Automatic detection device of vibrating screen square girder

An automatic detection and sieve square technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as the inability to realize automation, achieve reduced manual labor, good motion stability, and improve repeatability effect on accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

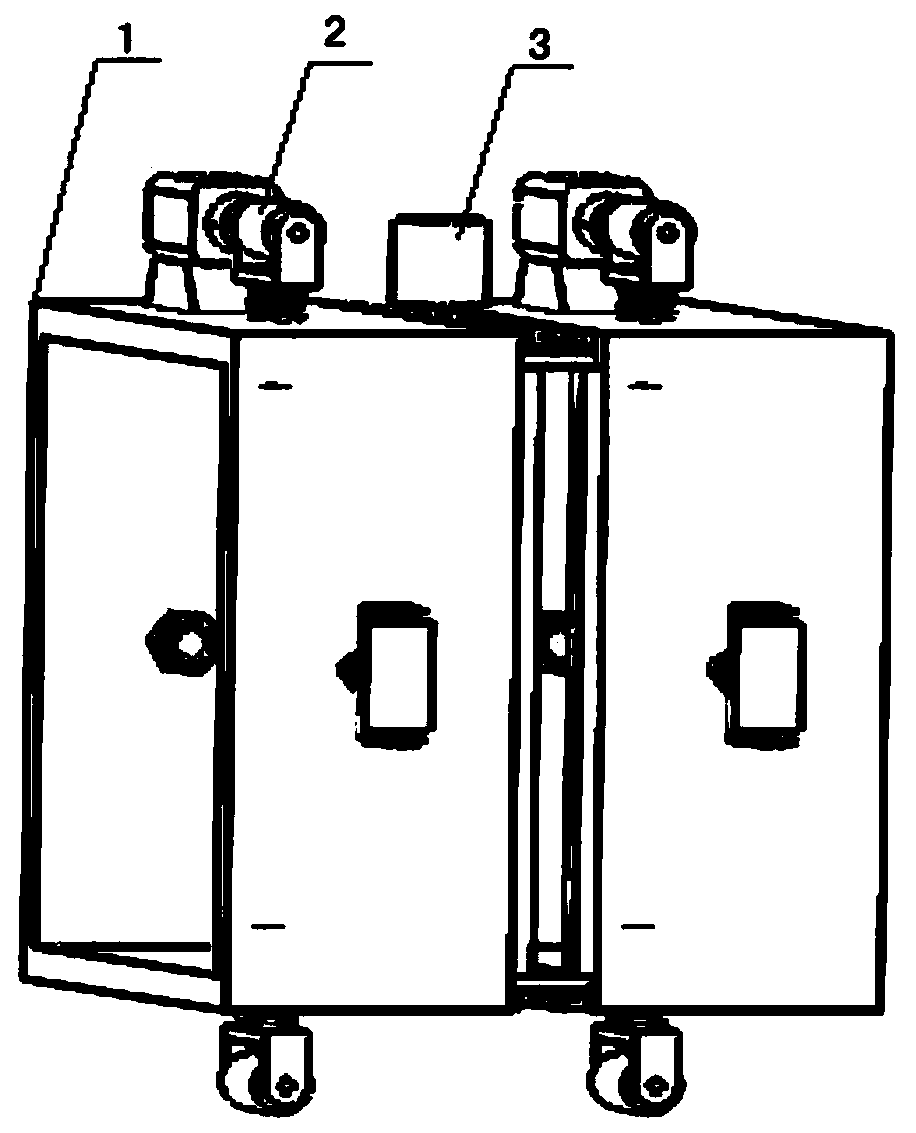

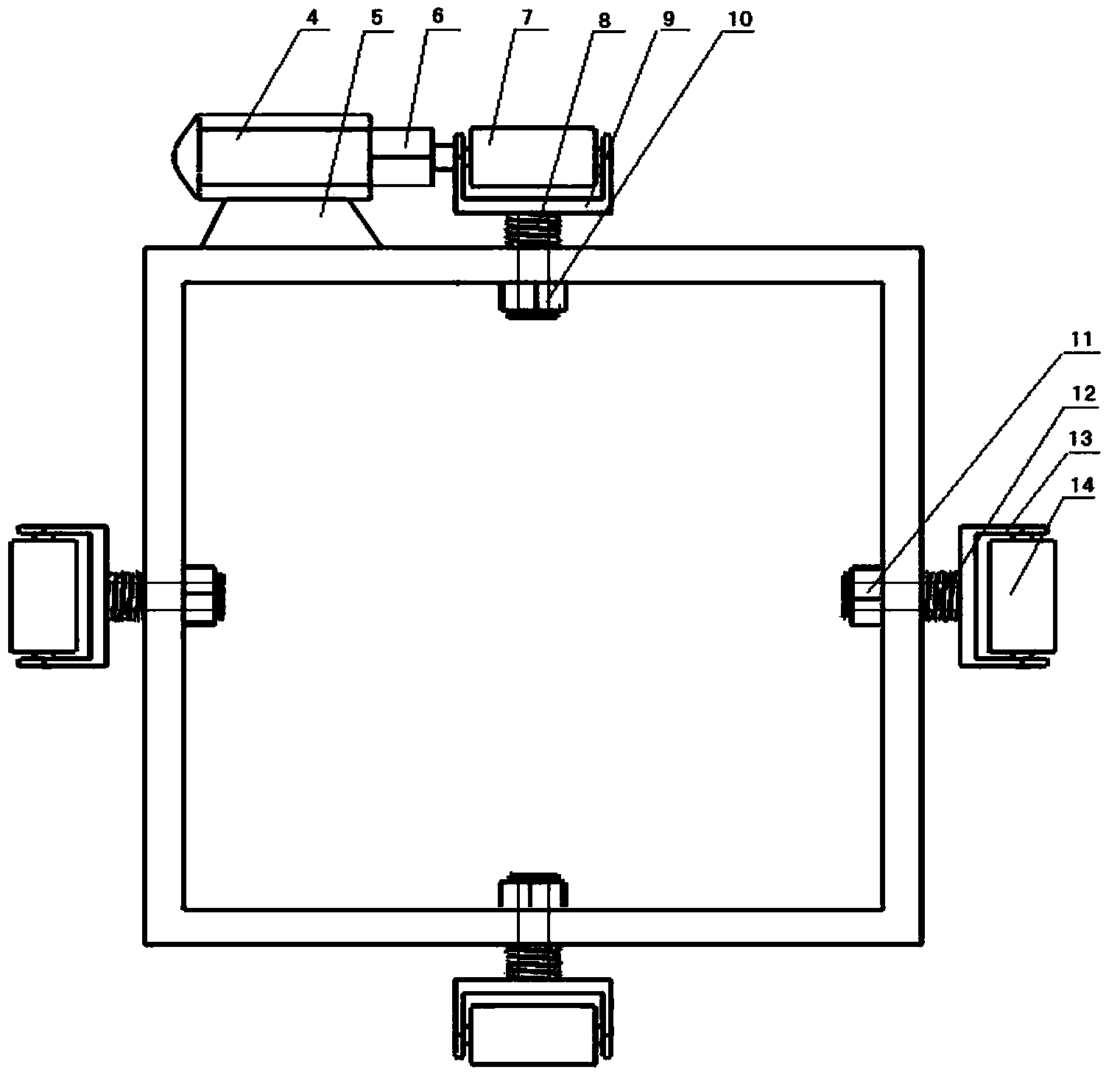

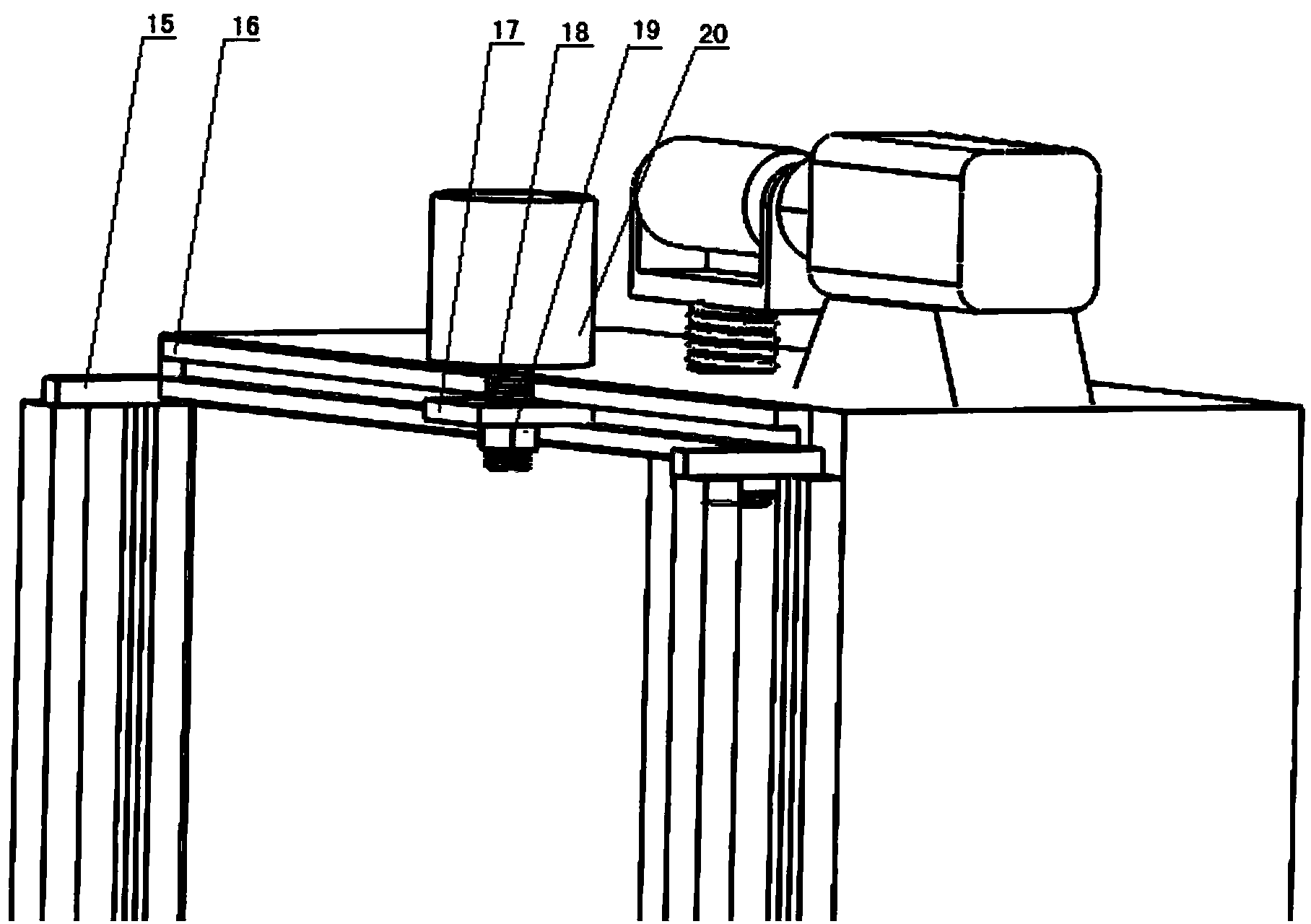

[0015] Such as Figure 1-3 As shown, an automatic detection device for a square girder of a vibrating screen, the device includes a bracket 1, an axial movement system 2, and a circumferential rotation system 3; the axial movement system 2 is composed of an active traveling mechanism and a driven traveling mechanism, Active traveling mechanism comprises motor 4, motor seat 5, speed reducer 6, driving wheel 7, driving wheel frame 9, spring one 8, nut one 10; Driven traveling mechanism comprises driven wheel 14, driven wheel frame 13, spring two 12. Nut 2 11; the circumferential rotation system includes a connecting plate 15, a track 16, a sensor seat 17, a tension spring 18, an adjusting nut 19, and a sensor box 20.

[0016] Specifically, the axial movement system 2 and the circumferential rotation system 3 are both fixedly connected to the support 1; the cross section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com