Water pipe pressure testing machine

A pressure test and water pipe technology, which is used in the test of fluid tightness, the use of repetitive force/pulsation force to test the strength of materials, and the test of machine/structural components. Complex operation and other problems, to achieve the effect of intuitive and clear test process and results, convenient and fast test, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

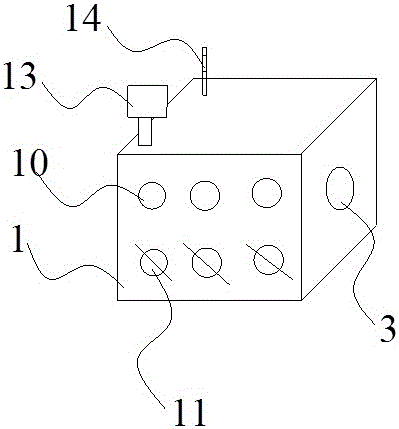

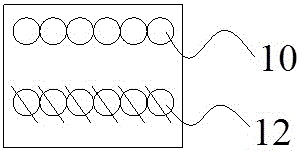

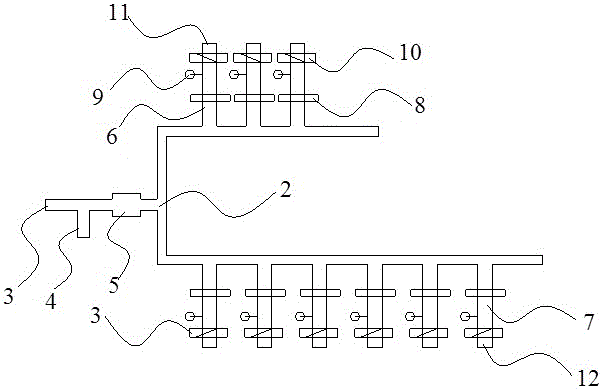

[0019] A water pipe pressure testing machine provided by the invention, such as figure 1 , figure 2 , image 3 As shown, it includes: a body 1 and a pressure pipeline 2. The pressure pipeline 2 is arranged in the body 1 and is provided with a gas inlet 3 for connecting a gas source. The gas inlet 3 is located on one of the outer surfaces of the body 1; the pressure pipeline 2 At the end of the gas inlet 3, an oil-water separator 4 and a gas regulating valve 5 are connected in series in sequence, and at the gas outlet of the gas regulating valve 5, it is divided into a parallel first pressure pipe branch and a second pressure pipe branch, and the oil-water separator 4 is used To separate oil droplets and water droplets with a density higher than that of compressed air, the gas regulating valve 5 is used to adjust the flow rate.

[0020] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com