Silver/silver chloride electrode applicable to deep sea and preparation method thereof

A silver chloride electrode, silver chloride technology, applied in the direction of electrochemical variables of materials, etc., can solve the problems of stuck, mold scrap, limited electrode production, etc., to achieve simple preparation process, not easy to be polarized, and strong reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

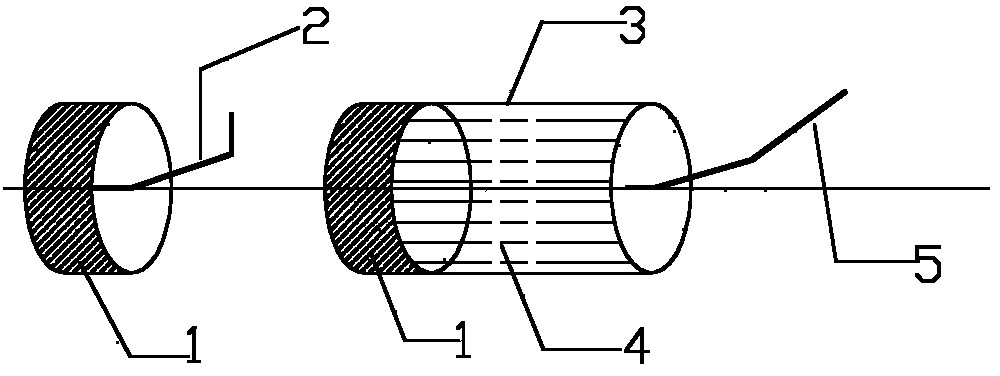

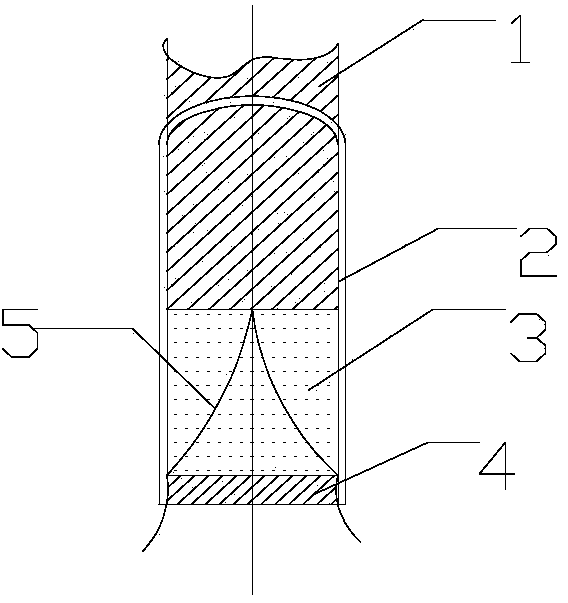

[0021] a. Prepare a 14cm-long viscose-based graphite fiber, fold it in half and follow figure 2 Arrangement shown is in mold, ready for use.

[0022] b. All subsequent processes will be operated in a dark room. According to the design life, weigh silver chloride and silver powder in a certain proportion, mix and grind them in an agate mortar until the color is uniform, then transfer the powder to a stirrer and stir it mechanically for 3 times , stirring for 1 min each time, with an interval of 3 min.

[0023] c. Transfer the mixed powder in step b to the mold, keeping the loose powder leads figure 2 state, apply a 2.5MPa force to the powder through a tablet press. When the pressure is stable, continue to apply it for 30s, then remove the pressure, and carefully take out the pressing piece with the lead wire in the mold.

[0024] d. Twist the copper wire and the lead wire together and fix them with conductive glue, cut out a PVC sleeve with a size of ¢4cm*3cm, and follow t...

Embodiment 2

[0027] a. Prepare a 14cm-long viscose-based graphite fiber, fold it in half and follow figure 2 Arrangement shown is in mold, ready for use.

[0028] b. All subsequent processes will be operated in a dark room. According to the size of the electrode required for the test, weigh silver powder and silver chloride particles in a certain proportion and put them into an agate mortar, mix and grind until the color is uniform, and then transfer the powder to the mixer. Stir mechanically 3 times, 1 min each time, with an interval of 3 min.

[0029] c. Then transfer the powder to the mold so that the lead wires of the loose powder remain figure 2 state, apply a 2.5MPa force to the powder through a tablet press. When the pressure is stable, continue to apply it for 30s, then remove the pressure, and carefully take out the pressing piece with the lead wire in the mold.

[0030] d. Twist the copper wire and the lead wire together and fix them with conductive glue, and cut out a PVC s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com