Disc brush motor detecting station

A detection platform and disc brush technology, applied in the field of mechanical experiments, can solve the problems of reducing the service life of the disc brush, the loss of the motor of the disc brush, and the lack of testing equipment, etc., and achieve the effect of preventing wear and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

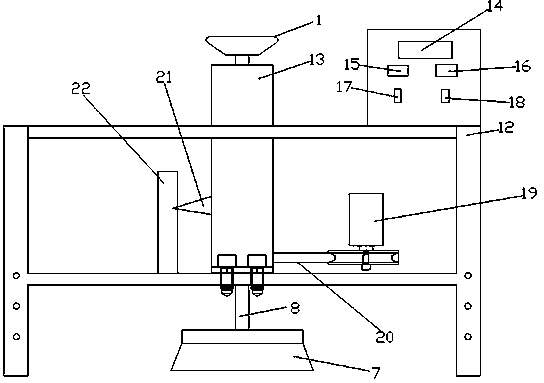

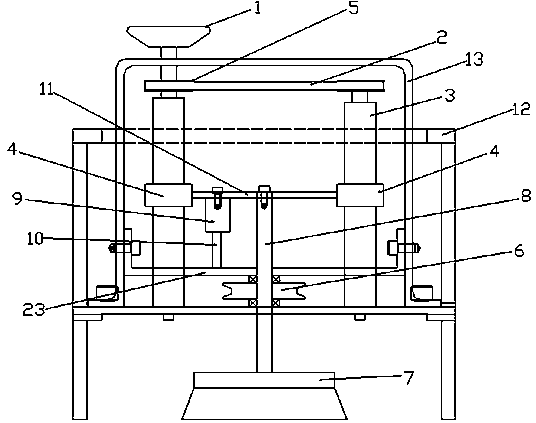

[0016] combine figure 1 and figure 2 Show the specific embodiment of a kind of disk brush motor detection platform of the present invention: a kind of disk brush motor 19 detection platform, comprise the bracket 12 that is built-in with the support plate parallel to the horizontal plane, be arranged on the disk brush adjustment device on the support plate, set The disc brush motor 19 on the support plate, and the detection device arranged on the bracket 12, the disc brush motor 19 is connected with the disc brush adjusting device through the belt 20, and the disc brush connected with the disc brush adjusting device is provided at the bottom of the bracket 12 7. The disc brush adjustment device is provided with a pressure sensing device, and the detection device is connected with the pressure sensing device and the disc brush motor 19 respectively.

[0017] The disk brush adjustment device includes a fixed screw rod bracket 13 arranged on the support plate, two lifting screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com