Full-automatic production equipment and full-automatic production method for slide switch

A technology for sliding switches and production equipment, applied in electrical switches, electrical components, circuits, etc., can solve the problems of easy falling of the slide, low success rate of spring feeding, and difficulty in feeding the upper cover, so as to improve the success rate , Increase the connection stability and avoid the effect of poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

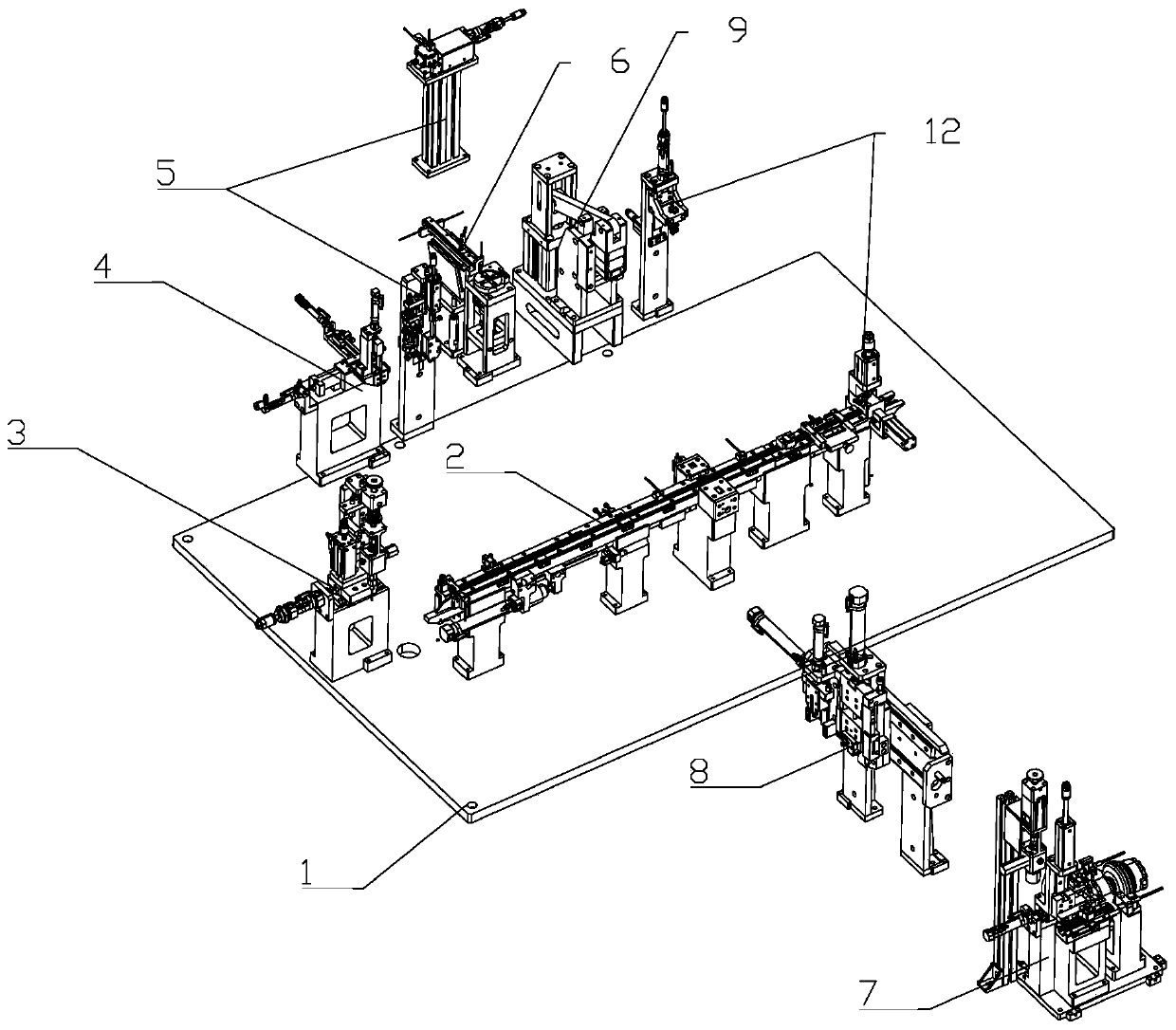

[0038] Such as figure 1 As shown, a sliding switch automatic production equipment includes a frame 1 and a feeding device 2 installed on the frame 1, a base positioning device 3, a handle feeding device 4, a spring feeding device 5, and a slide feeding device 6 , upper cover feeding device 7, synchronous handling device 8, pressing device 9 and test sorting device 12; described base positioning device 3, handle feeding device 4, spring feeding device 5, slide sheet feeding device 6, The pressing device 9 and the testing and sorting device 12 are sequentially arranged on the side of the feeding device 2, the synchronous conveying device 8 is located above the feeding device 2, the upper cover feeding device 7 and the synchronous conveying device 8 On the side, the synchronous conveying device 8 is located between the slide feeding device 6 and the upper cover feeding device 7 .

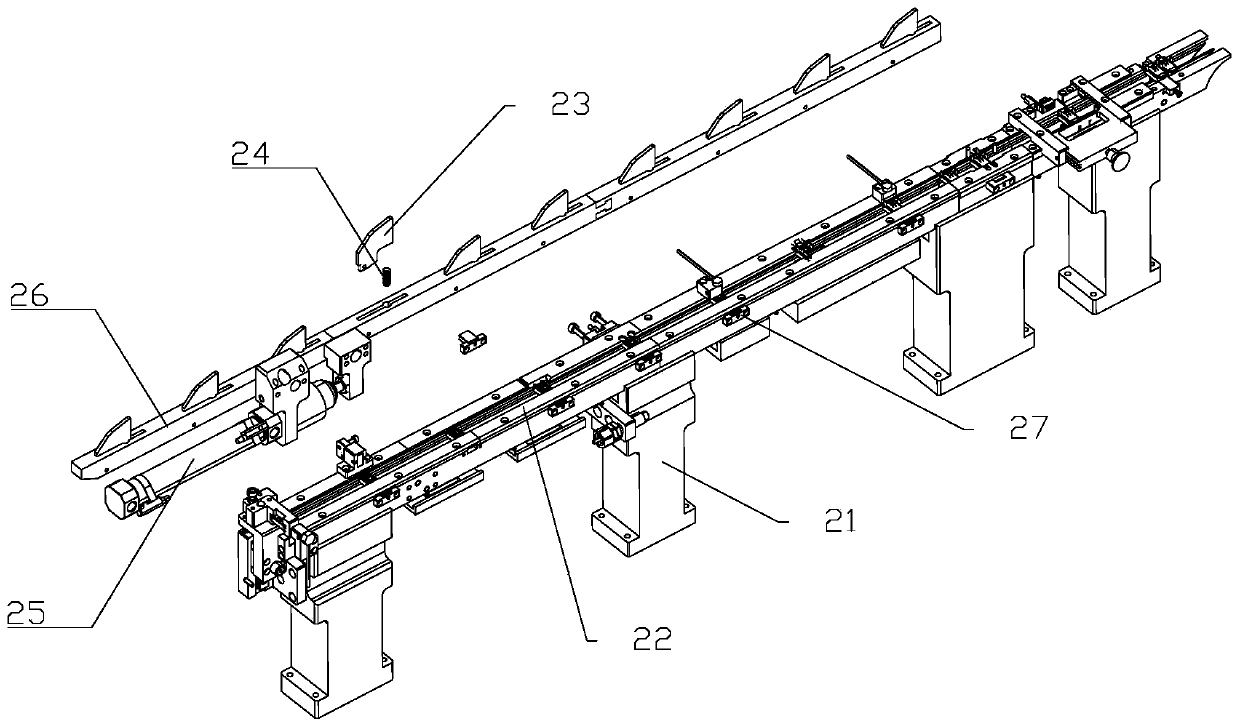

[0039] The material passing device 2 is used to realize the step-by-step feeding of the base. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com