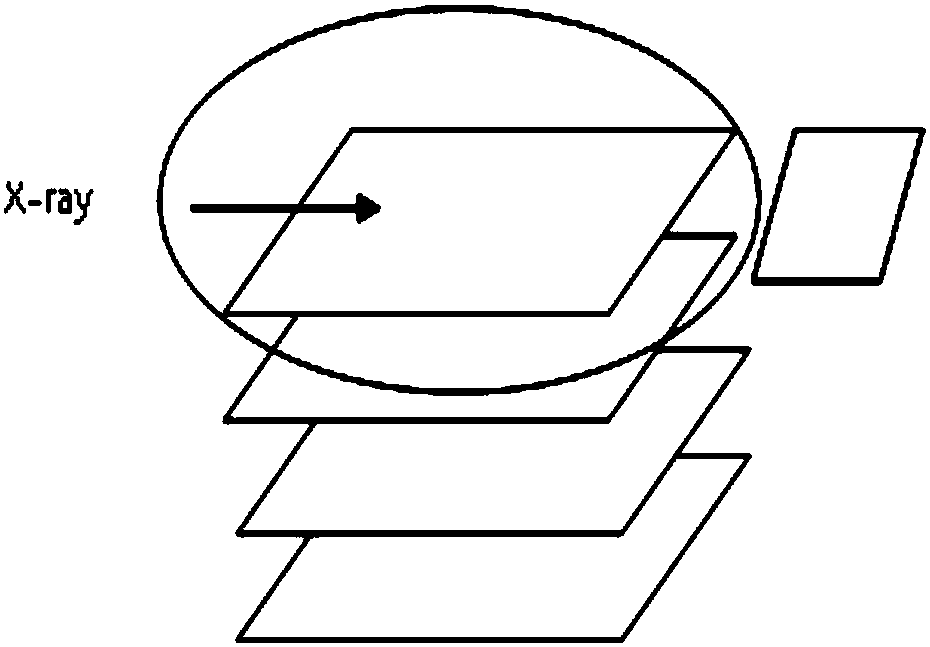

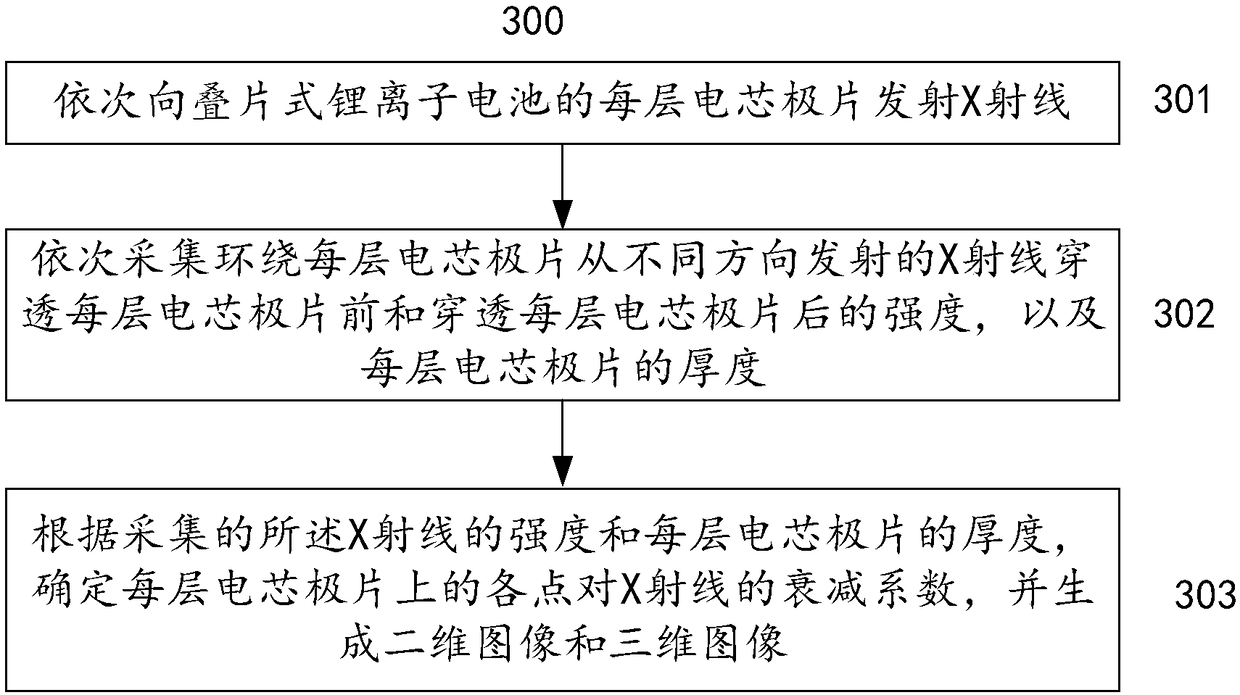

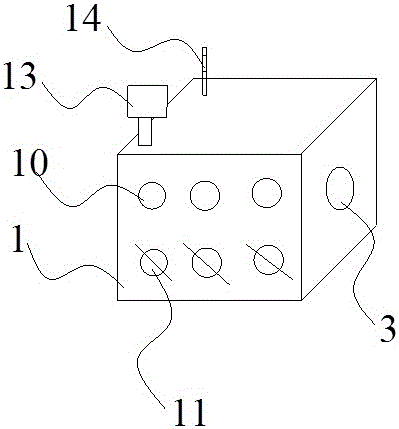

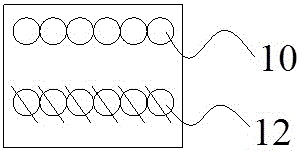

Method and system for nondestructively detecting laminated lithium ion battery

InactiveCN108387594AHigh density resolutionEfficient and convenient testingMaterial analysis using wave/particle radiationAttenuation coefficientX-ray

The invention provides a method and a system for nondestructively detecting a laminated lithium ion battery. The method comprises the following steps: sequentially emitting X-rays to every layer of cell electrode sheets of the laminated lithium ion battery, wherein the incident direction of the X-rays is parallel to the every layer of cell electrode sheets of the battery to be detected, and the X-rays scan around the cell electrode sheets in different directions; sequentially acquiring the intensities of the X-rays emitted from different directions and encircling the every layer of cell electrode sheets before and after penetrating the every layer of cell electrode sheets and the thickness of the every layer of cell electrode sheets; and determining the attenuation coefficient of the X-rays at each point on the every layer of cell electrode sheets according to the acquired intensity of the X-rays and the thickness of the every layer of the cell electrode sheets, and generating a two-dimensional image of the every layer of cell electrode sheets and a three-dimensional image of the laminated lithium ion battery. The method scans the cell electrode sheets of the laminated lithium ionbattery based on an X-ray tomography technology to realize the online monitoring of the state of the battery.

Owner:CHINA ELECTRIC POWER RES INST

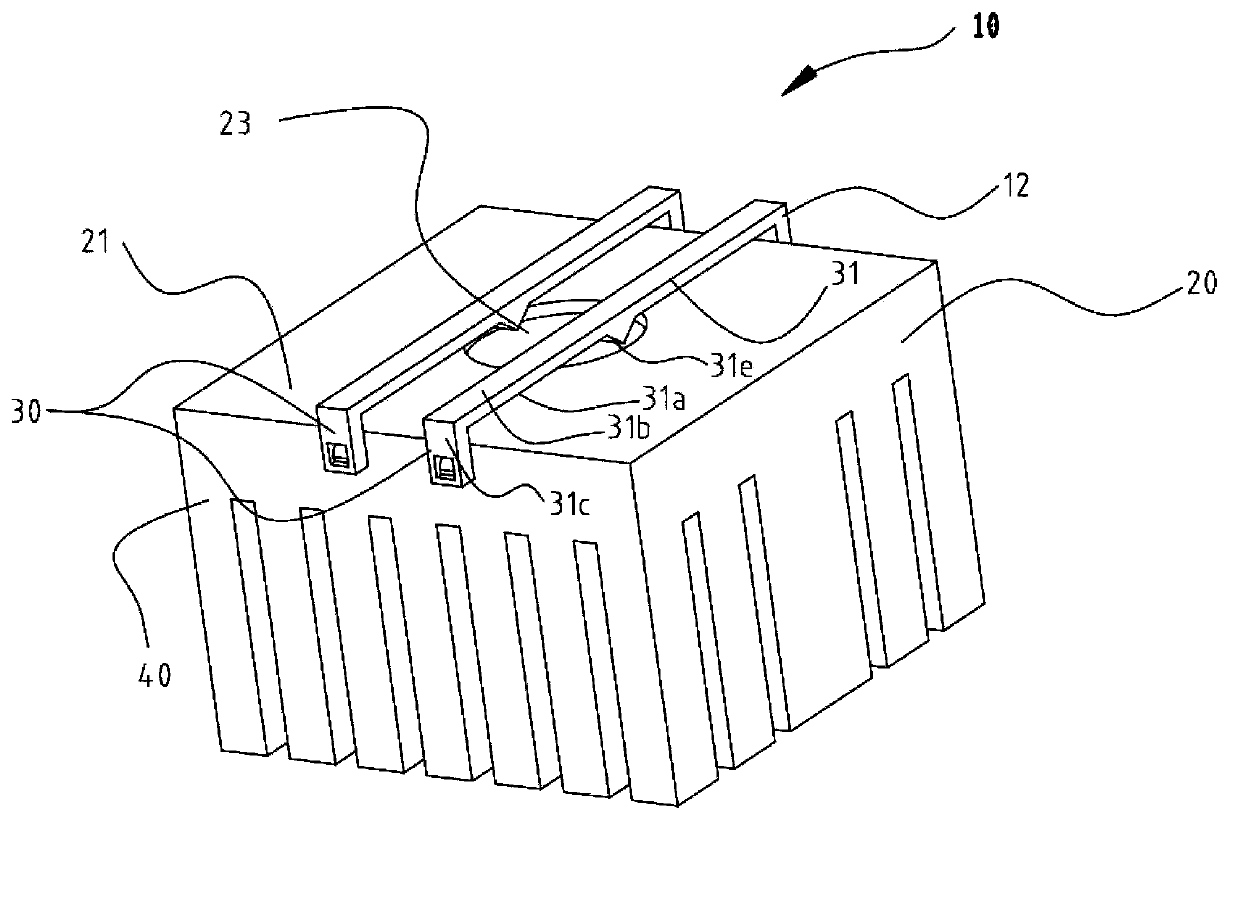

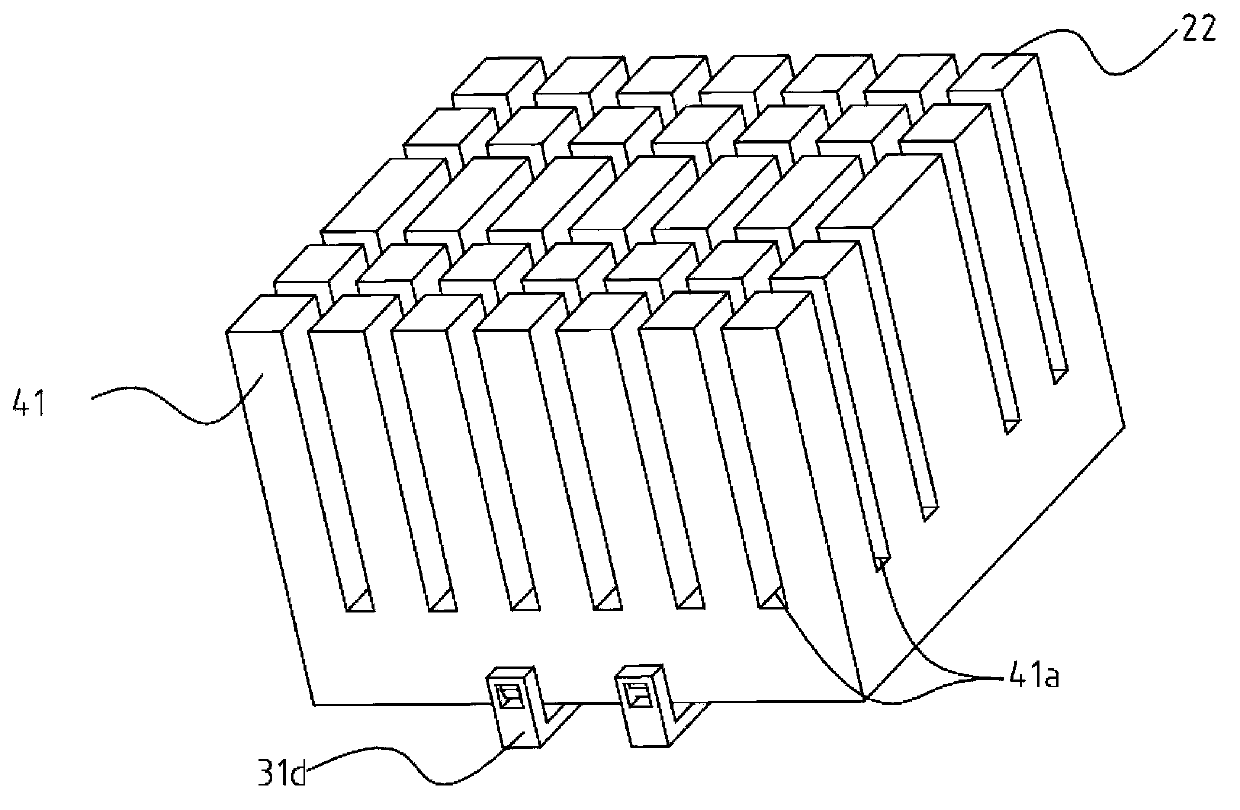

Radiating device and testing device with radiating device

InactiveCN103968344AEfficient and convenient testingPoint-like light sourceLighting heating/cooling arrangementsLight-emitting diodeTraining set

The invention discloses a radiating device used for an LED (light-emitting diode). The radiating device comprises a casing and a fixing structure for fixing the LED on the casing, wherein the casing is oppositely provided with a first end surface and a second end surface, a mounting groove for mounting the LED is formed in the first end surface, the fixing structure is mounted on the first end surface, a radiating structure for radiating the heat of the LED is formed on the second end surface, and the radiating structure consists of a plurality of radiating blocks which are uniformly distributed on the second end surface at radial intervals. The radiating device is used for guiding the heat produced by the LED, so that the heat on the LED can be uniformly distributed on the radiating device. The invention further provides a testing device with the radiating device.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

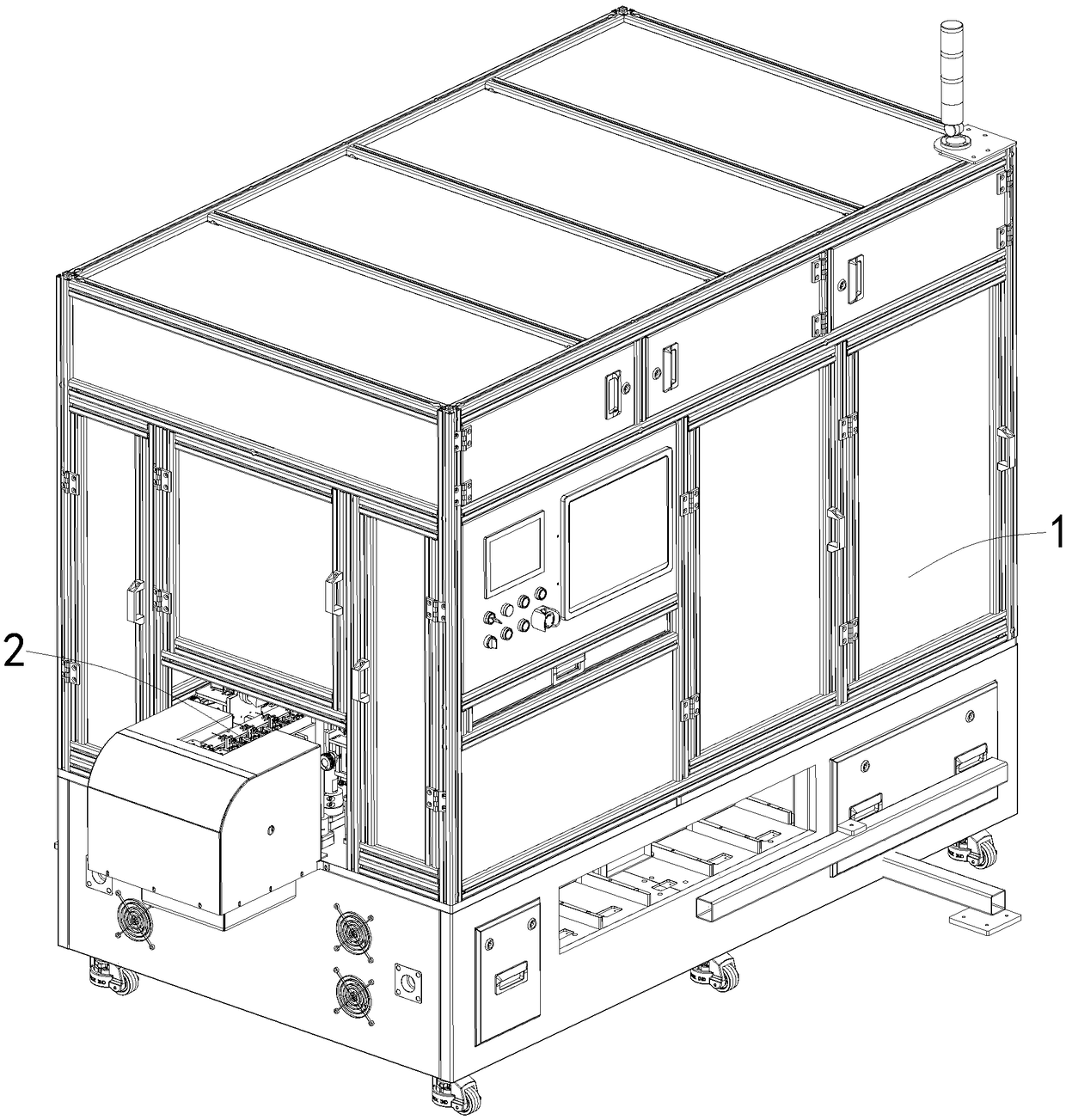

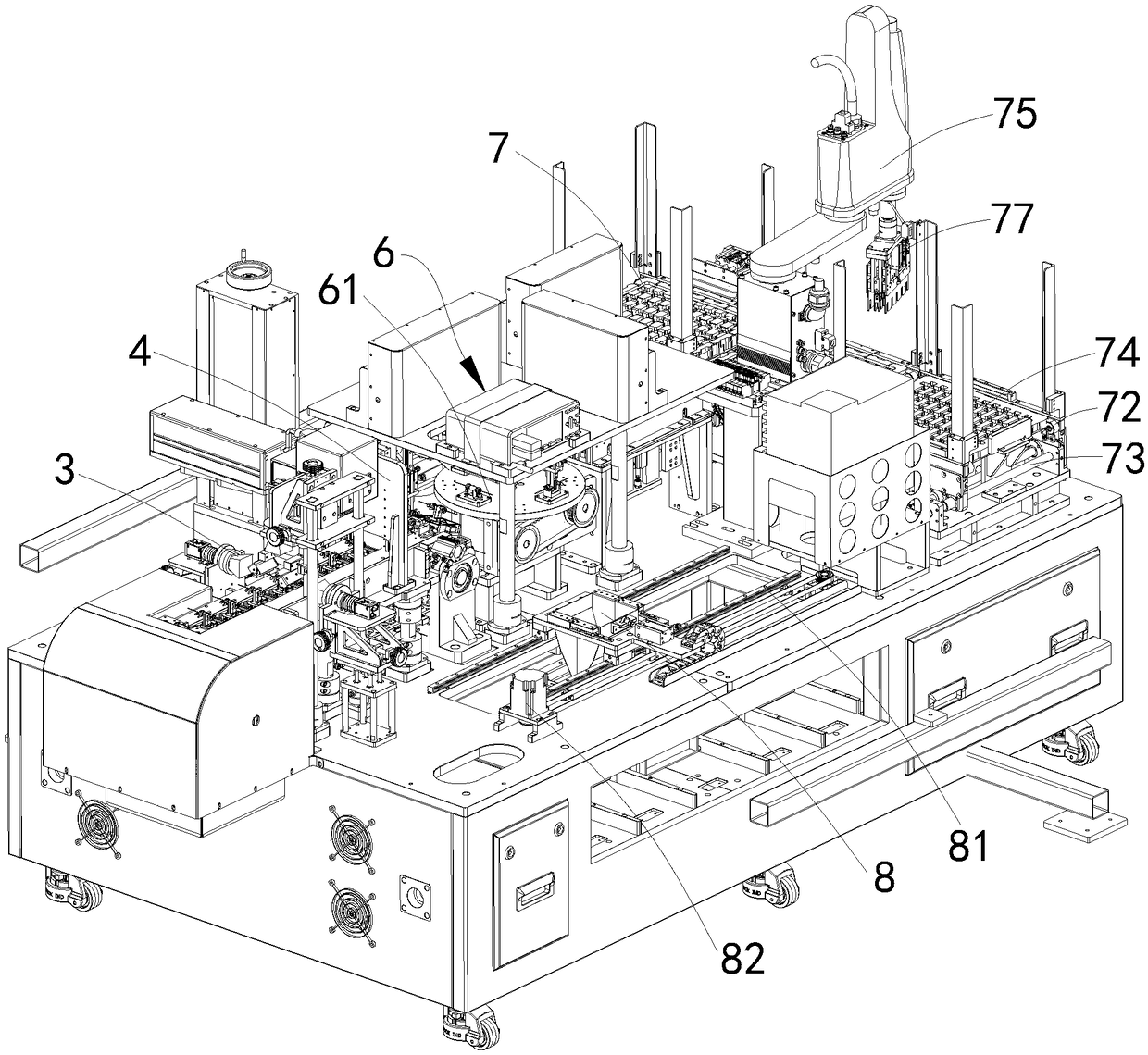

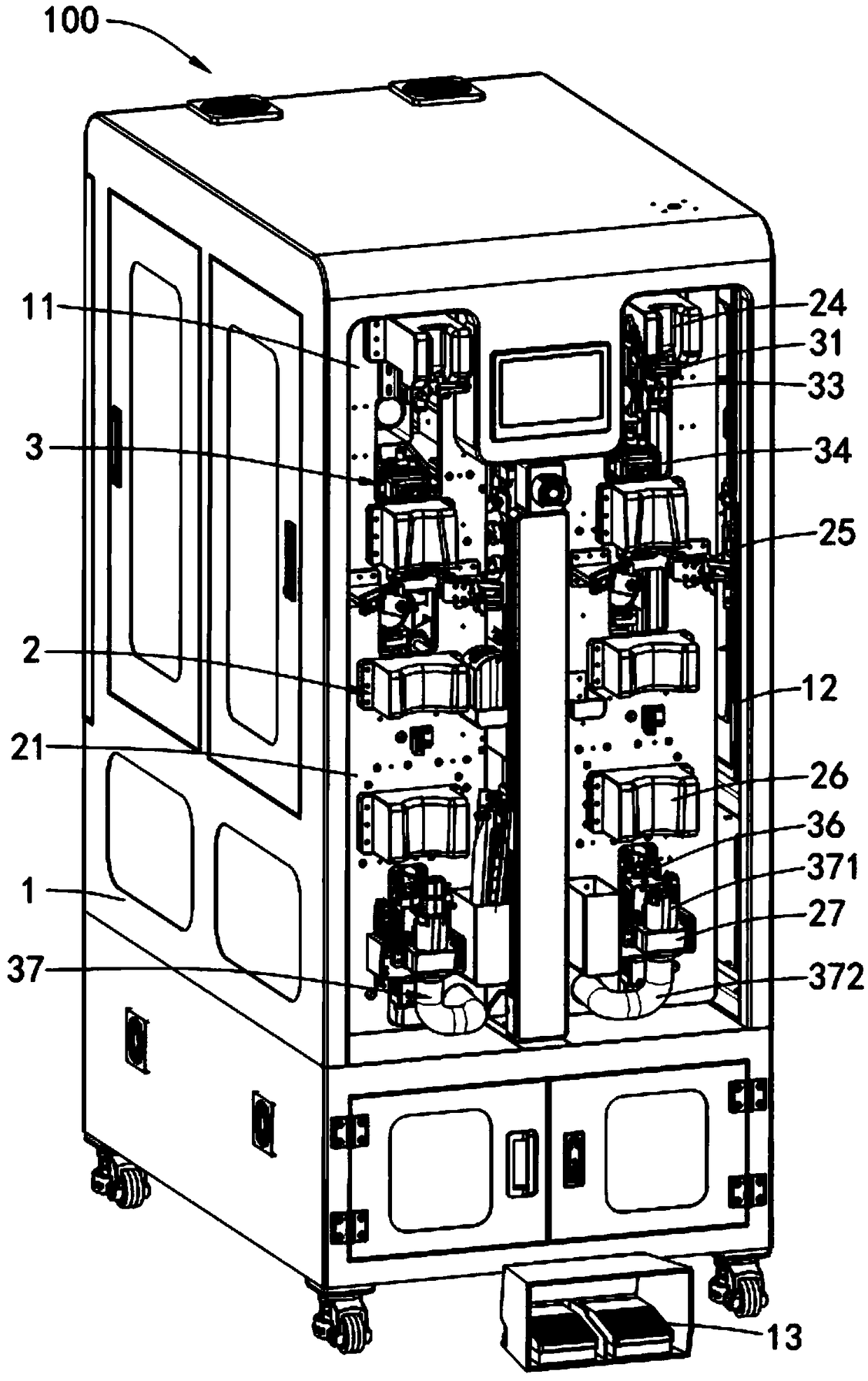

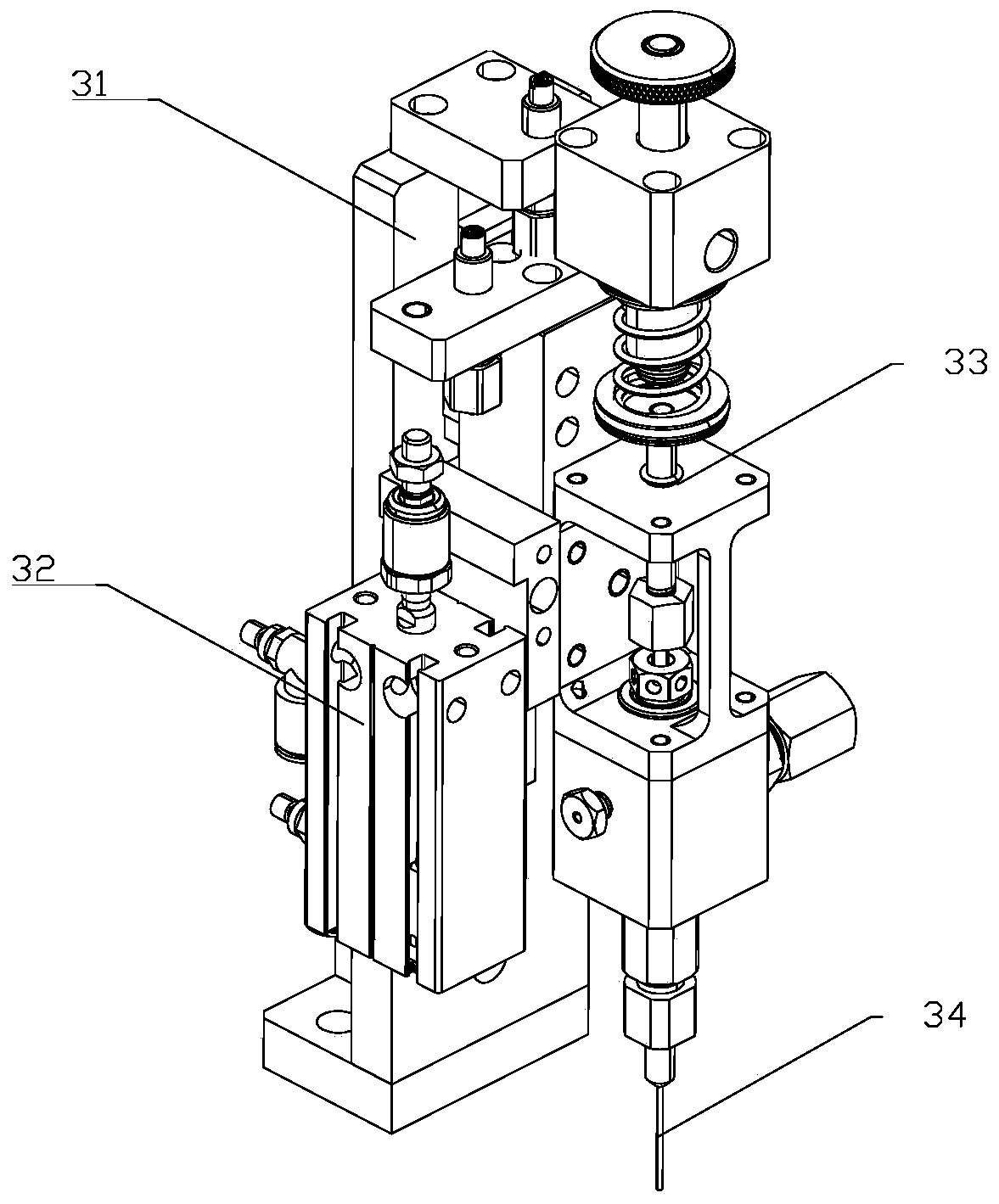

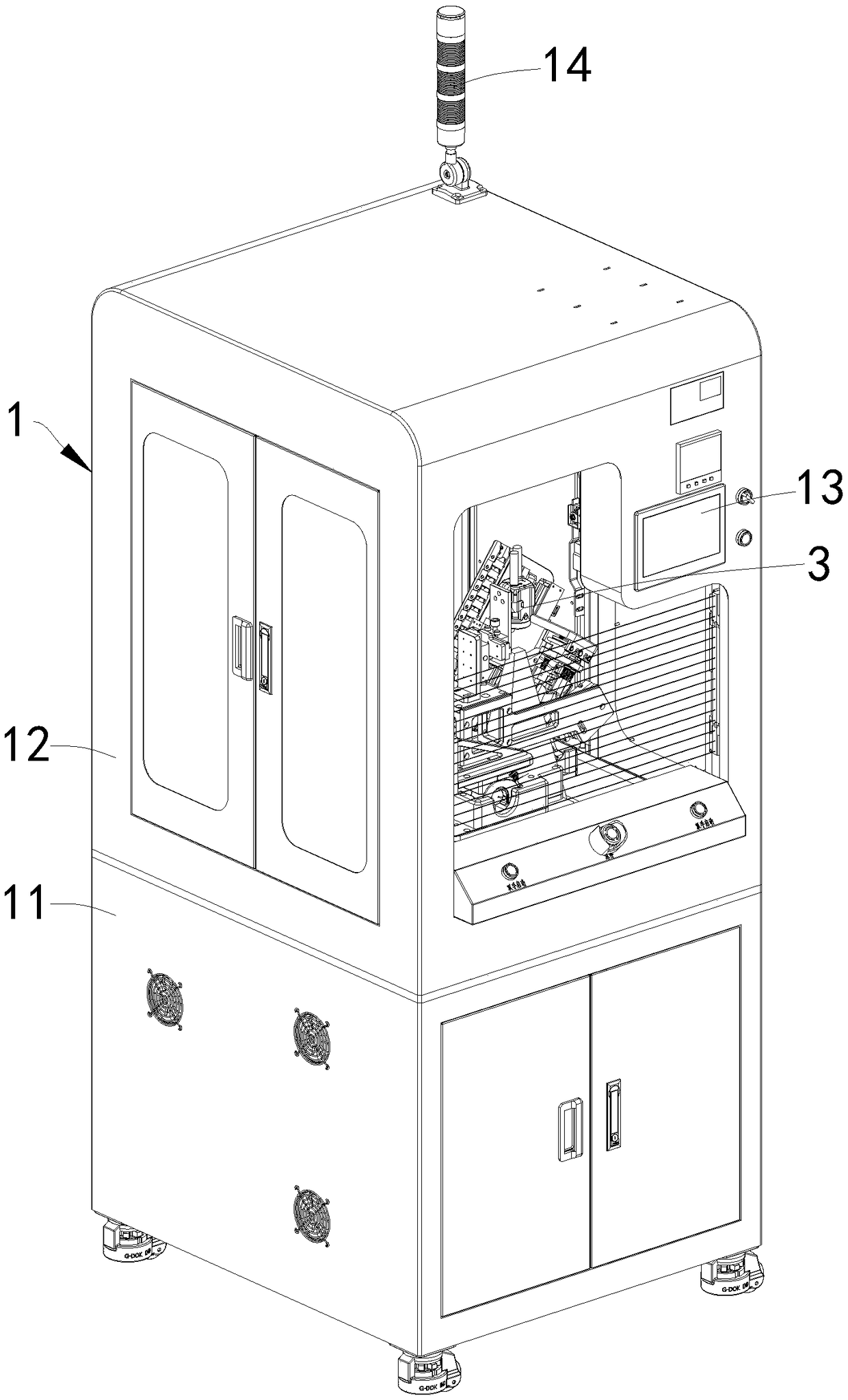

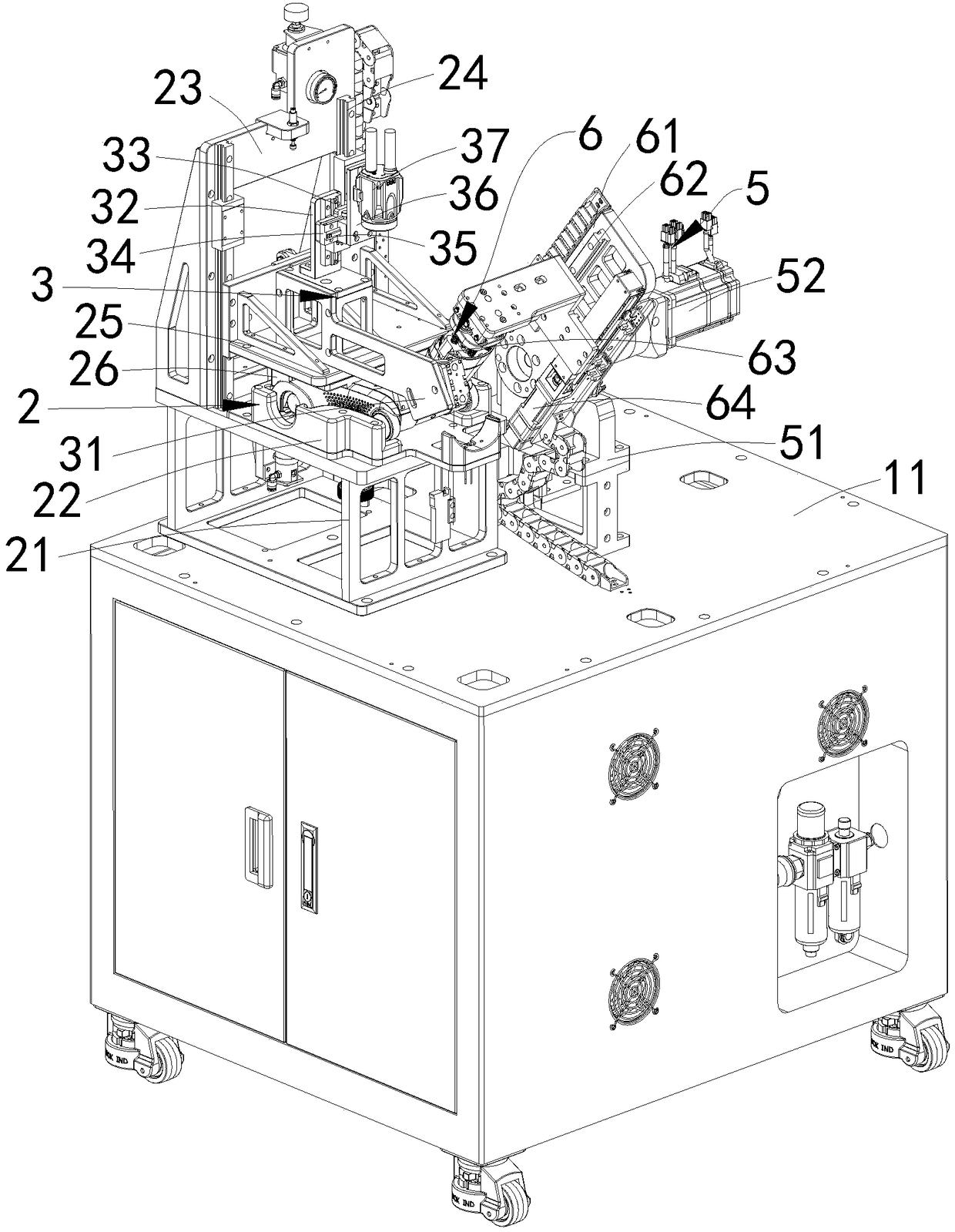

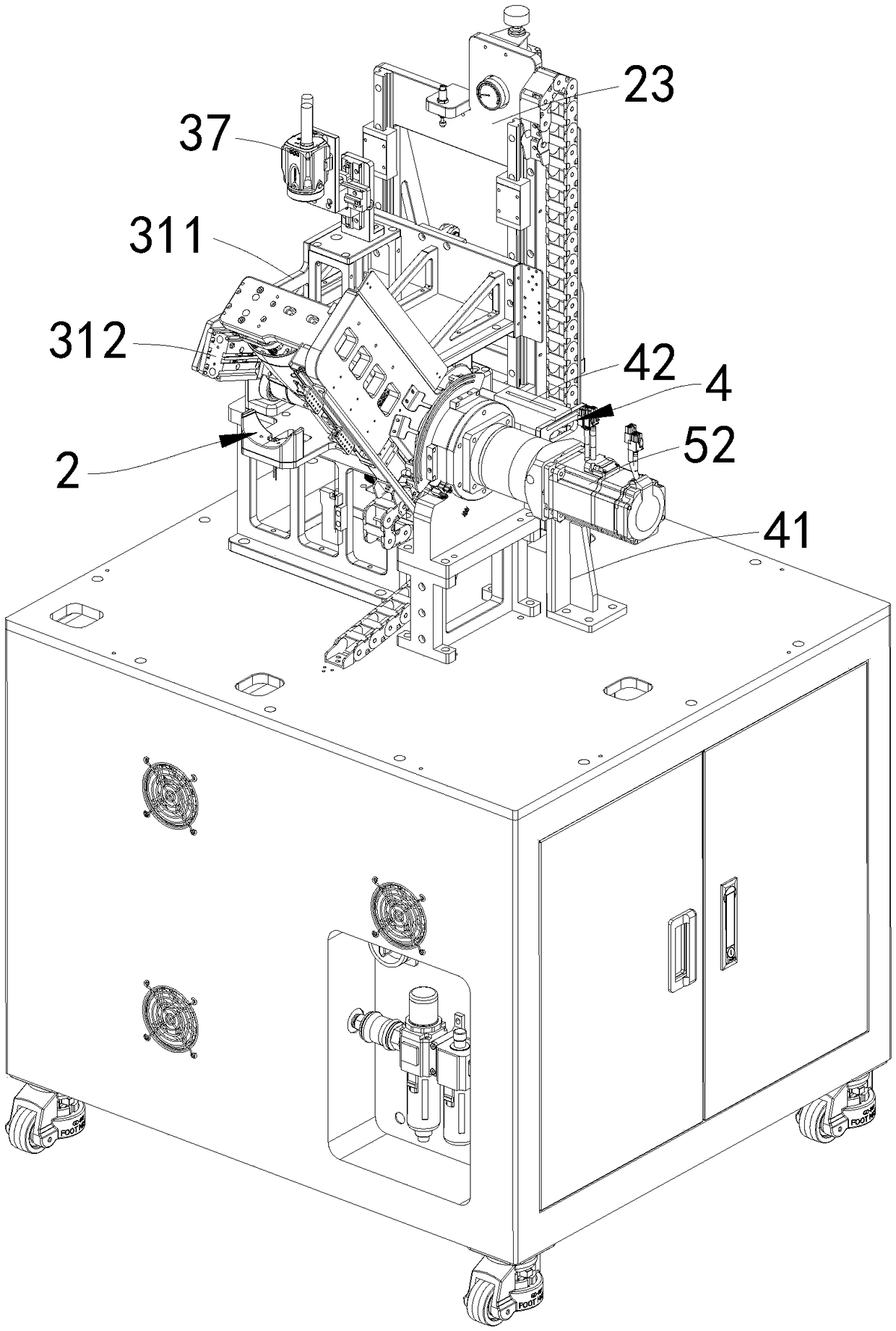

Fuse testing equipment

PendingCN108971013ARealize intelligent testingEfficient and convenient testingFuse device manufactureSortingLaser detectionOn resistance

The invention provides fuse testing equipment. The equipment comprises a rack, a transmission mechanism arranged on the rack and a pin and appearance detection mechanism, a resistance detection mechanism, a laser mechanism, a laser detection mechanism and a qualified product blanking mechanism which are arranged in a transmission direction of the transmission mechanism in sequence, wherein an unqualified product box unit is arranged on the outer side of the laser mechanism. The transmission mechanism transmits fuses forwards, the pin and appearance detection mechanism detects whether or not pin angles of the fuses are correct, whether or not each two pins are in parallel and whether or not appearance dimensions are in set ranges, the resistance detection mechanism conducts testing on resistance, the laser mechanism conducts laser marking on an end cover of one end of each fuse, then the laser detection mechanism detects marking, the qualified fuses are subjected to blanking of the qualified product blanking mechanism, while the unqualified fuses enter the unqualified product box unit. Fuse pin and appearance detection, laser marking and marking detection are automatically conducted, intelligent testing of the fuses is achieved, testing is convenient and efficient, and manpower is saved.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

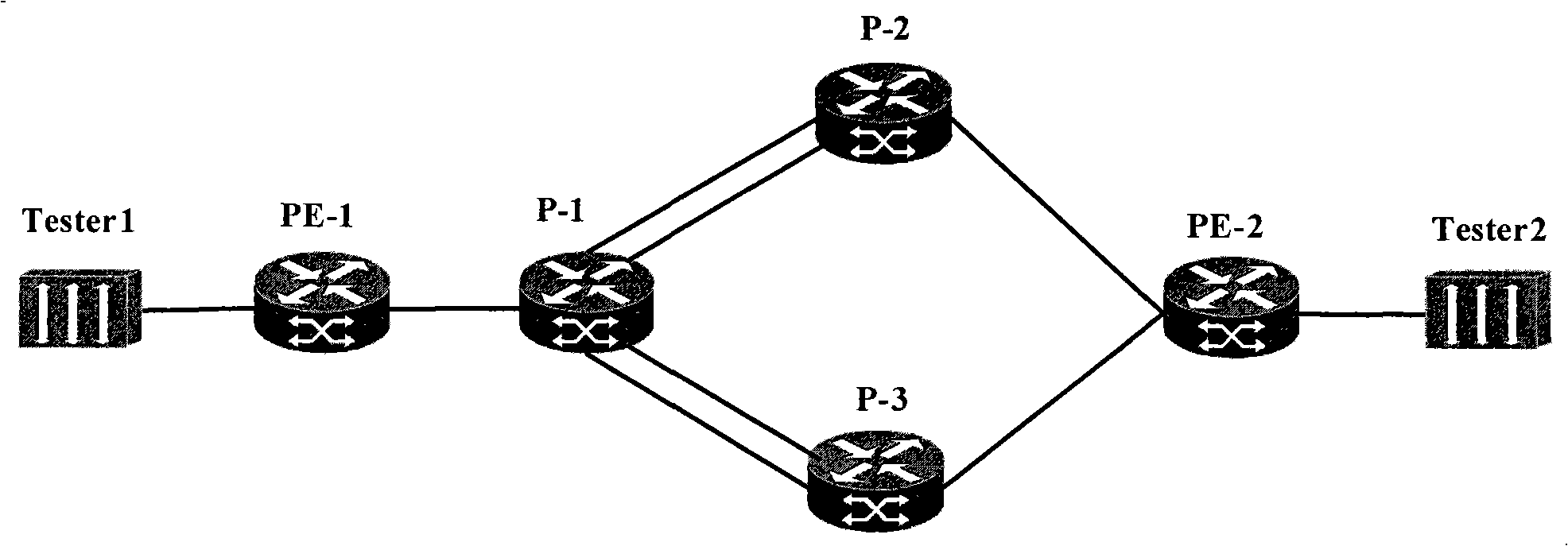

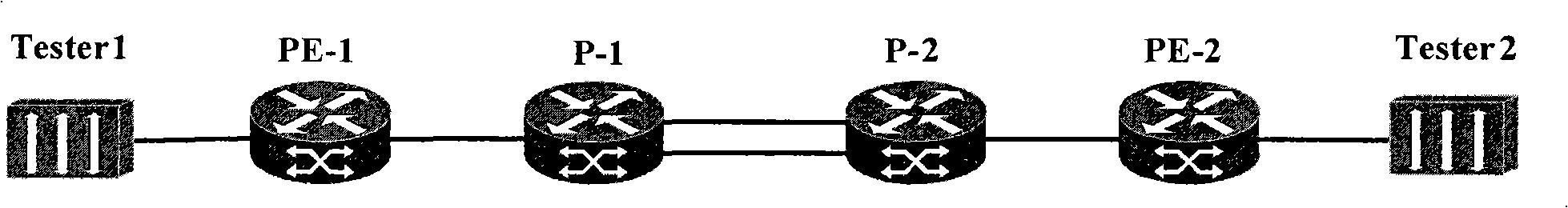

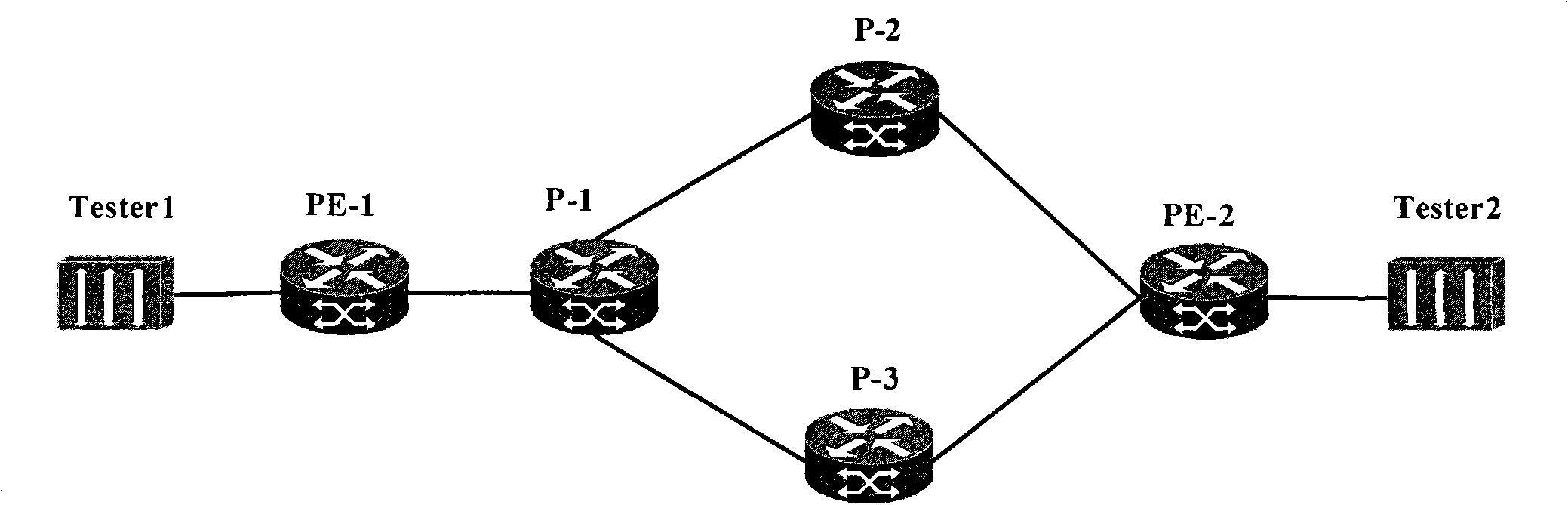

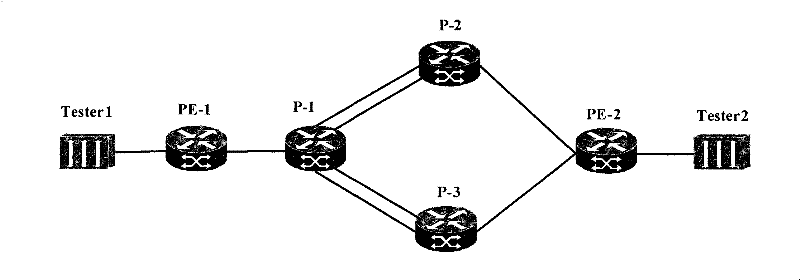

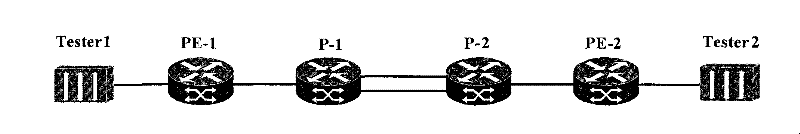

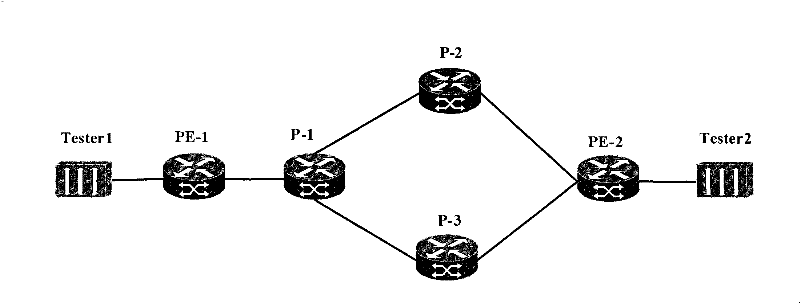

Test method for obtaining load factors of router and system thereof

The invention discloses a test method for obtaining load factors of a router in a BGP / MPLS VPN environment and a system thereof. The test method comprises the following steps: connecting a test instrument with a PE router in an MPLS / IP network; sending at least two test streams to the tested router by the test instrument, wherein, values of test parameters to be tested in each test stream are different, and other parameters are fixed; and recording link sharing condition in the stream output direction of the tested router, if traffic of the test stream can load sharing, judging the tested router can take the test parameters as the load factors for participating in load sharing calculation. By adopting the test method, the load factors on which the router performs VPN traffic load sharing can be conveniently and efficiently tested, and the effect for starting VPN traffic load sharing in a practical network traffic environment according to the obtained test results, which provides instruction opinions for deployment of the VPN traffic load sharing function of each equipment in a practical network, and the test results have greater reference value.

Owner:CHINA TELECOM CORP LTD

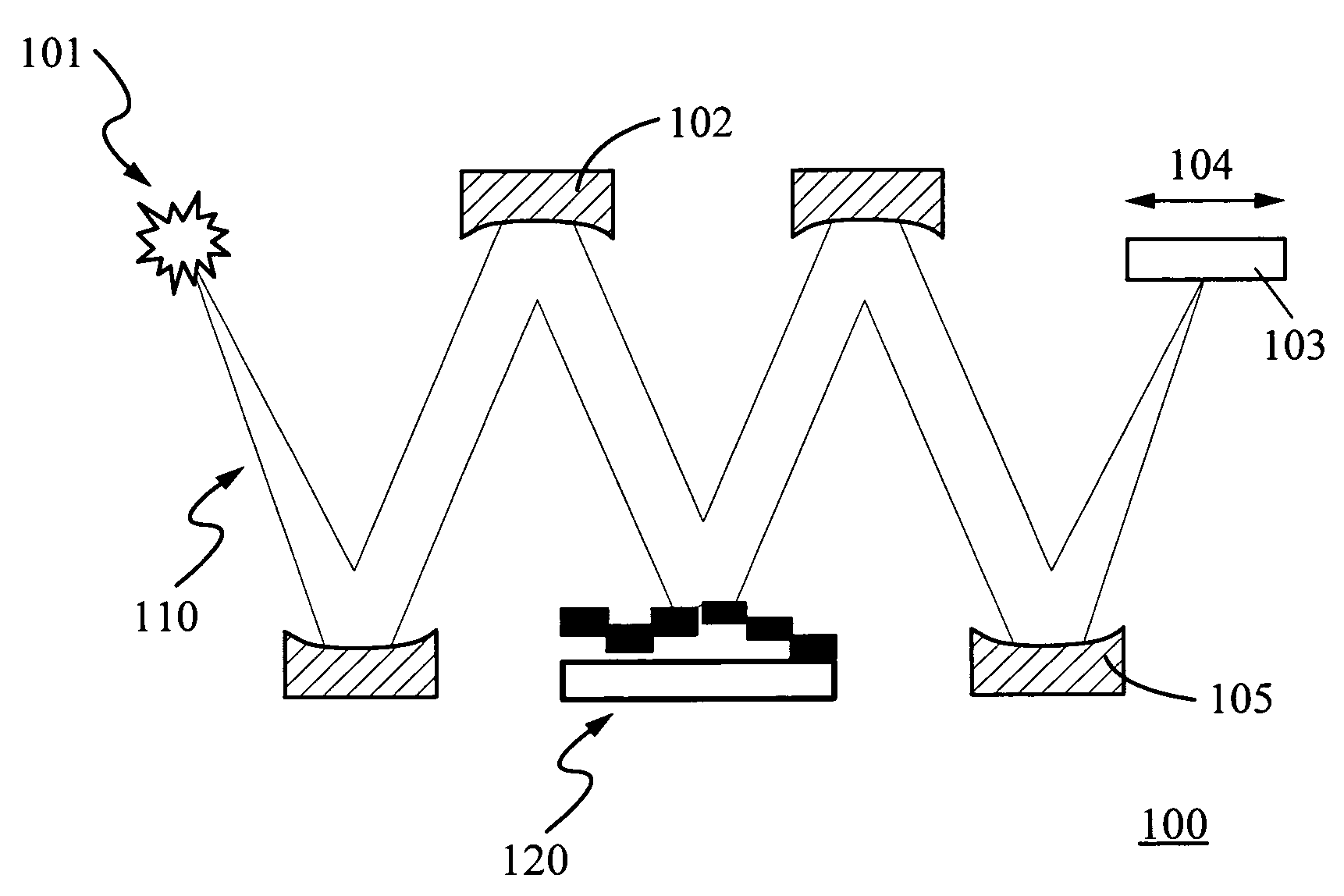

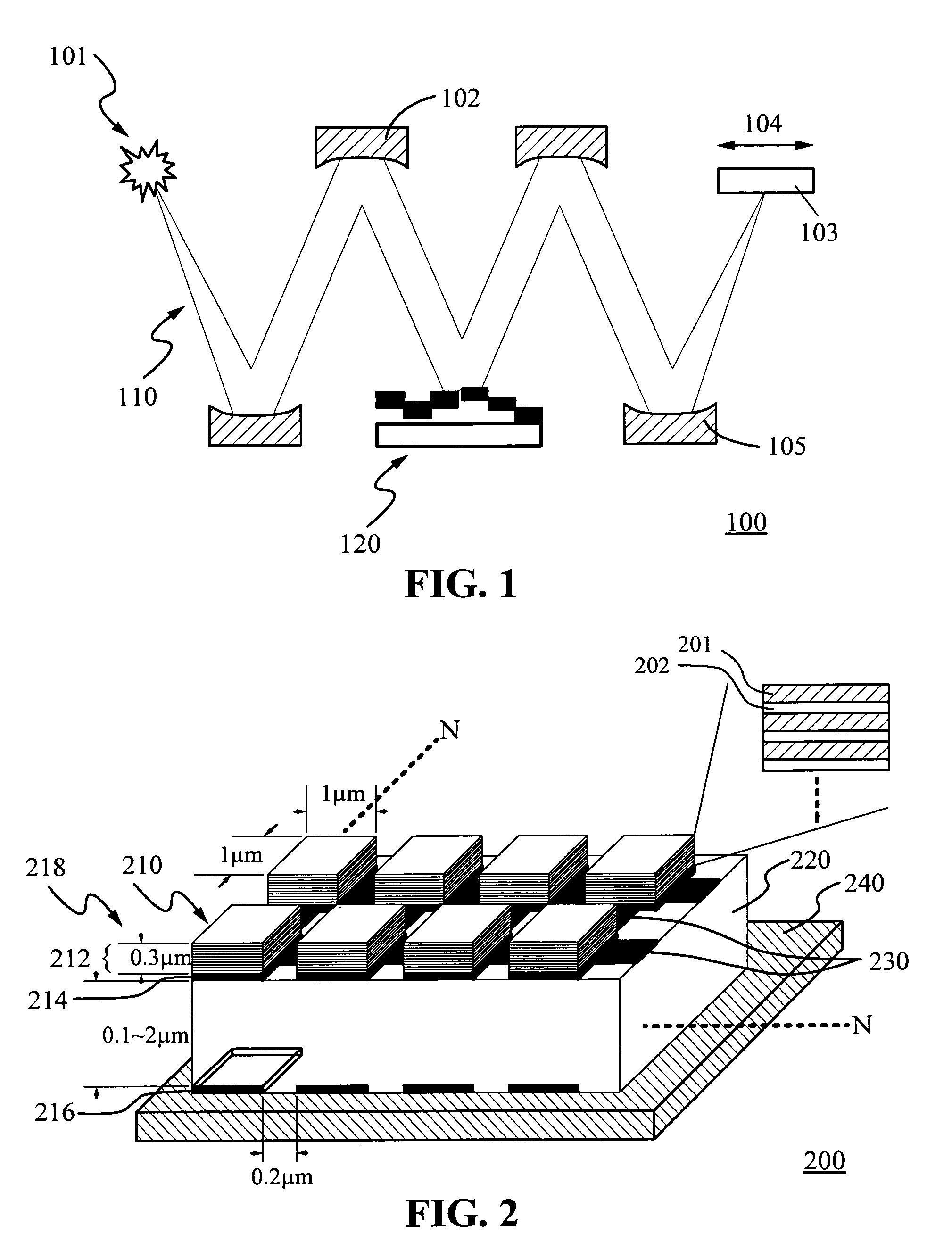

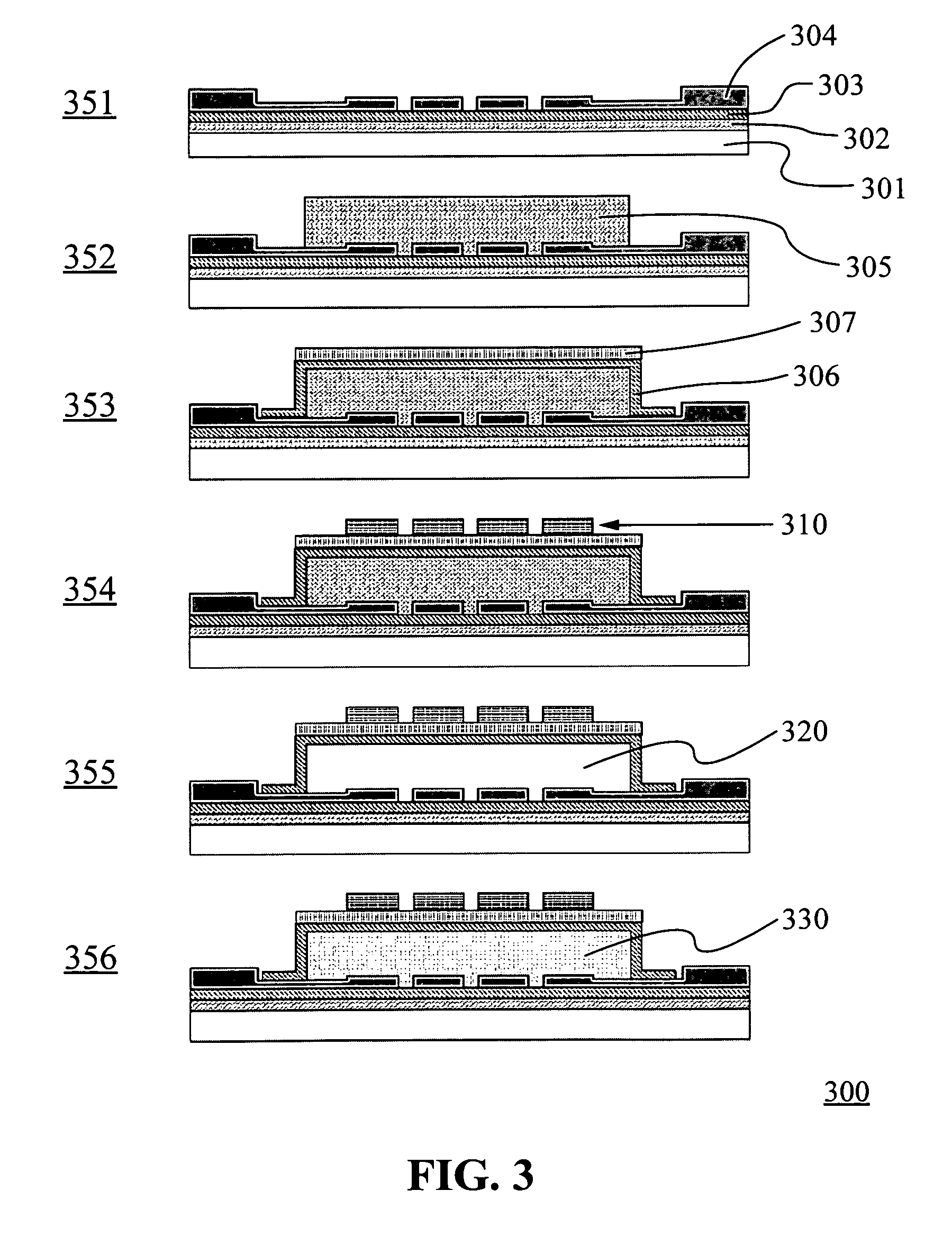

Elastomer spatial light modulators for extreme ultraviolet lithography

InactiveUS7092138B2Simplifies voltageSimple addressingMirrorsHandling using diffraction/refraction/reflectionCapacitanceElastomer

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

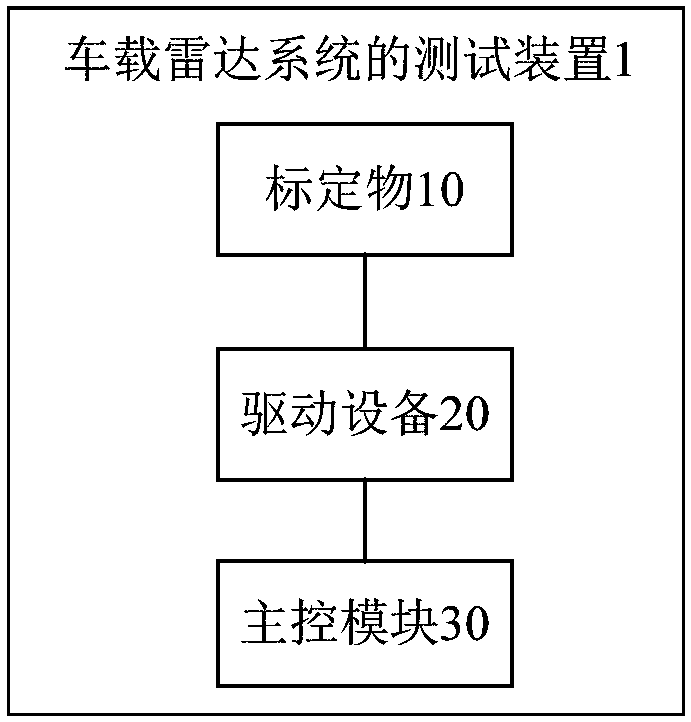

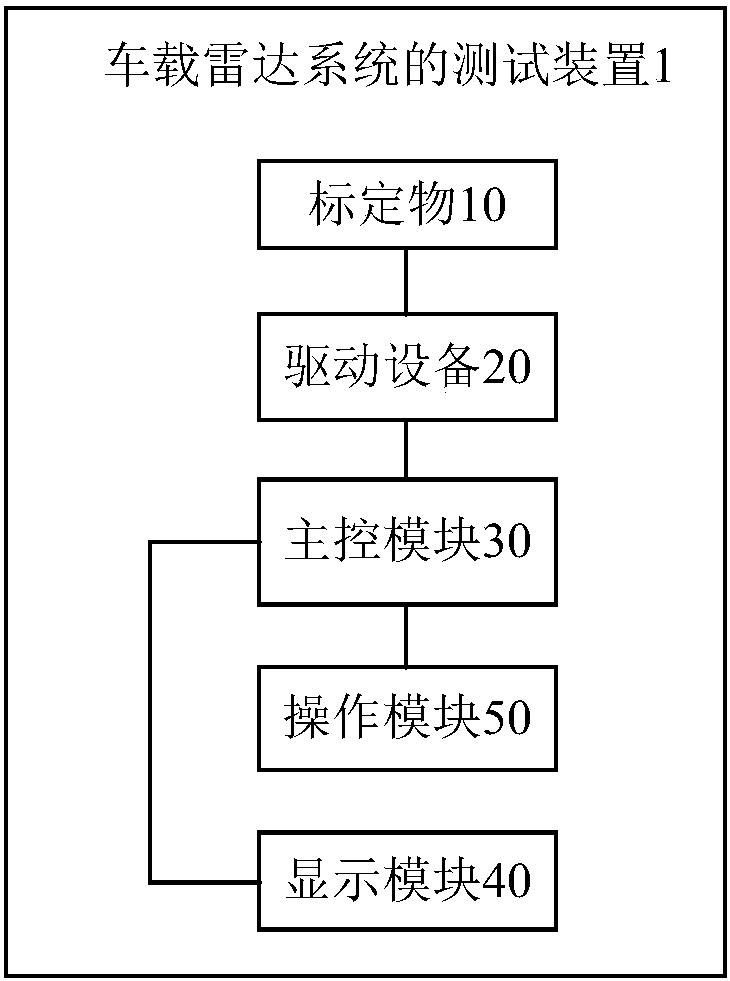

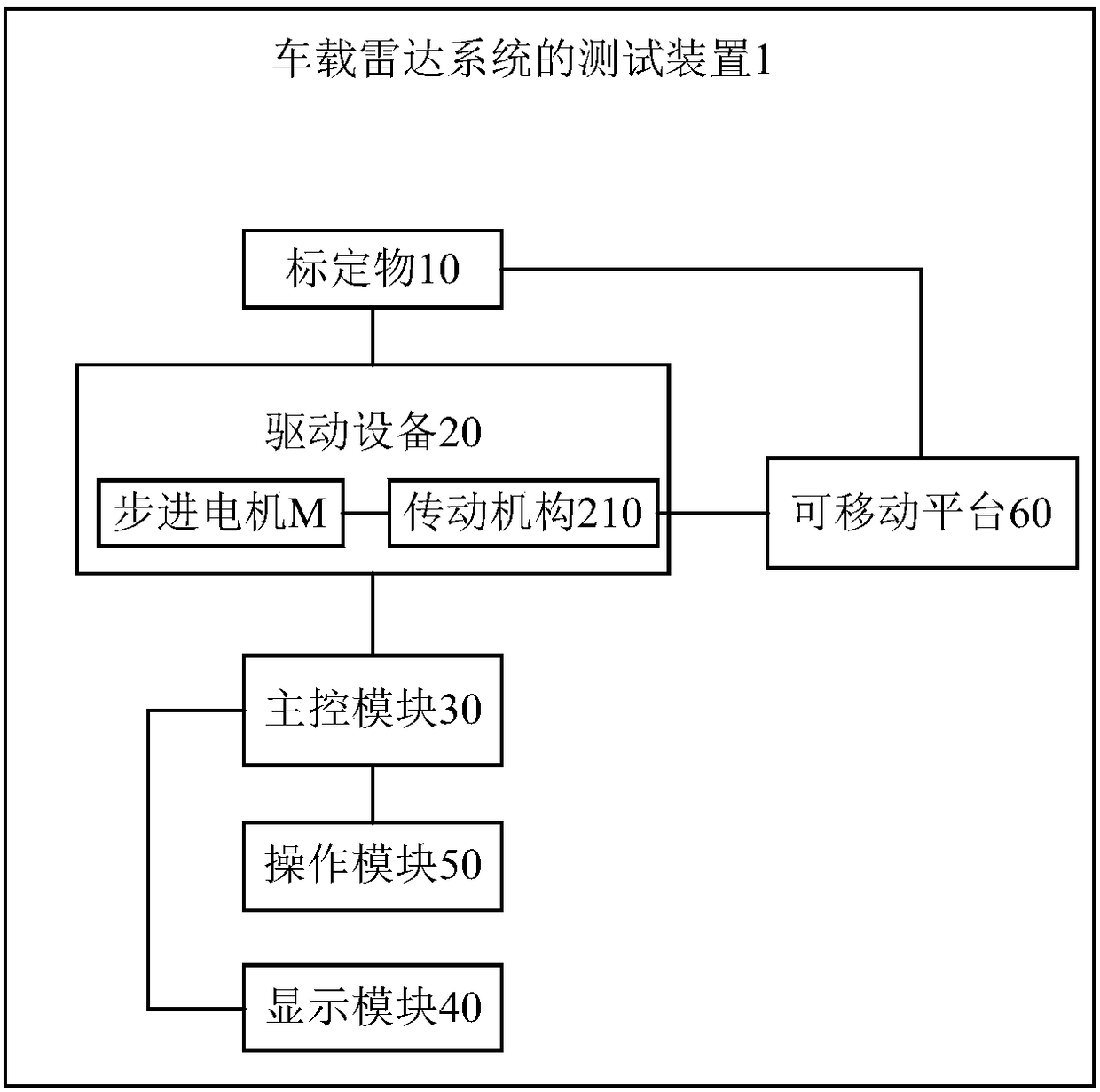

Testing device and method for vehicle-mounted radar system

InactiveCN108594189AEfficient and convenient testingWave based measurement systemsRadar systemsComputer module

The invention discloses a testing device and method for a vehicle-mounted radar system, wherein the testing device comprises: a calibration object; a driving device which is used for driving a calibration object to move according to a driving signal; and a main control module which is connected with the driving device and communicated with the vehicle-mounted radar system. The main control moduleis configured to send a driving signal to the driving device, acquire the moving distance of the calibration object, and receive the detection information of the calibration object by the vehicle-mounted radar system, and test the performance of the radar system according to the moving distance and the detection information. The device according to the invention can test the performance of the radar system conveniently and efficiently.

Owner:BAIC MOTOR CORP LTD

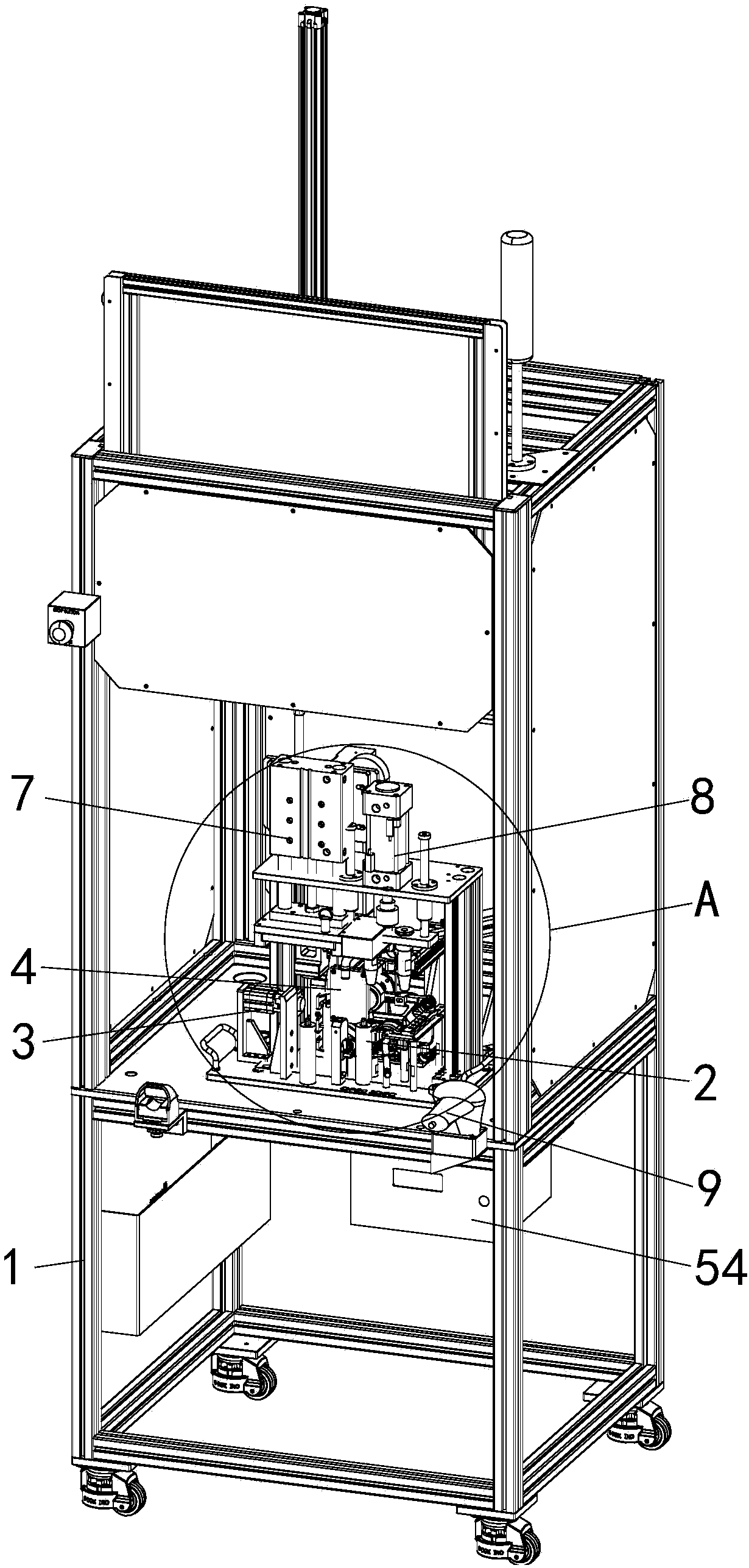

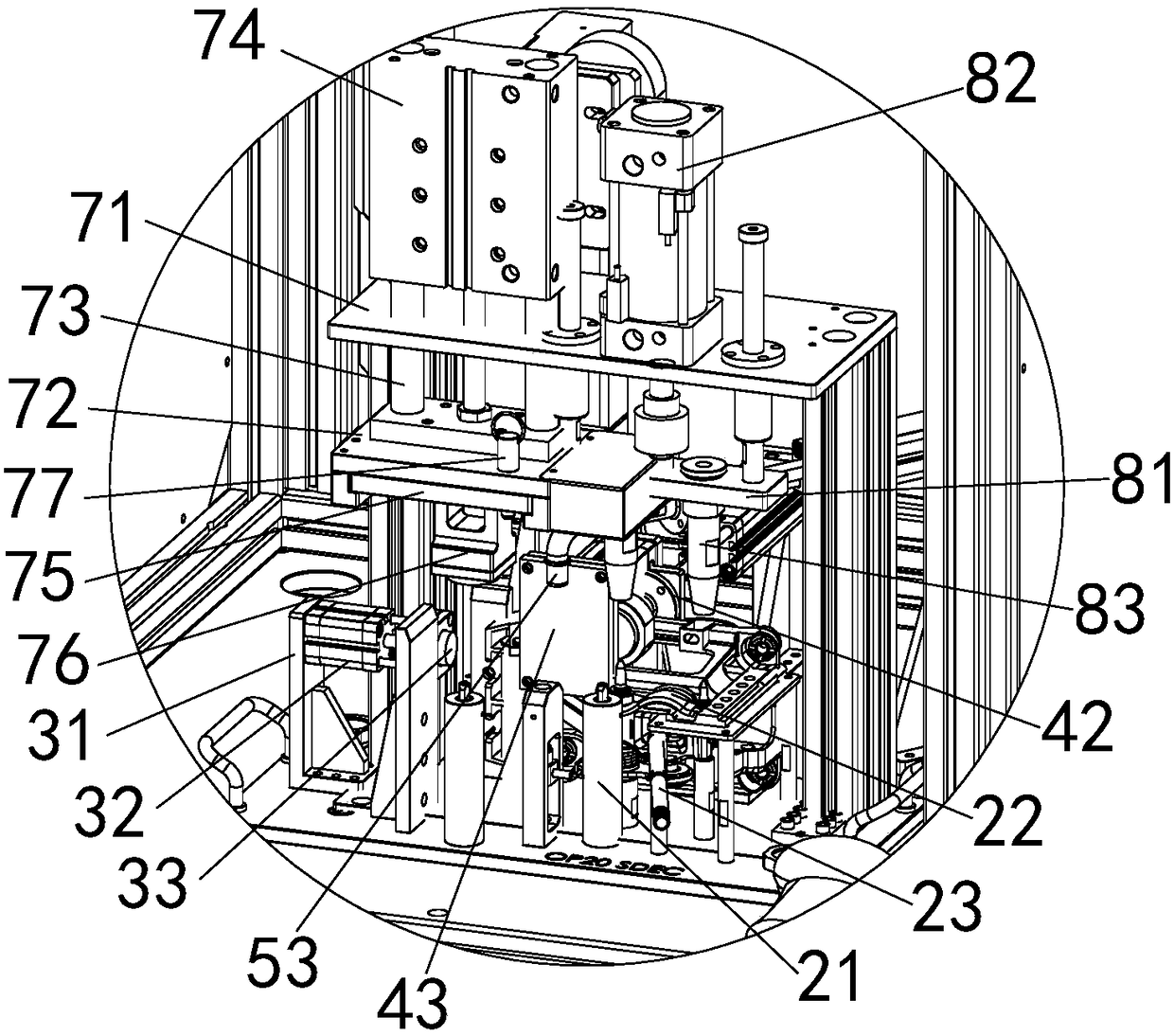

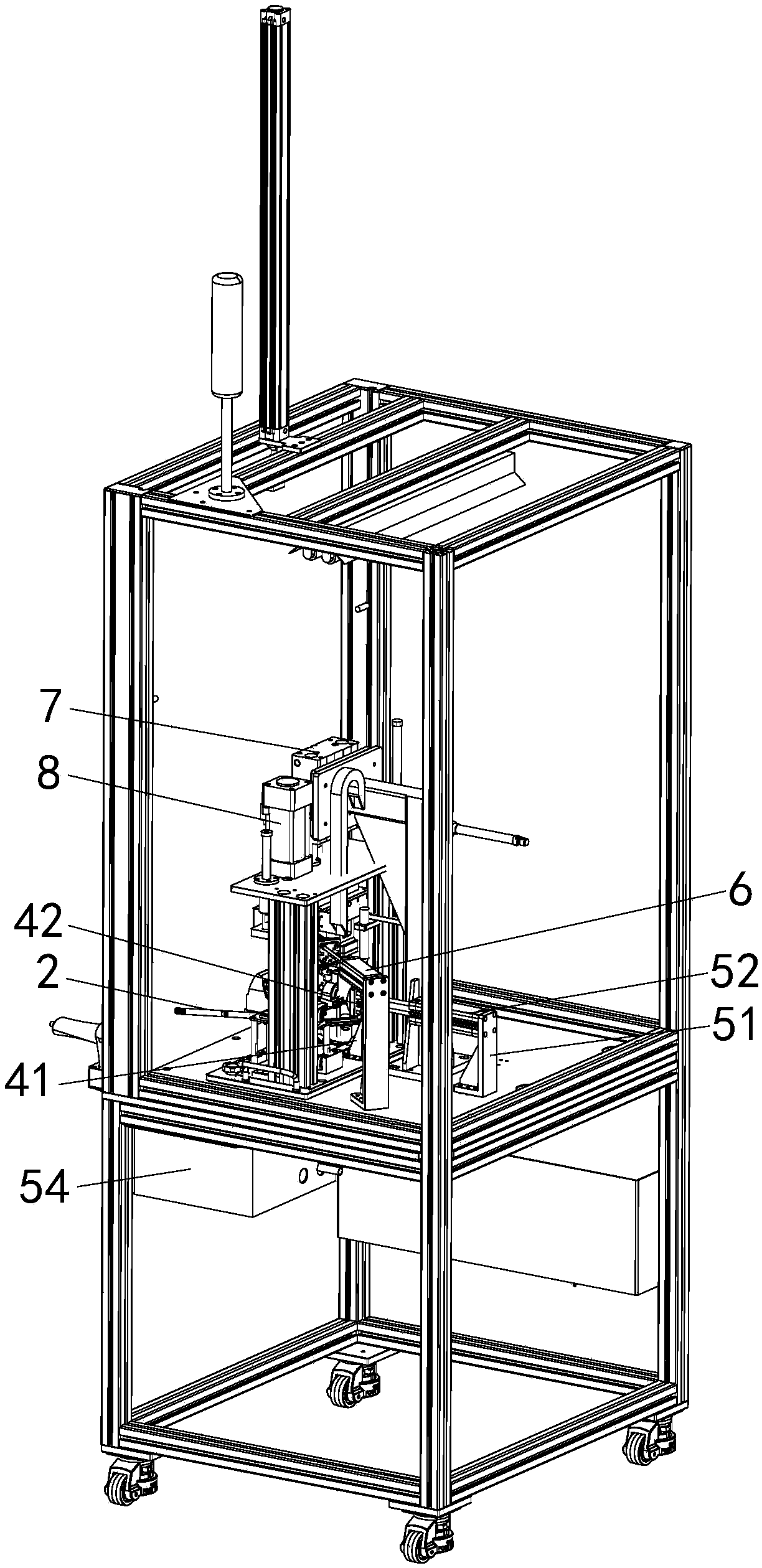

Test equipment for intelligent vacuum cleaner handle

PendingCN108627763AImplement automated testingEfficient and convenient testingElectronic circuit testingPressure functionFunctional testing

The invention provides test equipment for an intelligent vacuum cleaner handle. The test equipment for the intelligent vacuum cleaner handle comprises a frame, and a positioning mechanism and a test mechanism which are arranged in the frame, wherein the test mechanism comprises a power button test unit, a gear lamp test unit, a gear shift button test unit, a high voltage test unit, a working status lamp test unit, an unlock test unit, a vacuum negative pressure test unit and a communication module. The positioning mechanism is used for positioning the vacuum cleaner handle; the power button test unit is used for carrying out a click test on a power button; the gear lamp test unit is used for carrying out a photo comparison test on the color of a gear lamp; the gear shift button test unit is used for carrying out the click test on a gear shift button; the high voltage test unit is used for testing high voltage performance; the working status lamp test unit is used for testing a workingstatus lamp; the unlock test unit is used for testing an unlock function; the vacuum negative pressure test unit is used for testing a vacuum negative pressure function; and the communication module is connected with external test equipment. Real-time communication is realized, an automated test is realized, and the test is convenient and efficient.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

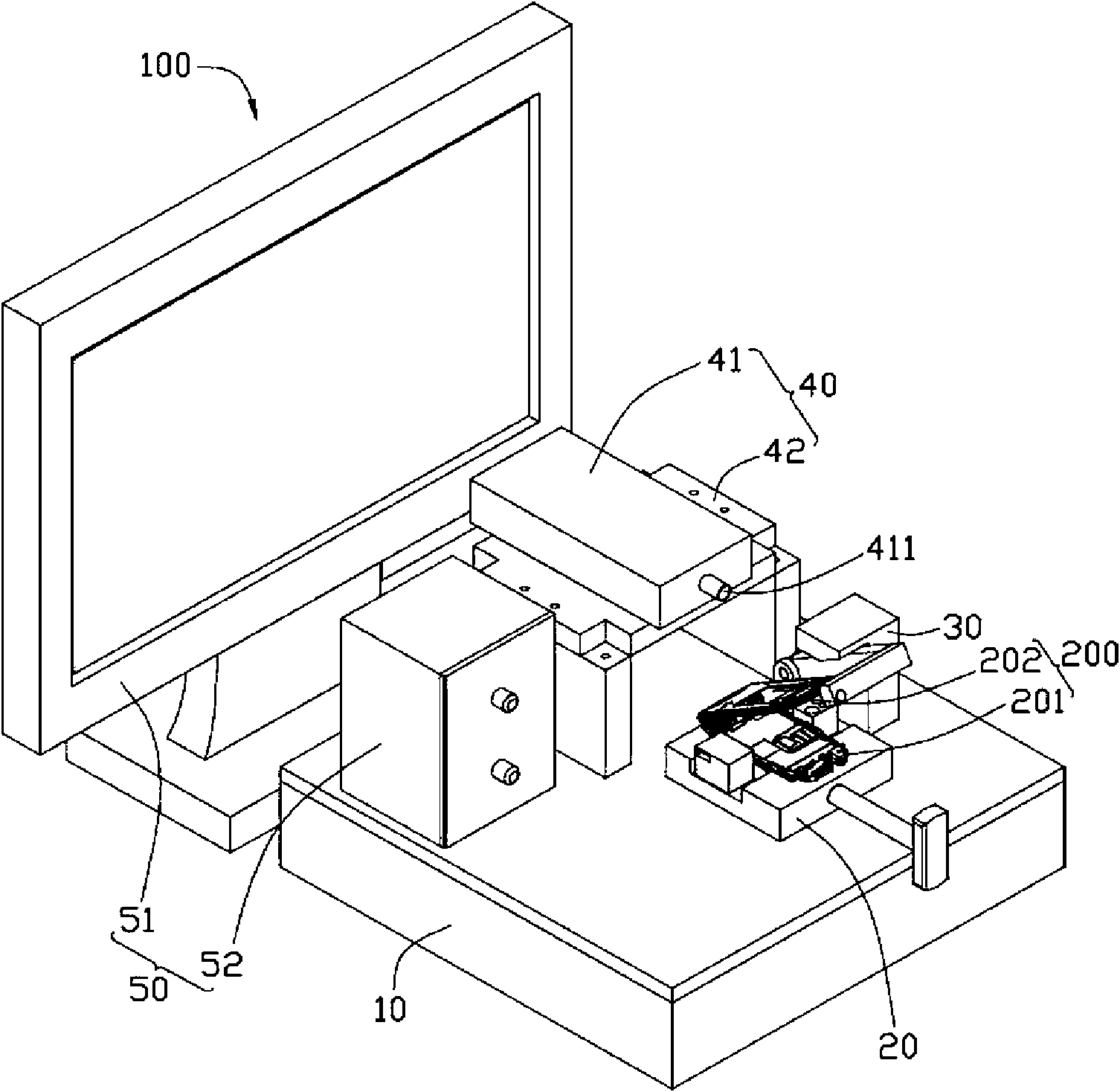

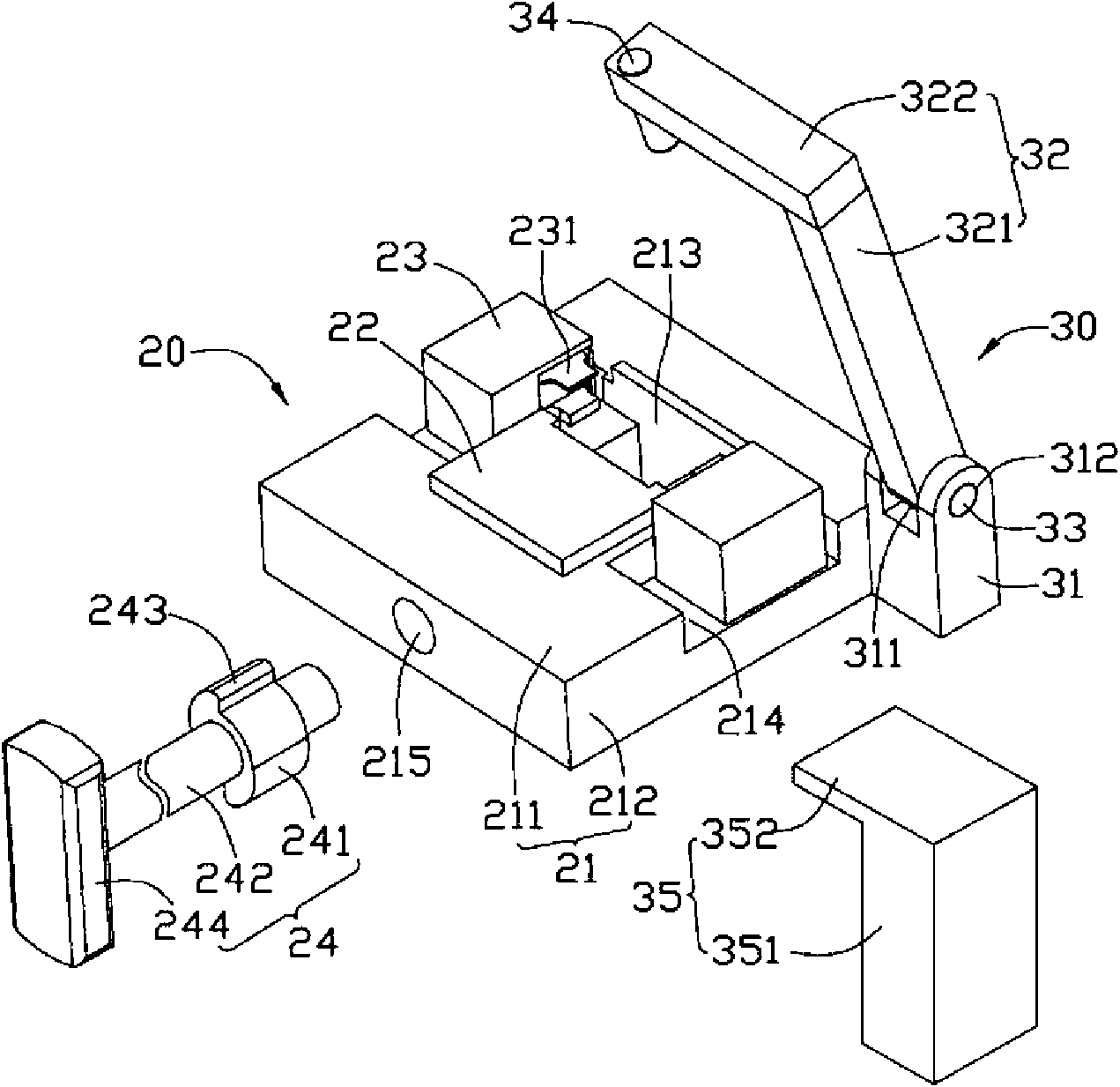

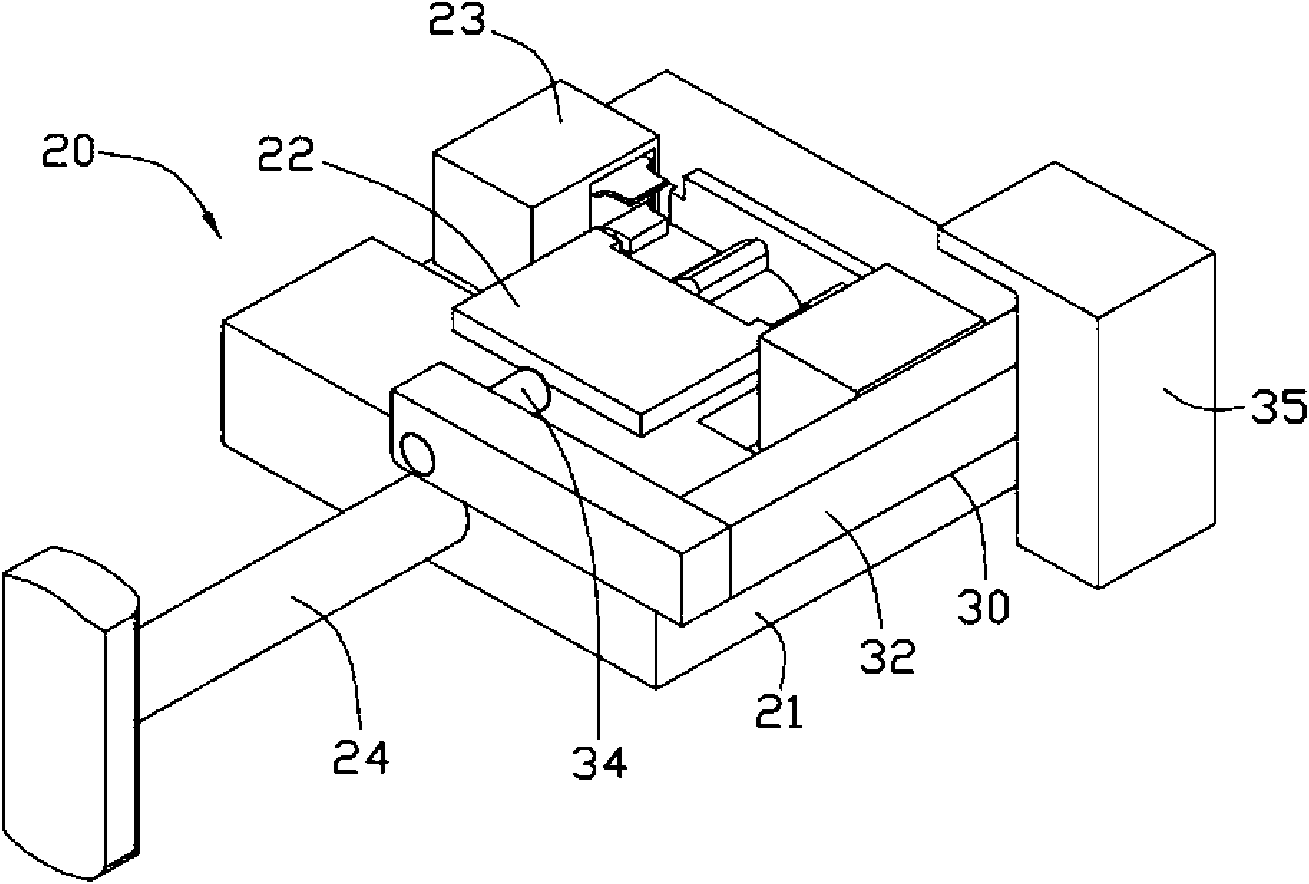

Flip performance testing system of electronic device

InactiveCN102109415AEfficient and convenient testingMachine part testingForce sensorsElectric signal

The invention discloses a flip performance testing system of an electronic device which is used for testing the flip performance of the flip type electronic device comprising a main body and a cover body, wherein the flip performance testing system of the electronic device comprises a supporting mechanism, a rotating mechanism, a sensing device, a driving device and a controlling device; the supporting mechanism is used for supporting the electronic device and locating the main body; the controlling device is used for controlling the driving device to drive the rotating mechanism to rotate the cover body to a preset critical angle; the cover body is automatically opened till the cover body is in contact with the sensing device and is exerted with pressure; the sensing device is used for converting the pressure into an electric signal and transmitting to the controlling device; and the controlling device analyzes the signal to judge whether the flip performance of the electronic device is normal.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Water pipe pressure testing machine

PendingCN106197895AConvenient and efficient testingThe operation process is simpleMeasurement of fluid loss/gain rateMaterial strength using repeated/pulsating forcesAutomatic controlWater pipe

The invention relates to a water pipe pressure testing machine. The water pipe pressure testing machine comprises a machine body and a pressure pipeline. The pressure pipeline is arranged in the machine body and provided with a gas inlet used for being connected with a gas source, and the gas inlet is located in one outer surface of the machine body. The part, at the gas inlet end, of the pressure pipeline is connected with an oil and water separator and a gas regulating valve in series in sequence, and is divided into a first pressure pipe branch and a second pressure pipe branch at the gas outlet part of the gas regulating valve, wherein the first pressure pipe branch and the second pressure pipe branch are connected in parallel. According to the testing machine, gas tightness testing and service life testing are unified in the machine body, multiple water pipe testing connectors are arranged, and thus testing is convenient and high in efficiency; a PLC is adopted for carrying out automatic control, and the operation process is easier; a display screen and an indicating light are arranged, and thus the testing process and a result are more visual and clearer; compared with the prior art, water pipes can be tested more conveniently and faster, and the water pipe pressure testing machine is accurate, reliable, high in economic applicability and suitable for vigorous application and popularization.

Owner:SANMEN VOCATIONAL SECONDARY SPECIALIZED SCHOOL

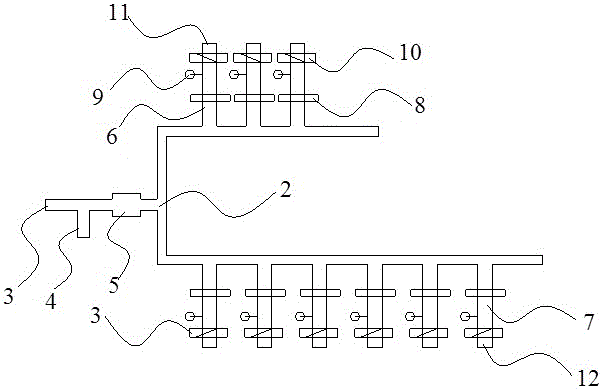

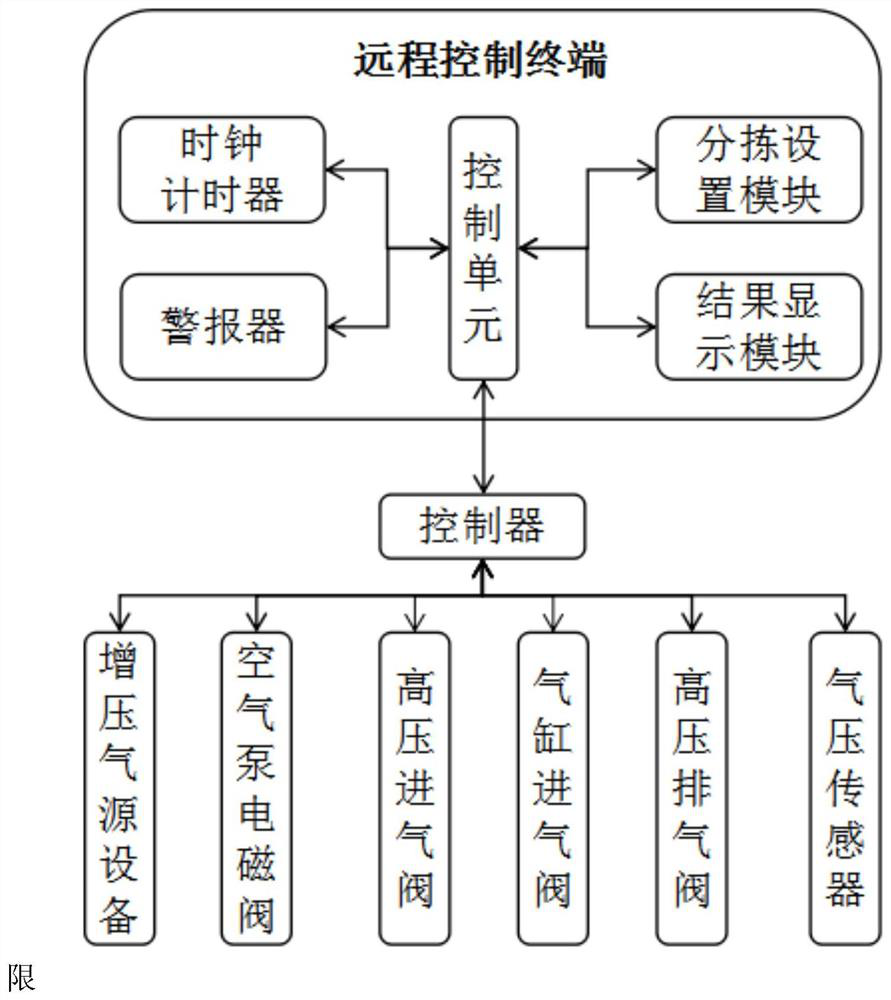

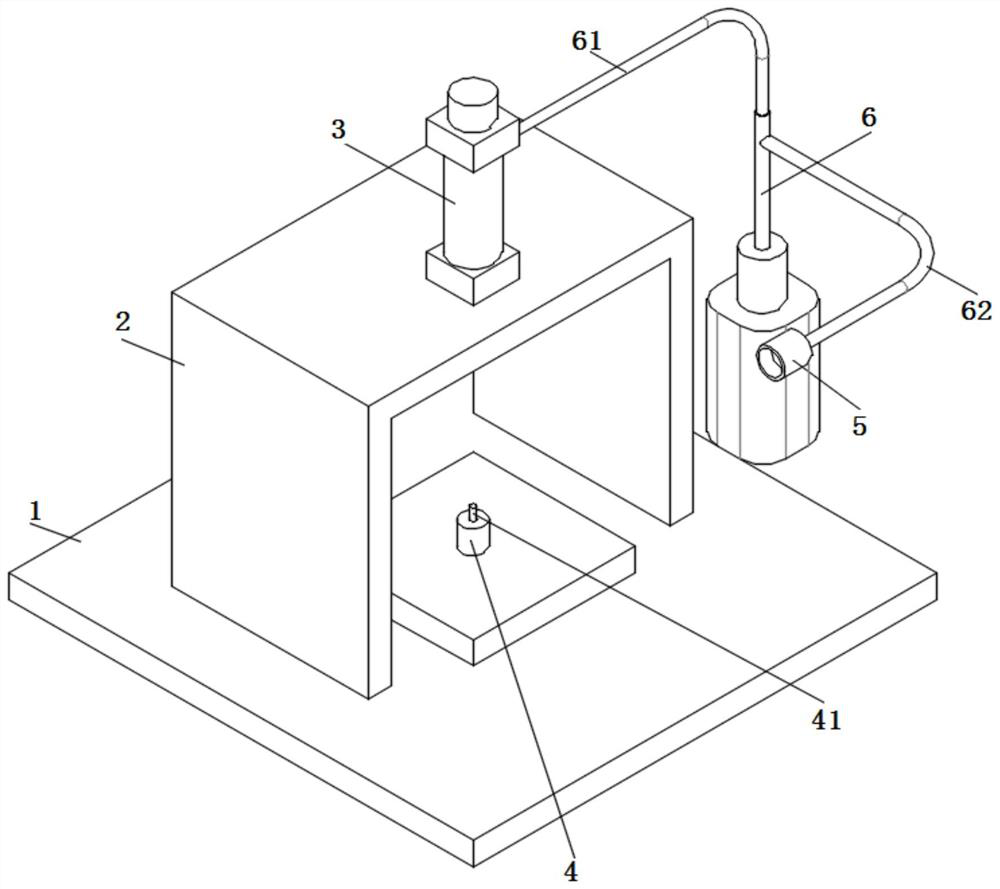

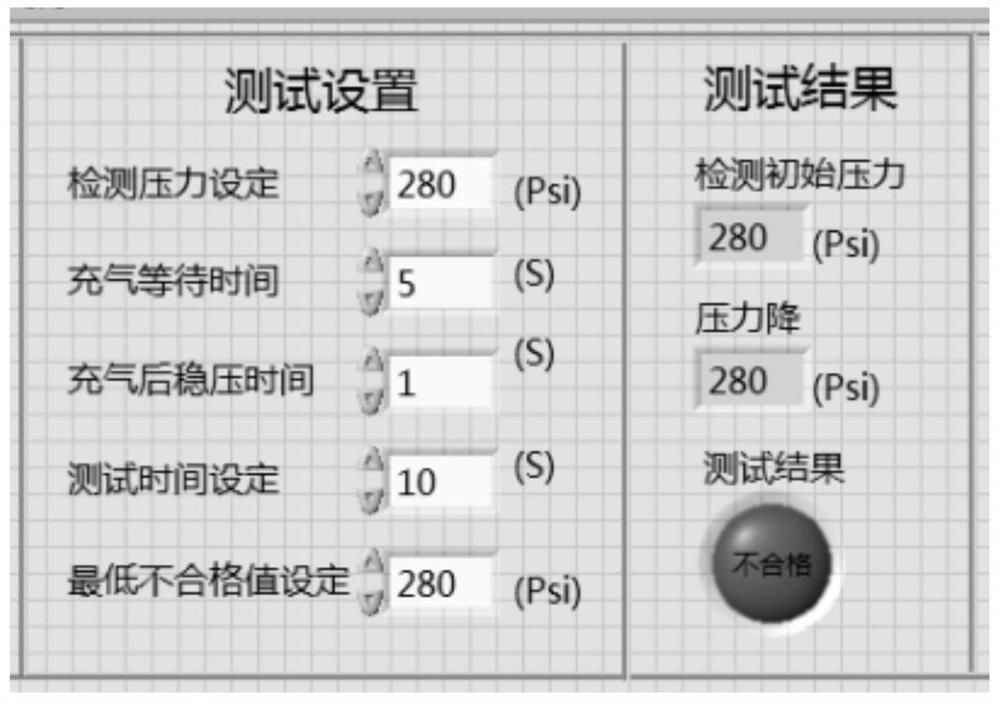

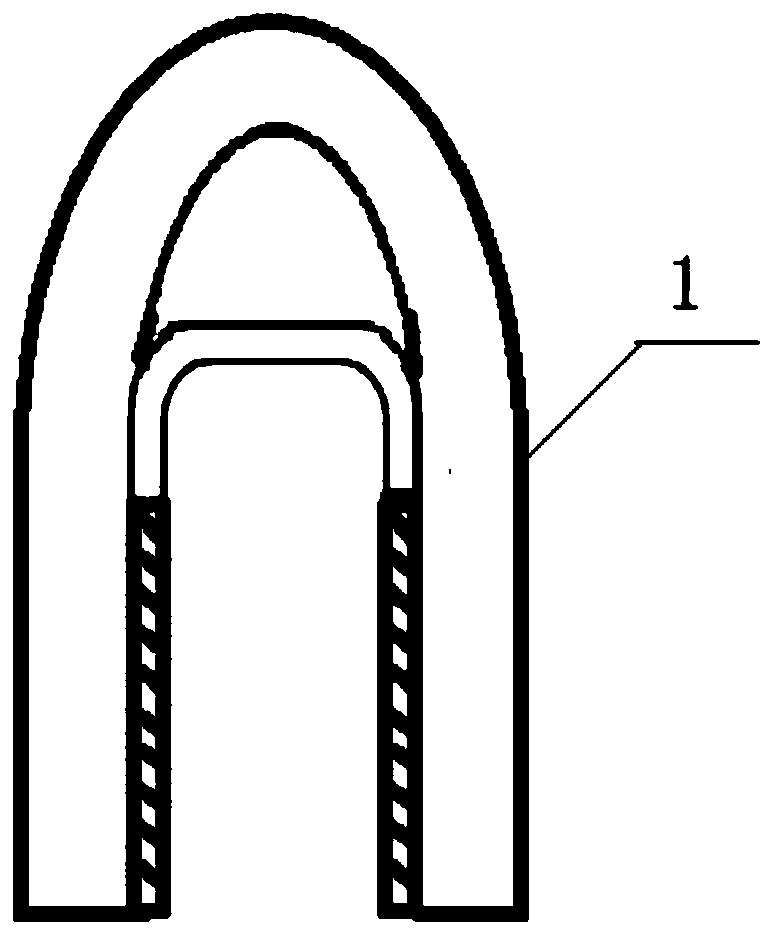

Air pump electromagnetic valve element sorting system and working method thereof

ActiveCN112304771ADetection adaptationEasy to sortMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesExhaust valveRemote control

The invention discloses an air pump electromagnetic valve element sorting system and a working method thereof. The system comprises a fixing base, a U-shaped frame, an air cylinder, an air pump electromagnetic valve, a cover cap, pressurization air source equipment, a high-pressure air inlet valve, a high-pressure exhaust valve, an air pressure sensor and a controller. The air pressure sensor detects air pressure information in a high-pressure sealing cavity and transmits the air pressure information to the controller; the remote control terminal transmits a control command to the controller;the controller controls opening and closing of the pressurization air source equipment, the air pump electromagnetic valve, the high-pressure air inlet valve and the high-pressure air outlet valve according to the control command; rapid and efficient detection of the pressure-resistant value of the valve element of the air pump electromagnetic valve is achieved, sorting of the air pump electromagnetic valve is facilitated, and the rate of certified products is increased.

Owner:ZIBO TAIZHAN MECHANICAL & ELECTRICAL

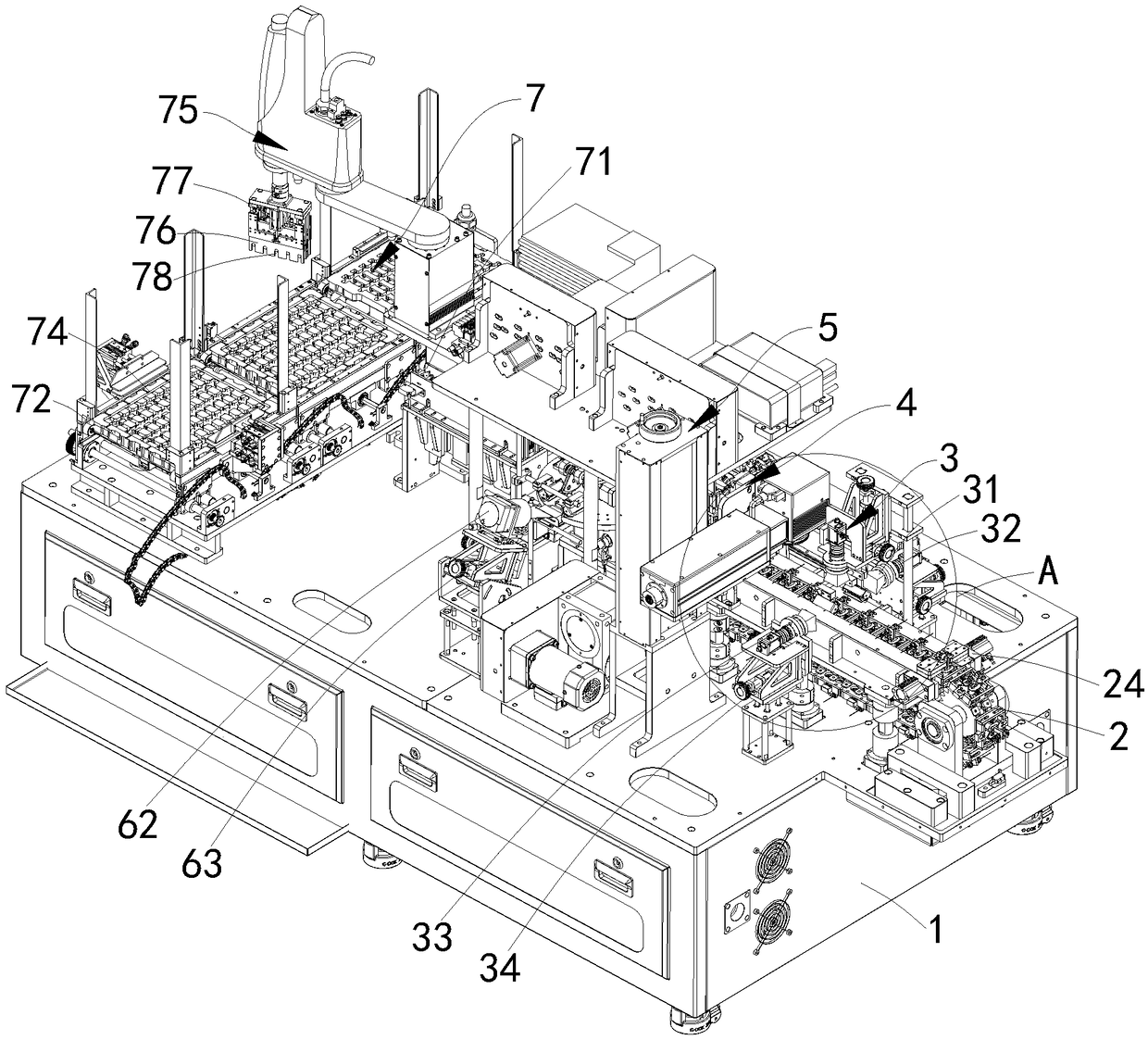

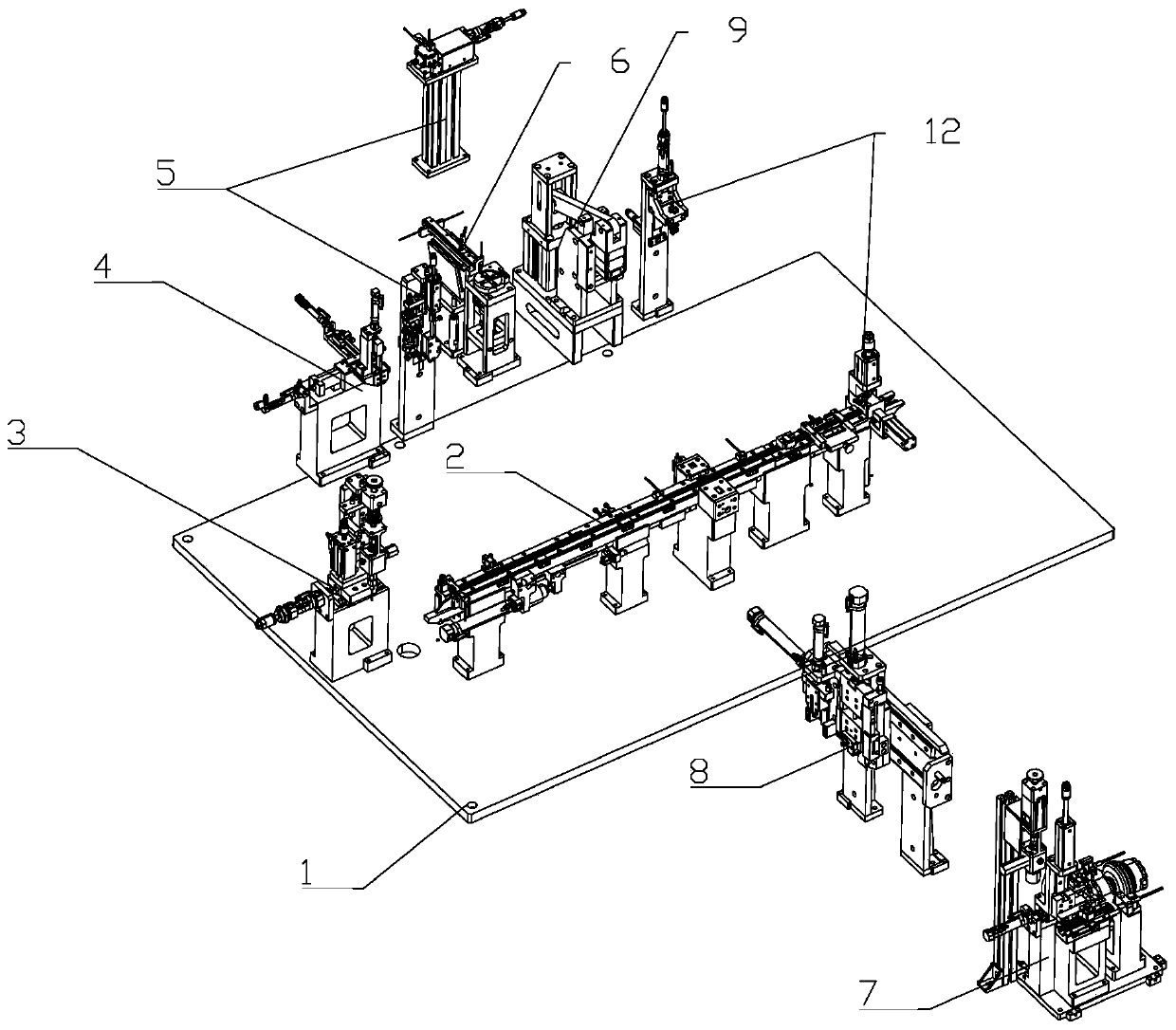

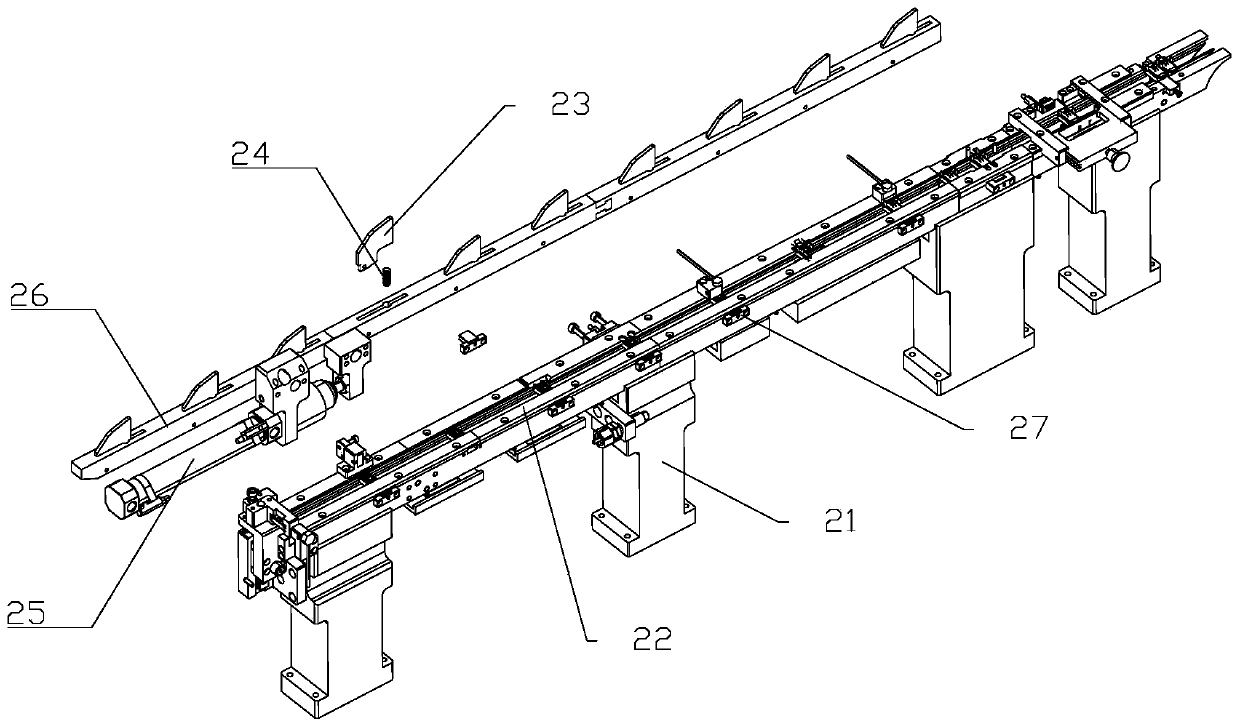

Full-automatic production equipment and full-automatic production method for slide switch

InactiveCN111180231AAvoid interferencePrevent the problem that the too long end still stays in the feeding seatElectric switchesProcess engineeringMechanical engineering

The invention relates to the technical field of slide switch production. The invention discloses full-automatic production equipment for a slide switch. The full-automatic production equipment comprises a rack, and a material passing device, a base positioning device, a handle feeding device, a spring feeding device, a sliding sheet feeding device, an upper cover feeding device, a synchronous carrying device, a pressing device and a testing and sorting device, which are arranged on the rack, wherein the base positioning device, the handle feeding device, the spring feeding device, the slidingsheet feeding device, the pressing device and the testing and sorting device are sequentially arranged at the side of the material passing device; the synchronous carrying device is located above thematerial passing device; the upper cover feeding device is arranged at the side of the synchronous carrying device; and the synchronous carrying device is located between the sliding sheet feeding device and the upper cover feeding device. The equipment has the advantages that the spring feeding success rate is high, the upper cover is fed in an overturning mode, limiting is conducted in sliding sheet assembling, and the production efficiency and the success rate are high.

Owner:陈如会

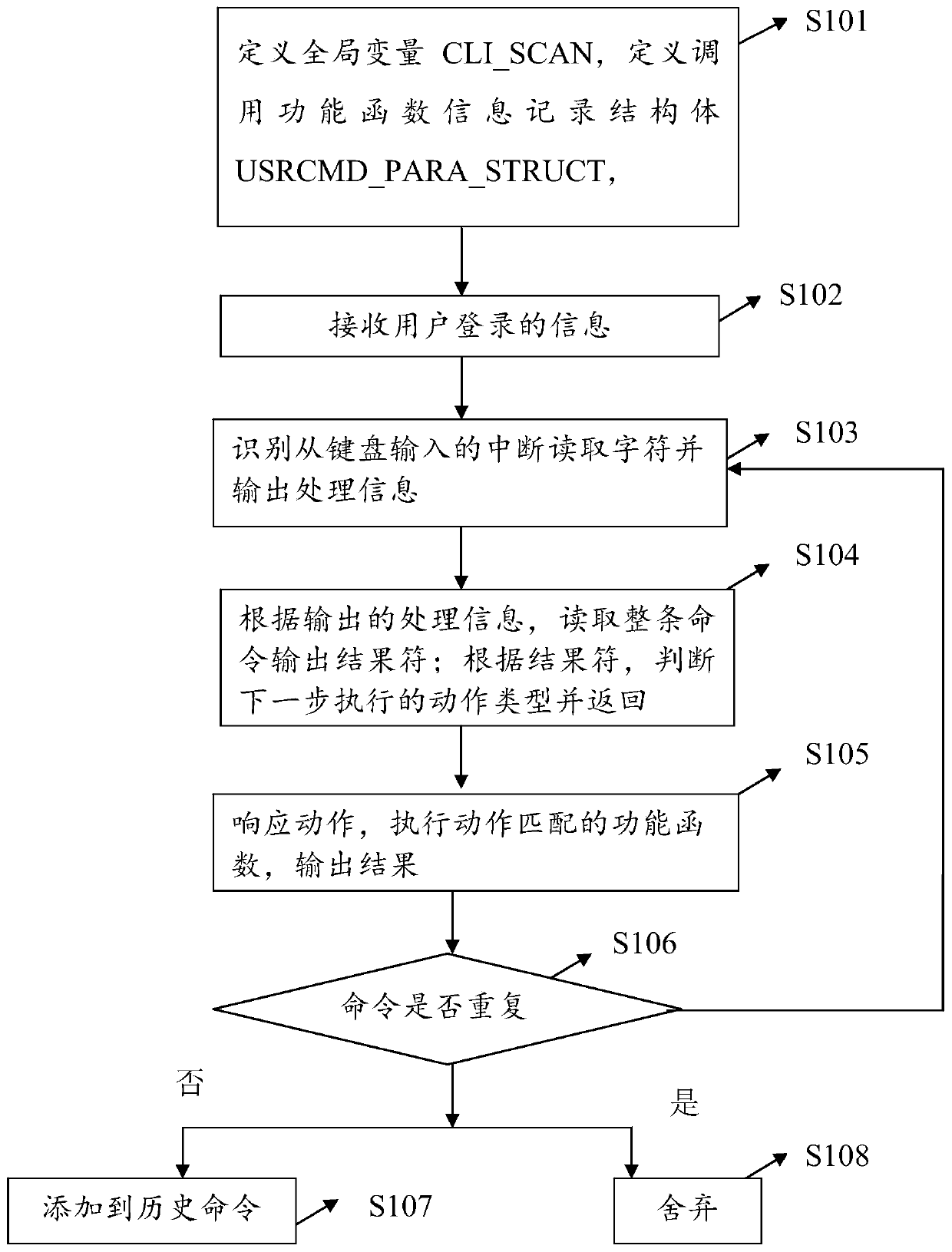

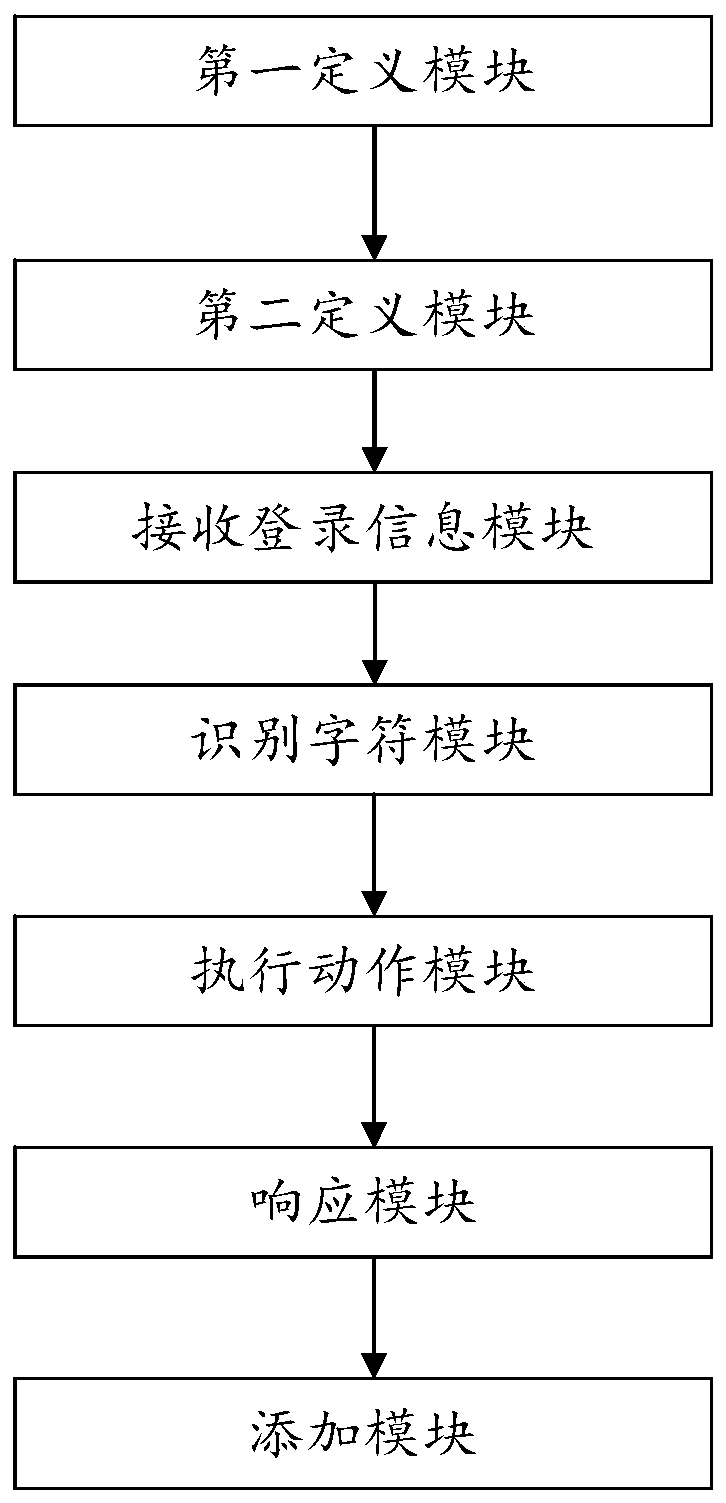

Method and system for realizing CLI command interface on single-chip microcomputer

ActiveCN111443915AEfficient and convenient configurationEfficient and convenient managementSoftware engineeringProgram loading/initiatingCommand-line interfacePerformance function

The invention provides a method for realizing a CLI command interface on a single chip microcomputer. The method comprises the following steps: firstly, defining a global variable CLI _ SCAN and calling a performance function information recording structural body USRCMD _ PARA _ STRUCT; receiving login information of the user; identifying an interrupted reading character input from the keyboard and outputting processing information; reading a whole command output result character according to the output processing information; judging the type of the action executed in the next step accordingto the result symbol and returning; responding to the action, executing a performance function matched with the action, and outputting a result; the command is added to a historical command. Based onthe method, the invention further provides a system for realizing the CLI command interface on the single-chip microcomputer, and the auxiliary functions which can be realized by the method comprise user permission setting and TAB key or-key supporting. Completing the commands, checking historical commands and the like. A man-machine interaction interface of a command line interface is realized, so that the configuration, management and test of the embedded single-chip microcomputer are more efficient, and scripts are automated.

Owner:山东华辰连科通信网络有限公司

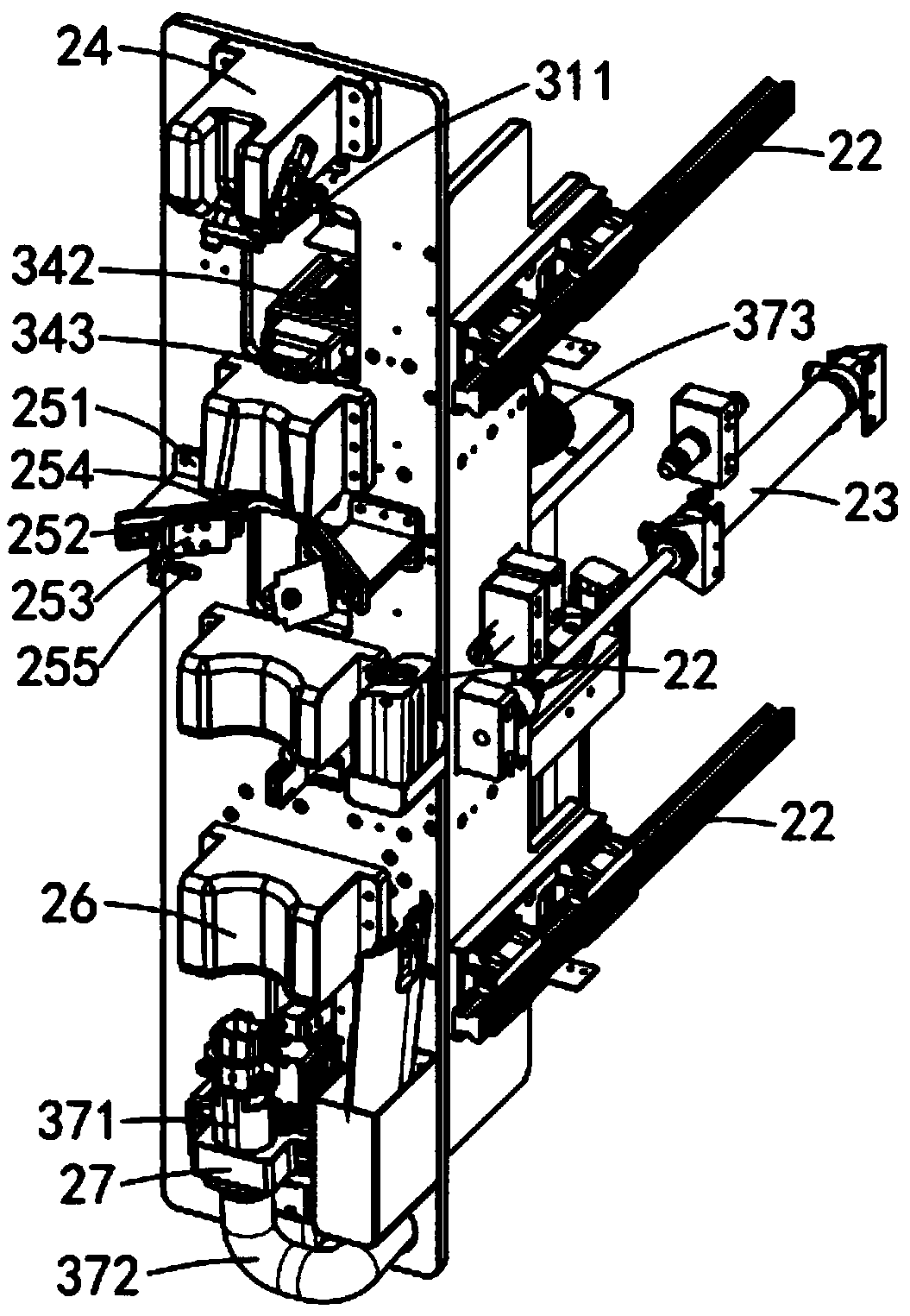

Intelligent dust collector head testing device

PendingCN109030058AImplement automated testingEfficient and convenient testingStructural/machines measurementElectricityMotor testing

The invention provides an intelligent dust collector head testing device. The testing device comprises a machine frame, a positioning mechanism arranged on the machine frame, a working state lamp andgear lamp detection mechanism arranged above the positioning mechanism, a main motor testing mechanism and a rotation testing mechanism arranged on one side of the positioning mechanism, and an imitation plug mechanism arranged at one end of the positioning mechanism and connected with the rotation testing mechanism. The positioning mechanism is used for positioning a to-be-tested product, namelya dust collector head; the imitation plug mechanism is electrically connected with the dust collector head; then the working state lamp and gear lamp detection mechanism is used for testing a workingstate lamp and a gear lamp on the dust collector head; the main motor testing mechanism is used for testing the rotating speed of a main motor of a dust collector; the rotation testing mechanism is used for testing joint rotation of the dust collector; the intelligent dust collector head testing device achieves automatic testing of the dust collector head; the testing of the working state lamp, the testing of the gear lamp, the testing of the rotating speed of the main motor and the testing of the joint rotation are integrated; and the detection is convenient and efficient.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

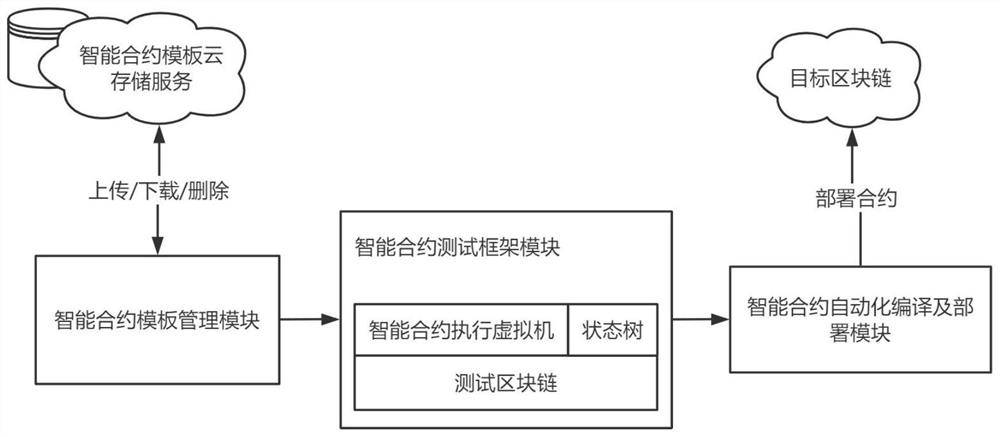

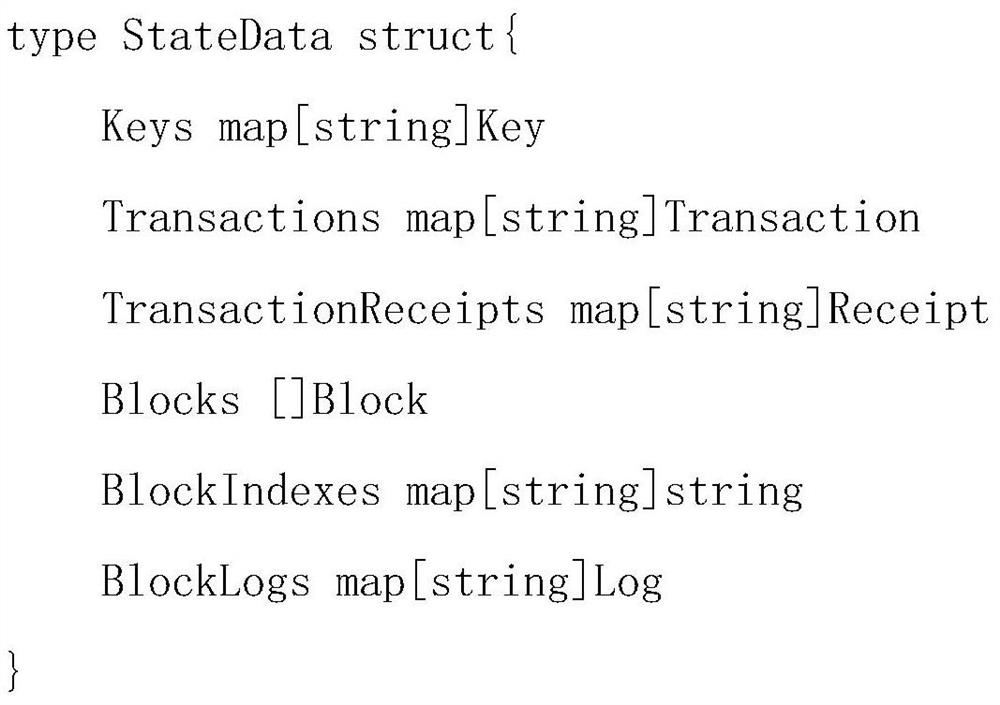

Intelligent contract one-stop development system and method

PendingCN113254054ASolve complex operationsImprove development efficiencySoftware maintainance/managementSoftware testing/debuggingTest frameSoftware engineering

The invention provides an intelligent contract one-stop development system and method. The intelligent contract one-stop development system comprises an intelligent contract template management module, an intelligent contract test framework module and an intelligent contract automatic compiling and deploying module. The intelligent contract template management module is used for receiving a command line instruction and managing an intelligent contract template, including uploading, downloading and deleting the intelligent contract template; the intelligent contract test framework module comprises the steps of generating an intelligent contract test file, and debugging and testing an intelligent contract code based on the generated intelligent contract test file; and the intelligent contract automatic compiling and deploying module is used for compiling and deploying according to a contract deploying sequence on the basis of intelligent contract names needing to be deployed according to pre-configured IP, port number and network number information of a specified block chain.

Owner:SHANGHAI WANXIANG BLOCK CHAIN CO LTD

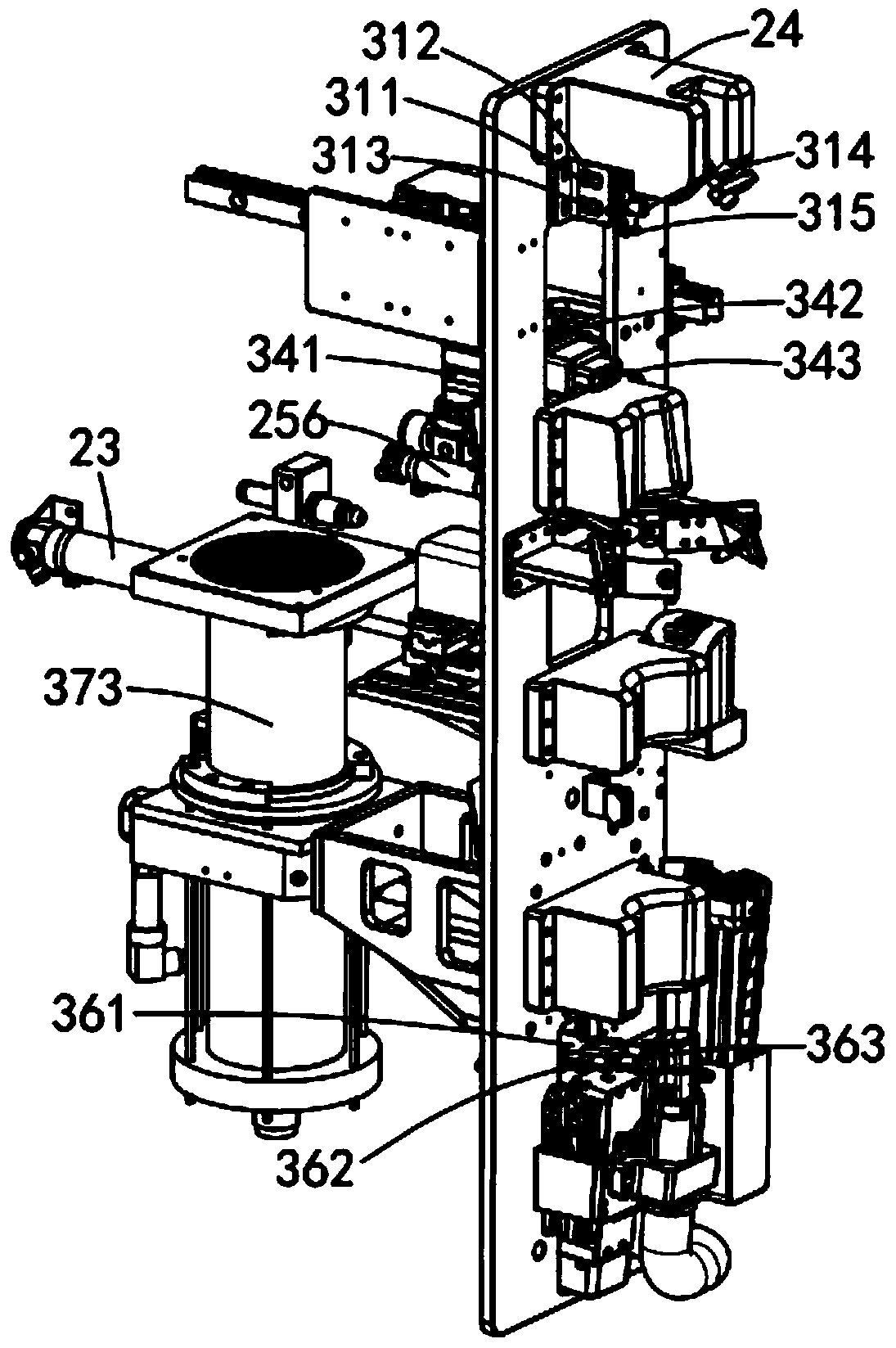

Sealing testing device

PendingCN108444647AEfficient and convenient testingImprove test accuracyDetection of fluid at leakage pointBiochemical engineeringTurbocharger

The invention provides a sealing testing device which comprises a frame, a positioning mechanism, a plugging mechanism, a plugging and clamping mechanism, a first air inlet testing mechanism, a secondair inlet testing mechanism, a marking mechanism and a dust removal mechanism. The positioning mechanism is arranged on the frame. The plugging mechanism, the plugging and clamping mechanism, the first air inlet testing mechanism, the second air inlet testing mechanism and the marking mechanism are arranged on the periphery of the positioning mechanism. The dust removal mechanism is arranged at the marking mechanism. The plugging mechanism is perpendicular to the plugging and clamping mechanism. A to-be-tested product, namely a turbocharger, is positioned by the positioning mechanism, one side of the product is plugged by the plugging mechanism, and the other side of the product is plugged and clamped by the plugging and clamping mechanism. Therefore, the product is completely positioned,a first air inlet of the product is tested by the first air inlet testing mechanism, another air inlet of the product is tested by the second air inlet testing mechanism, and after the testing is finished, the product is marked by the marking mechanism, and then the product is blown for dust removal by the dust removal mechanism, so that the turbocharger is subjected to positioning, air inlet testing, marking and dust removal automatically, the testing is convenient and efficient, the testing precision is high, and labor is saved.

Owner:SUZHOU UNIV OF SCI & TECH

Intelligent approach automatic fire extinguishing system

ActiveCN101797426BEfficient and convenient testingGuaranteed uptimeFire rescueFire alarmsControl systemCollection system

The invention relates to an intelligent approach automatic fire extinguishing system, which comprises a fire fighting agent storage tank combination system, an approach atomizer combination fire fighting system, an intelligent fire fighting control system and a fire monitor system. The intelligent fire fighting control system comprises a fire information collecting system, a central control system and a fire fighting device control system. The fire information collecting system collects fire field information and transmits to the central control system andor receives manual order and transmits the order to the fire fighting device control system. The central control system receives the information transmitted by the fire information collecting system andor the fire fighting device controlsystem, automatically generates the order or receives the manual input order and transmits the order to the fire fighting device control system. The fire fighting device control system receives the order transmitted by the fire information collecting system andor the central control system and adjusts the running state of the fire fighting agent storage tank combination system and the approach atomizer combination fire fighting system. The system is safe, reliable, high efficient, economical and environment-friendly and can be extensively applied to various fields.

Owner:苏州赛夫特消防科技有限公司

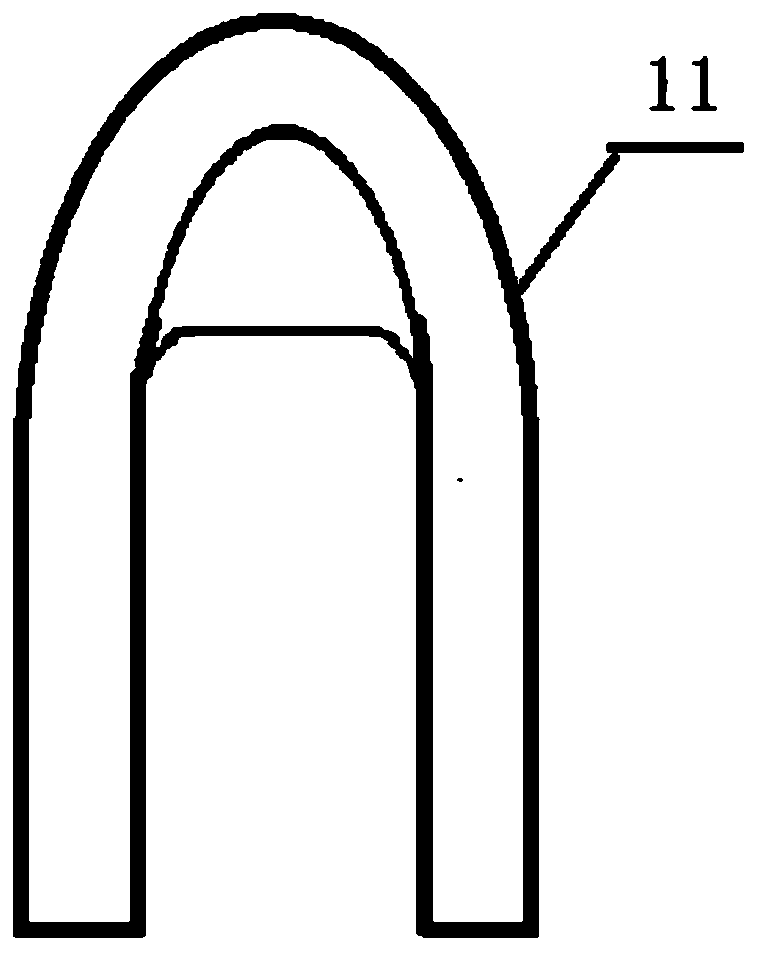

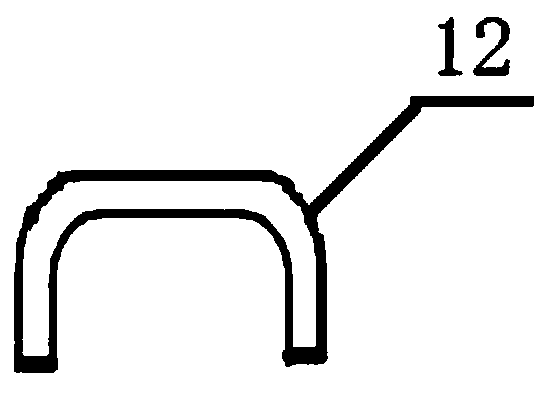

An intelligent tester for track circuit shunt parameters and its implementation method

InactiveCN106291317BIncrease contactEfficient and convenient shunt currentCurrent/voltage measurementElectronic circuit testingElectricityCopper wire

The invention relates to an intelligent track circuit shunt parameter tester and a test method thereof. The intelligent track circuit shunt parameter tester comprises a hand-held tool that matches the shape of the surfaces of steel rails and a test instrument that is connected to a contact copper board of the hand-held tool via a copper wire. The hand-held tool has three parts, namely, an integrated outer sheath with a handle, the contact copper board with the same arc shape as the surface of the steel rails and a rust-removing filing board. The copper wire is led out from the contact copper board of the hand-held tool. The instrument is arranged in a customized housing. Two copper pillars are installed at the top of the housing and are connected to the copper wire on the back of the housing. After the instrument is mounted in the housing, shunt electrical signals can be effectively obtained through the two copper pillars, and calculation is automatically carried out according to the electric signals. The technical scheme provided by the invention can solve the problem of poor contact of the tester which may be caused due to corrosion of the steel rail, and the rail surface voltage between the two steel rails and the shunt current after the two steel rails are shunted can be measured efficiently and conveniently.

Owner:袁伟家

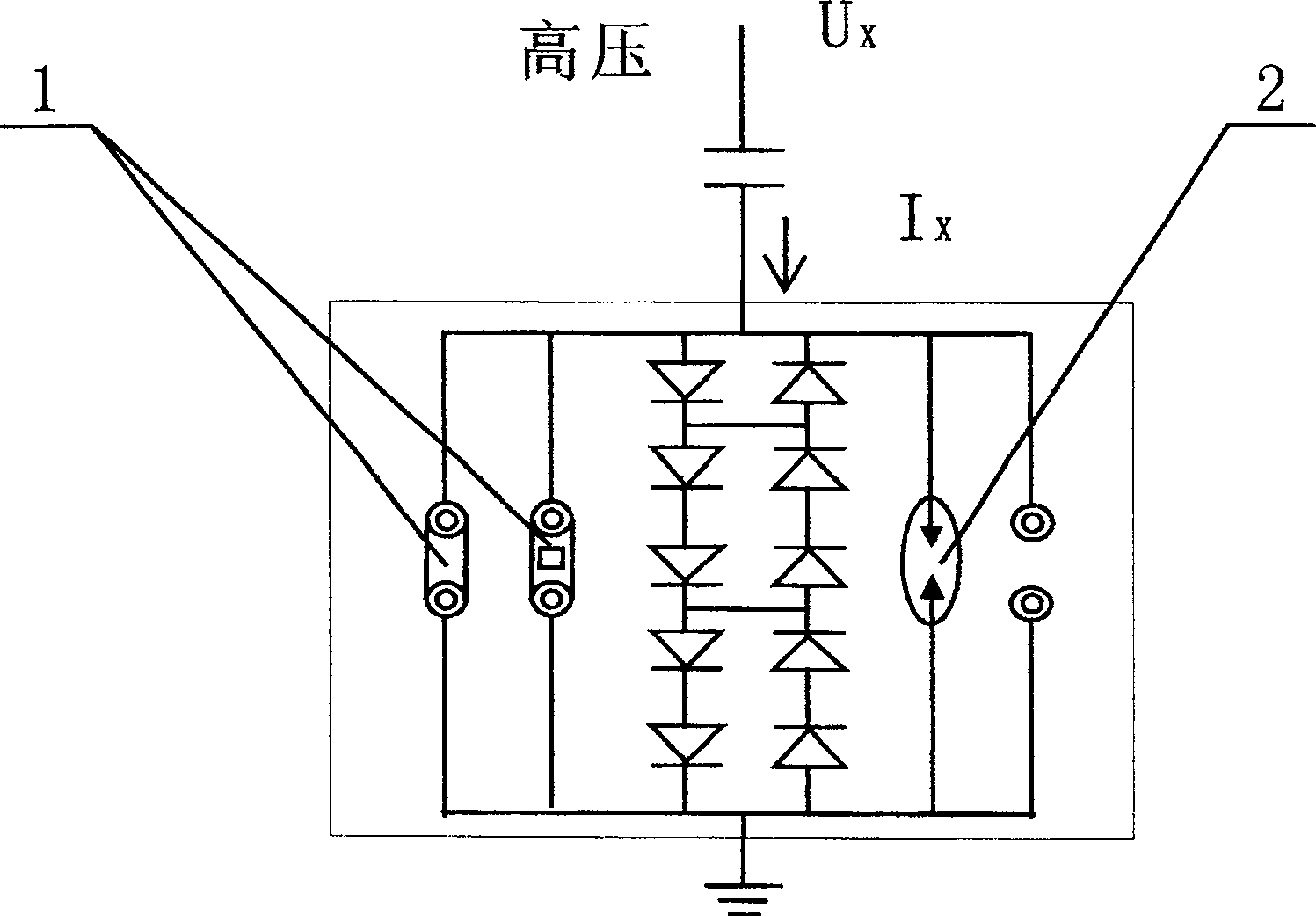

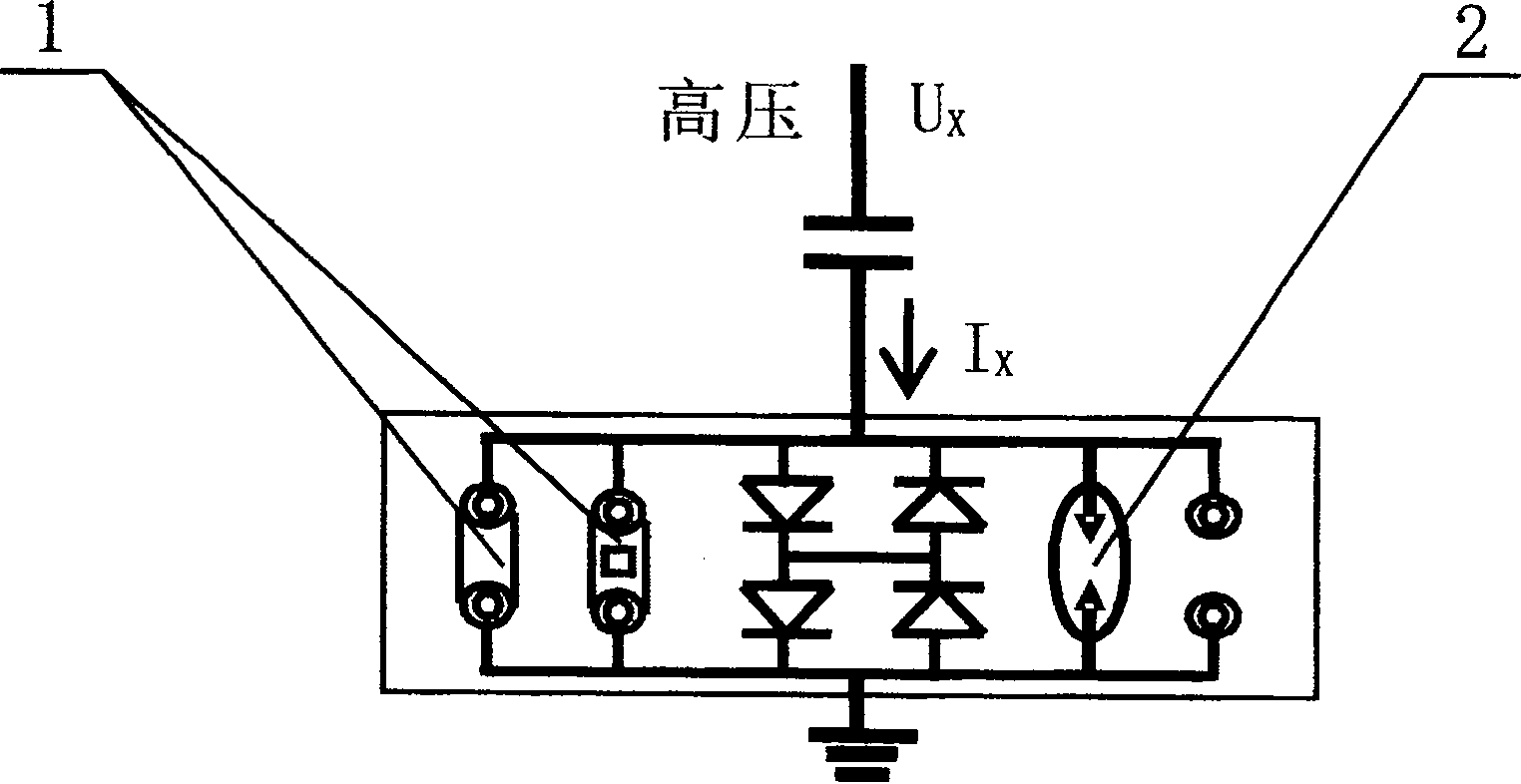

A power testing sampling protection unit

InactiveCN100524999CHigh sensitivityTimely and effective detection of insulation defectsArrangements resposive to fault currentInput impedanceEngineering

The invention relates to the power electronic technology field, in particular to a sampling protection unit used to test the insulation of the capacitive equipment. The protection unit is connected with the grounding wire of the tested equipment in series and is composed of a control circuit, a bleeder circuit and a protection circuit connected with each other in parallel. The control circuit is composed of a plurality of parallel connected short contact pieces. The bleeder circuit is composed of a diode bridge which makes the end screen smaller than the 5V. The protection circuit is composed of a discharge tube with the test end connected with the both ends of electric power test sampling protection unit. The input impedance of the electric power test sampling unit is too low, and is capable of being connected with the grounding wire of the tested equipment, which makes the on-line testing convenient, ensures the on-site use safety and prevents the accidental electric shock.

Owner:KGE

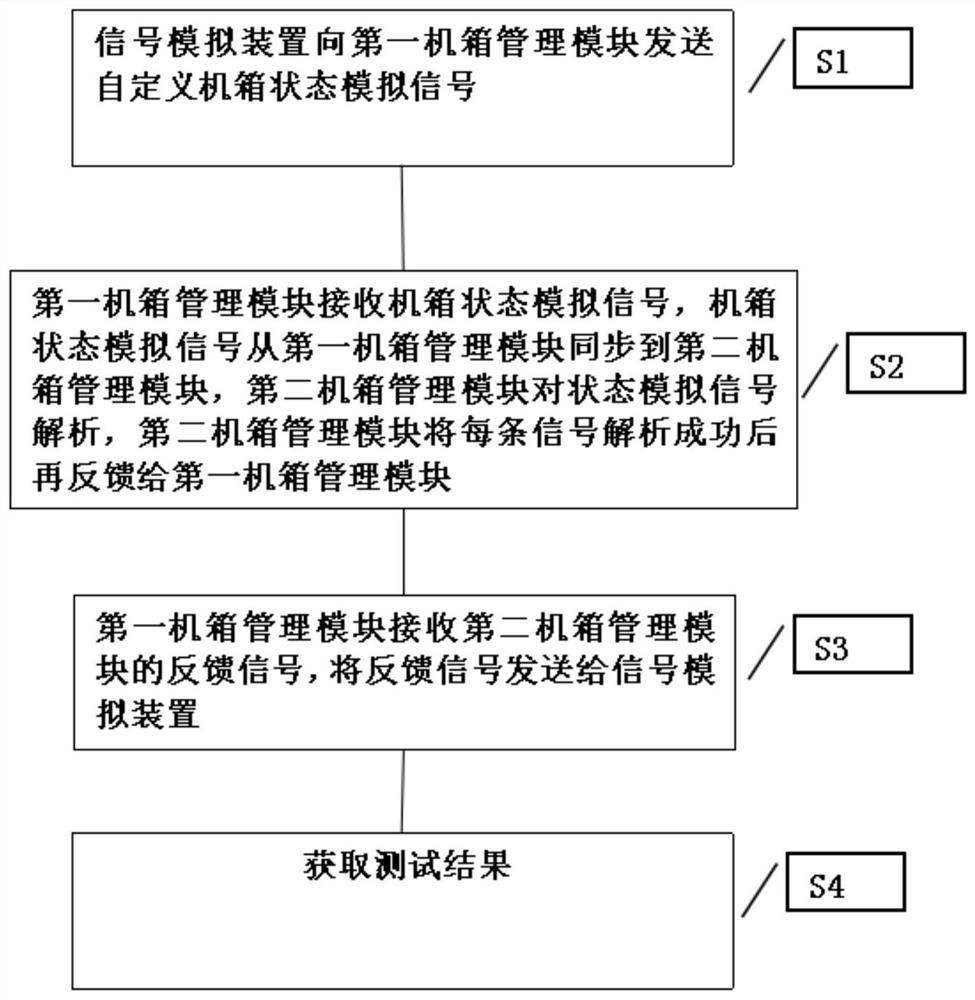

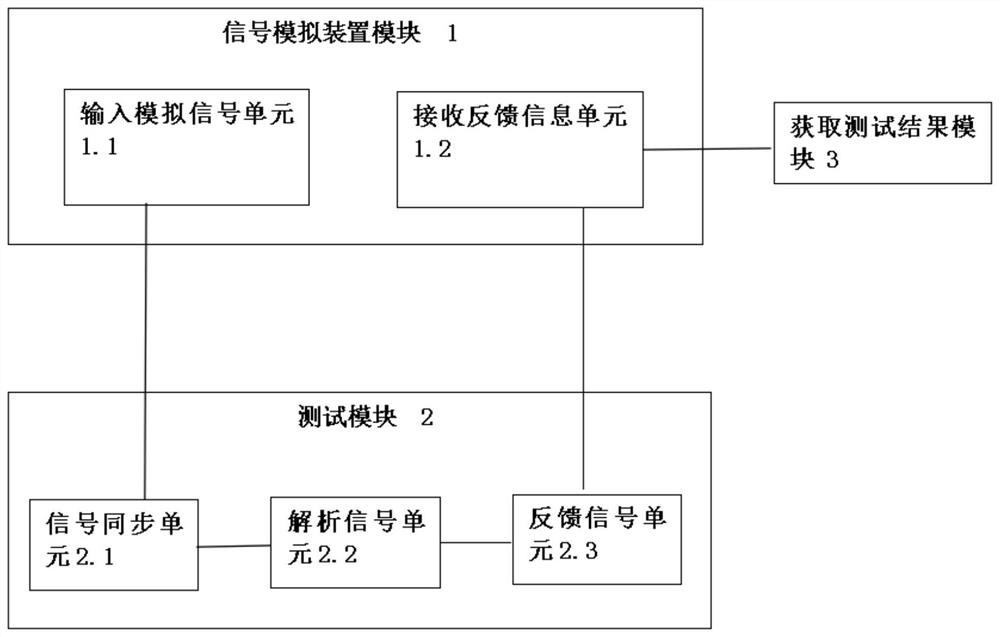

Test method and system for information synchronization between case management modules and storage medium

PendingCN112463496AEfficient and convenient testingImprove test efficiencyFaulty hardware testing methodsTest efficiencyAnalog signal

The invention relates to a test method for information synchronization between case management modules. The method comprises the following steps: S1, a signal simulation device sends a custom case state simulation signal to a first case management module; s2, the first case management module receives case state analog signals, the case state analog signals are synchronized to a second case management module from the first case management module, the second case management module analyzes the state analog signals, and the second case management module feeds back each signal to the first case management module after successfully analyzing each signal; s3, the first case management module receives a feedback signal of the second case management module and sends the feedback signal to the signal simulation device; s4: a test result is obtained. According to the invention, the test efficiency and the test accuracy are significantly improved, the physical loss of equipment is greatly reduced, and human resources are saved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

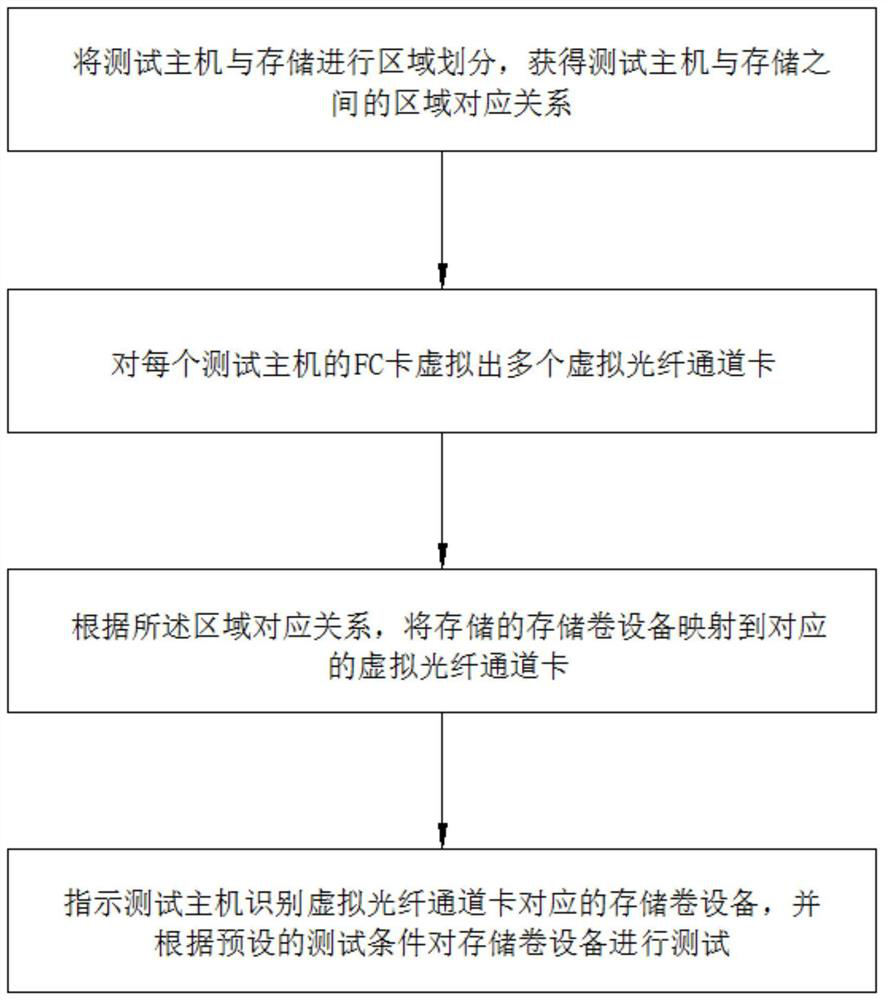

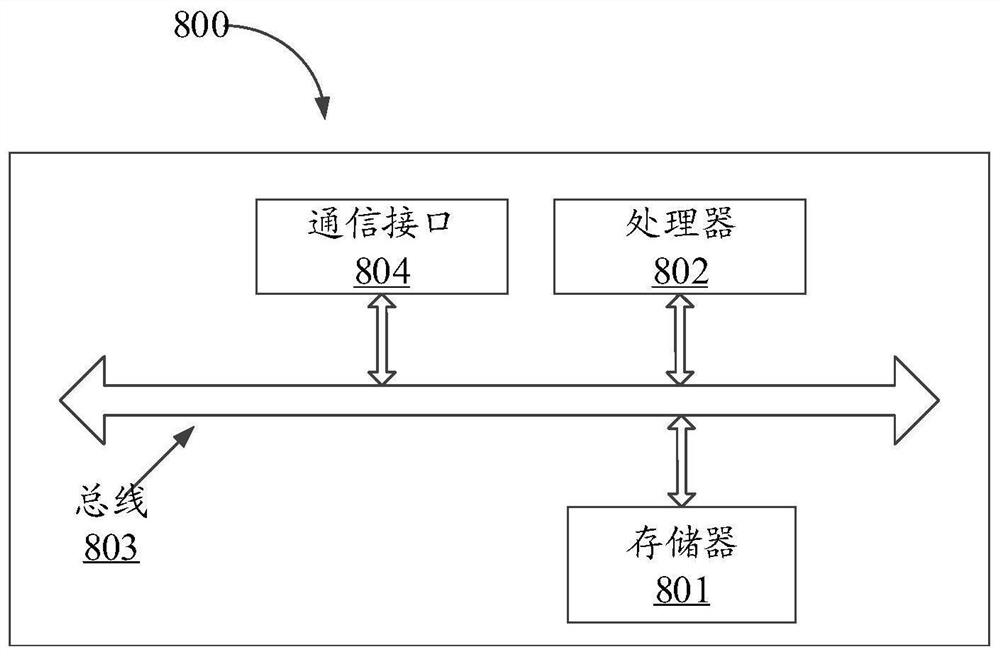

Storage test method and device and electronic equipment

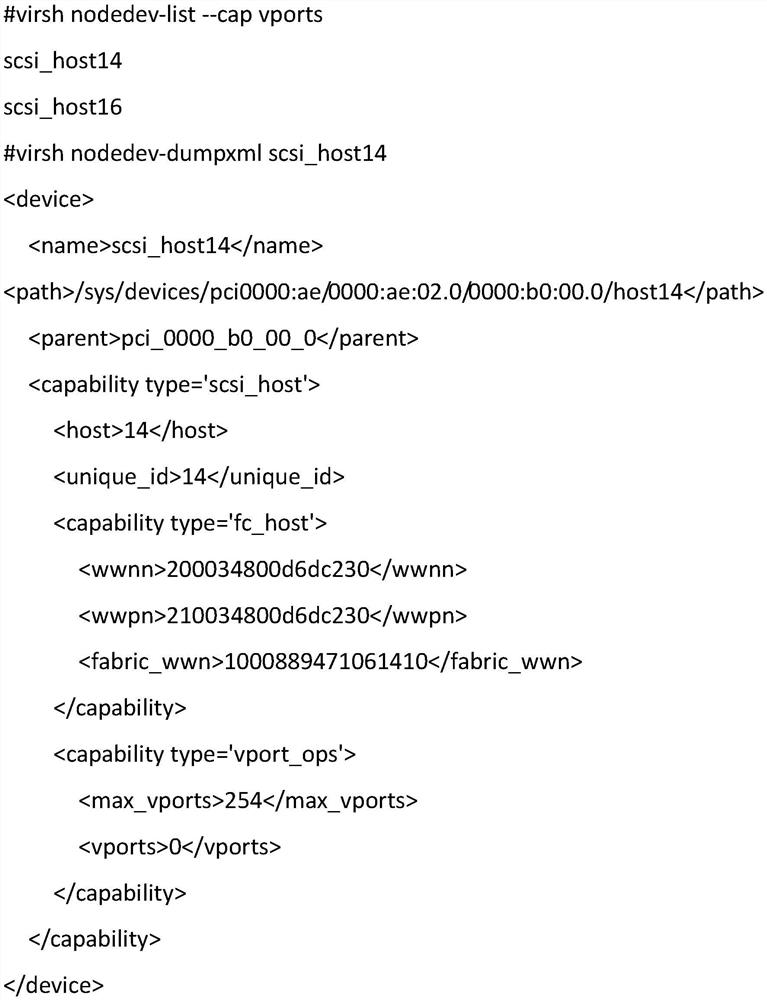

InactiveCN112433949AReduce test costSpeed up testingSoftware testing/debuggingEmbedded systemVirtualization

The invention provides a storage test method and apparatus, and an electronic device, belongs to the technical field of computers, and solves the problems that some storage functions are not easy to fully test and the automation degree is not high in an existing test technology. The method comprises the steps of performing region division on a test host and a memory to obtain a region corresponding relationship between the test host and the memory; virtualizing a plurality of virtual fiber channel cards for the FC card of each test host; mapping a stored storage volume device to a corresponding virtual fiber channel card according to the area corresponding relation; and indicating the test host to identify the storage volume device corresponding to the virtual fiber channel card. The FC virtualization technology is adopted, and a physical card is simulated into a plurality of virtual optical fiber channel cards. And each virtual optical fiber channel card is defined as a host at the storage end, so that the requirement of a test environment on the number of hosts is met. And meanwhile, automation of the test is realized by utilizing the characteristic of virtualization flexibilityof the FC card.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Intelligent track circuit shunt parameter tester and realization method thereof

InactiveCN106291317AGood effectIncrease contactCurrent/voltage measurementElectronic circuit testingElectricityCopper wire

The invention relates to an intelligent track circuit shunt parameter tester and a test method thereof. The intelligent track circuit shunt parameter tester comprises a hand-held tool that matches the shape of the surfaces of steel rails and a test instrument that is connected to a contact copper board of the hand-held tool via a copper wire. The hand-held tool has three parts, namely, an integrated outer sheath with a handle, the contact copper board with the same arc shape as the surface of the steel rails and a rust-removing filing board. The copper wire is led out from the contact copper board of the hand-held tool. The instrument is arranged in a customized housing. Two copper pillars are installed at the top of the housing and are connected to the copper wire on the back of the housing. After the instrument is mounted in the housing, shunt electrical signals can be effectively obtained through the two copper pillars, and calculation is automatically carried out according to the electric signals. The technical scheme provided by the invention can solve the problem of poor contact of the tester which may be caused due to corrosion of the steel rail, and the rail surface voltage between the two steel rails and the shunt current after the two steel rails are shunted can be measured efficiently and conveniently.

Owner:袁伟家

Test method for obtaining load factors of router and system thereof

The invention discloses a test method for obtaining load factors of a router in a BGP / MPLS VPN environment and a system thereof. The test method comprises the following steps: connecting a test instrument with a PE router in an MPLS / IP network; sending at least two test streams to the tested router by the test instrument, wherein, values of test parameters to be tested in each test stream are different, and other parameters are fixed; and recording link sharing condition in the stream output direction of the tested router, if traffic of the test stream can load sharing, judging the tested router can take the test parameters as the load factors for participating in load sharing calculation. By adopting the test method, the load factors on which the router performs VPN traffic load sharing can be conveniently and efficiently tested, and the effect for starting VPN traffic load sharing in a practical network traffic environment according to the obtained test results, which provides instruction opinions for deployment of the VPN traffic load sharing function of each equipment in a practical network, and the test results have greater reference value.

Owner:CHINA TELECOM CORP LTD

System and method for indoor vehicle engine exhaust brake testing

ActiveCN103134683BHigh precisionSimplify the collection processEngine testingDrive wheelExhaust brake

Owner:BEIQI FOTON MOTOR CO LTD

Blowing test system and blowing test method of dust remover

PendingCN111841175AEfficient and convenient testingQuick checkDispersed particle filtrationTransportation and packagingEngineeringMechanical engineering

The invention discloses a blowing test system of a dust remover and a blowing test method of the dust remover. An air bag can slide or be fixed along a stand column, a blowing pipe is arranged on an adjustable support part, and the distance between the blowing pipe and a filter bag mounting hole is adjusted through the up-and-down sliding of the support part; in practical testing, the distance between the blowing pipe and the filter bag mounting hole can be adjusted only by sliding the support part; meanwhile, the air bag can also slide along the stand column, the air bag can be fixed by adjusting the distance between the blowing pipe and the filter bag mounting hole, the blowing effects of the dust remover at different blowing distances can be rapidly detected without repeatedly detachingthe blowing pipe and the air bag, operation is easy, consumed time is short, and efficient and convenient testing of a blowing system is achieved.

Owner:HUANGSHI LIANGFENG MACHINERY

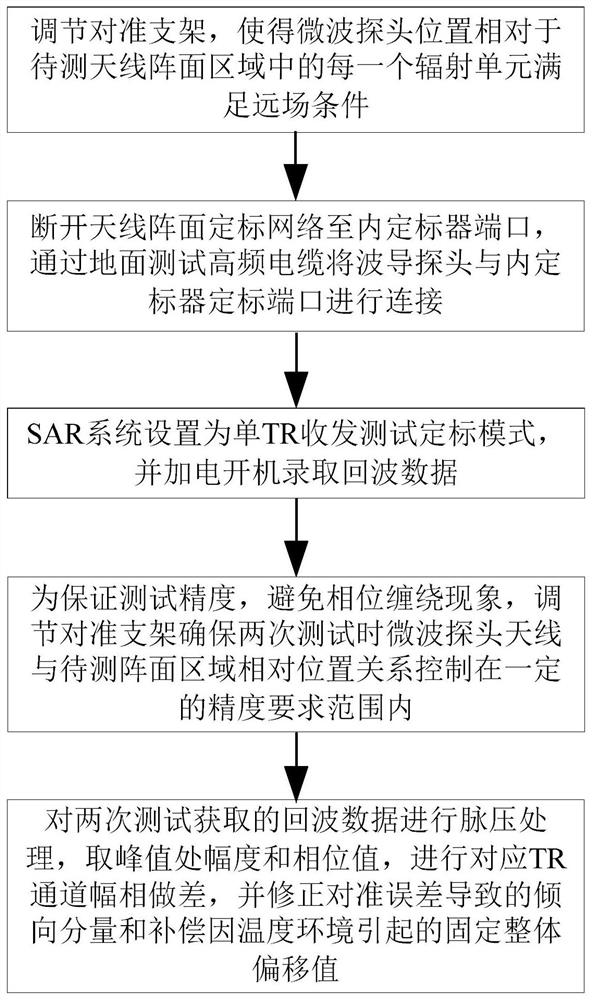

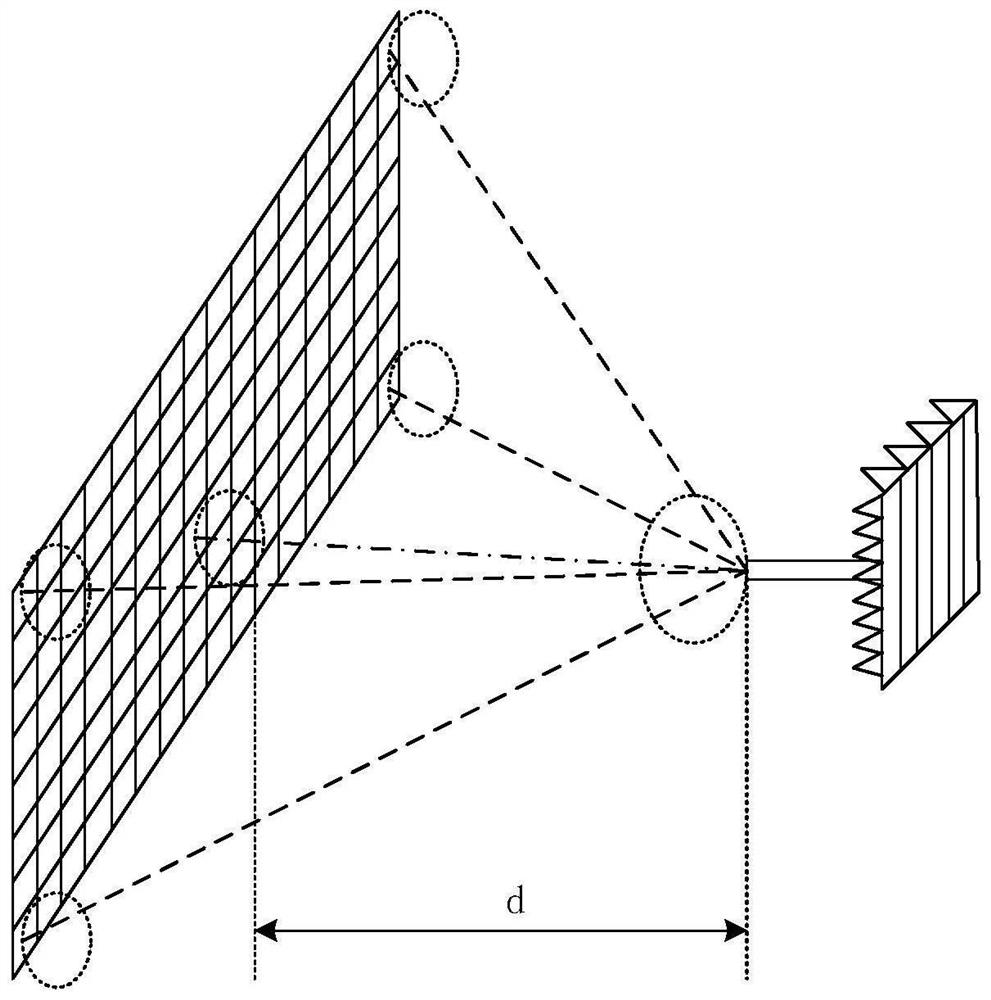

Amplitude and Phase Stability Test Method for Full Link of Active Phased Array System SAR Channel

ActiveCN111123221BEfficient and convenient testingShort timeRadio wave reradiation/reflectionGround testingElectric cables

The invention provides a method for testing the amplitude and phase stability of the full link of the active phased array system SAR channel, which ensures that the position of the microwave probe antenna used for testing meets the remote test conditions and is aligned with the selected antenna array point to be tested; Connect the antenna array calibration network to the port of the internal calibrator, and connect the internal calibrator port with the microwave probe antenna through the ground test with a high-frequency cable; set the spaceborne SAR system in the single TR test calibration mode and perform the whole satellite addition. Start the electric machine to record the echo data; perform pulse pressure processing on the echo data obtained from the previous two tests to obtain the amplitude and phase value at the peak value, perform amplitude and phase difference of the corresponding TR channel, and perform fixed tilt correction and fixed temperature offset value Compensation can get the amplitude and phase stability test results of each TR channel. It meets the requirements of the full-link amplitude and phase stability test of the SAR channel of the spaceborne active phased array system.

Owner:SHANGHAI SATELLITE ENG INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com