Clearance compensation mechanism of gas-pressure plate type brake

A disc brake and clearance compensation technology, applied in the direction of slack adjusters, etc., can solve the problems of increased manufacturing cost, complex structure, and difficult assembly by workers, and achieve the effects of guaranteed service life, simple mechanism, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

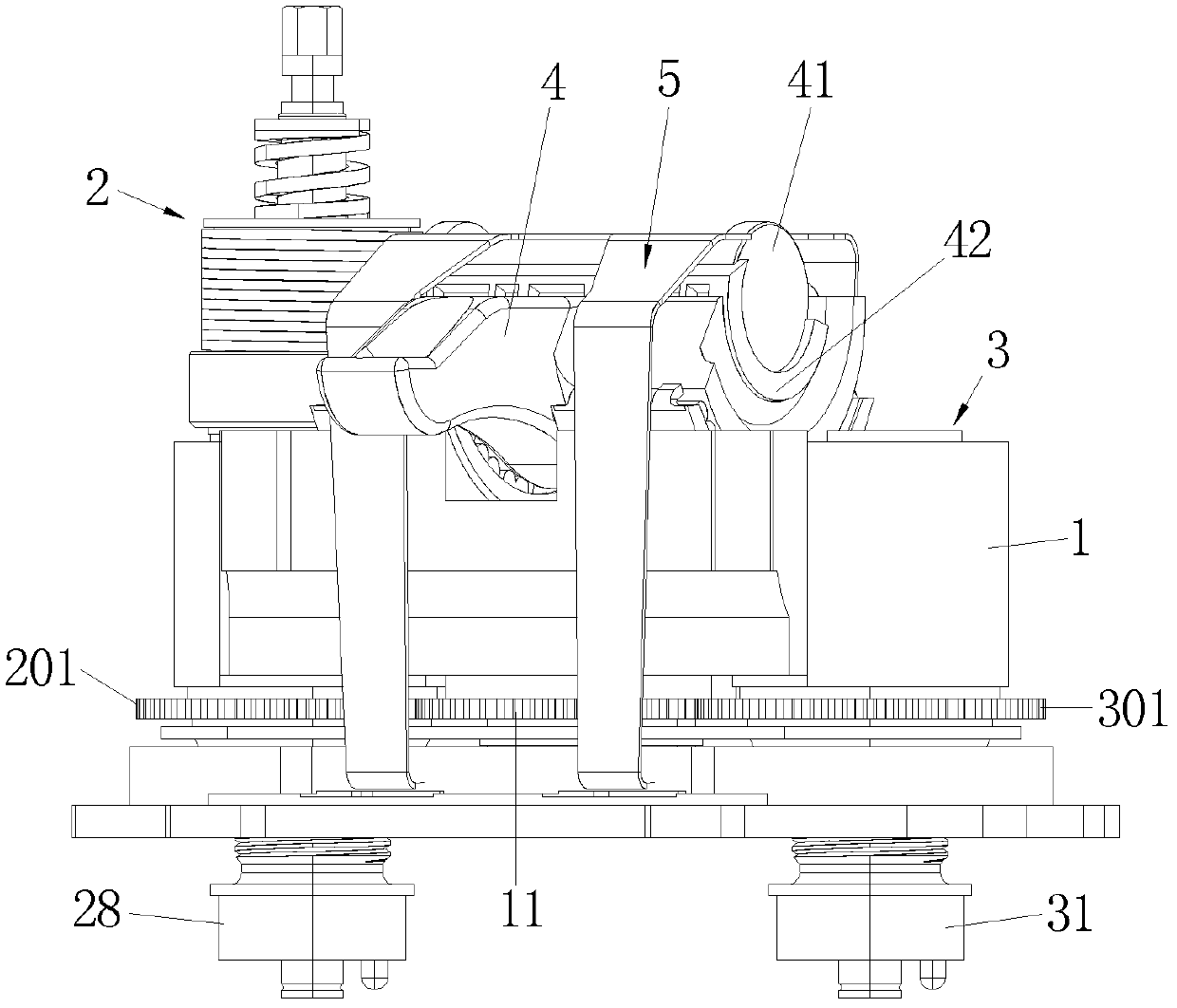

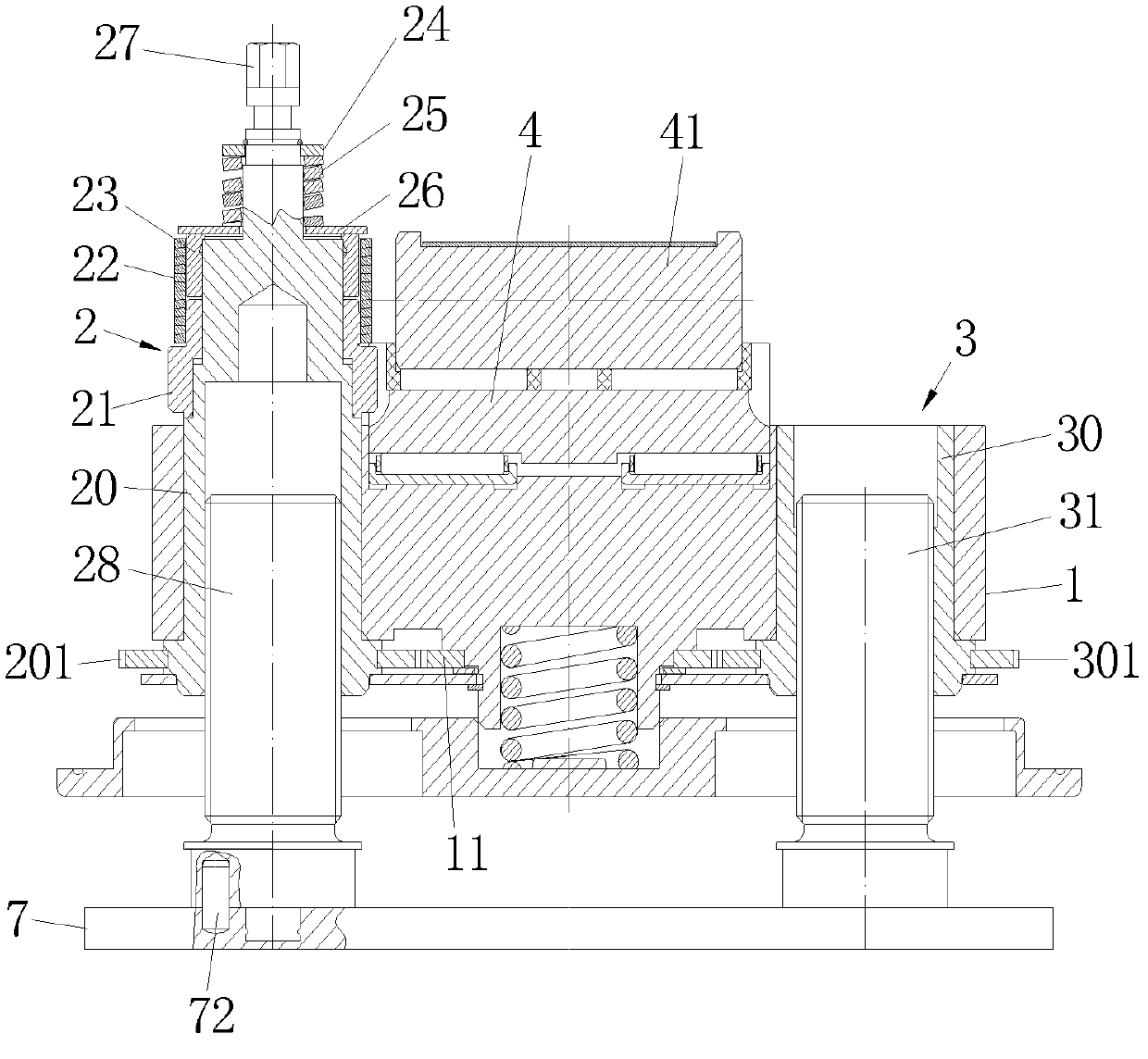

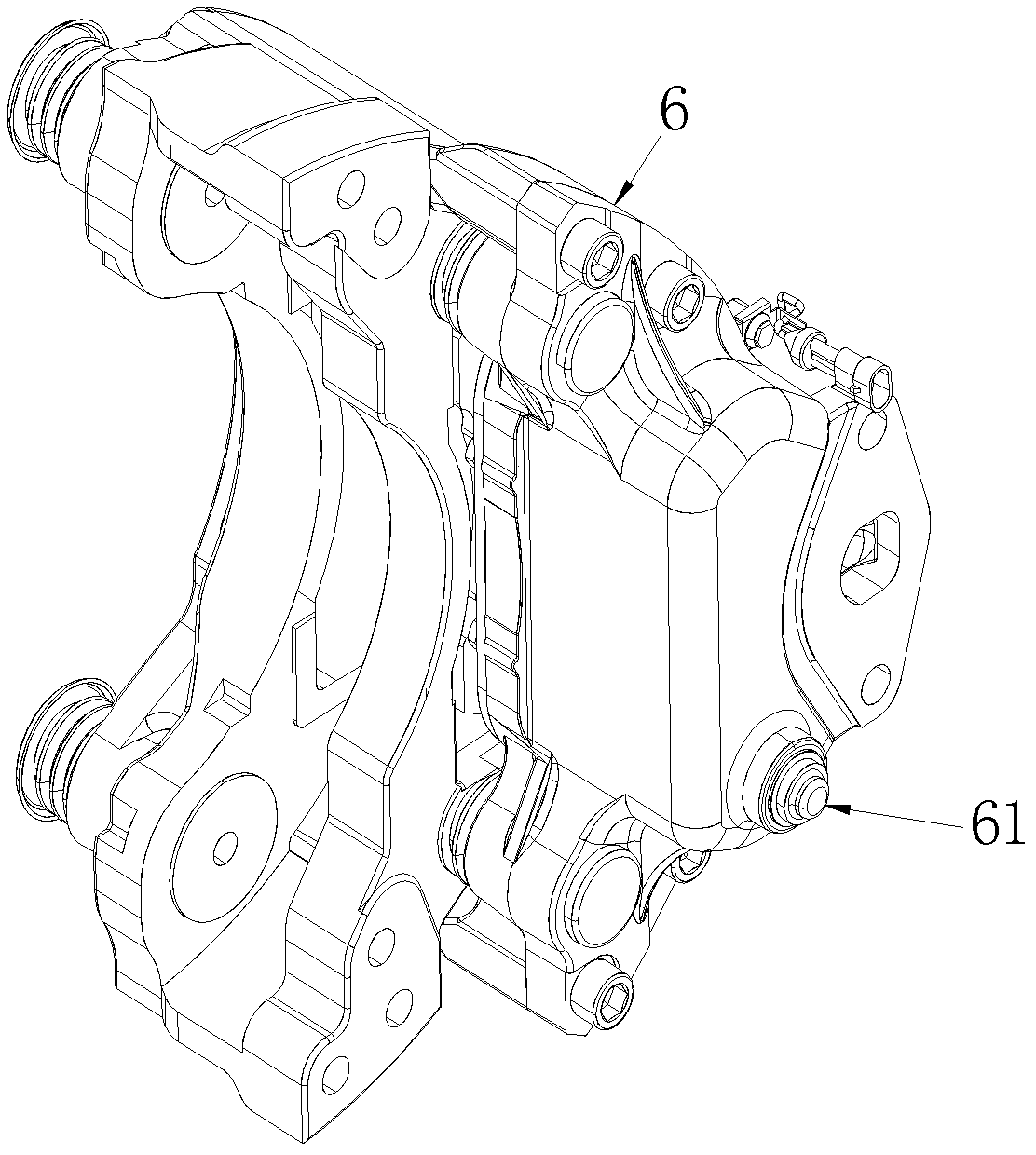

[0026] refer to Figure 1-4 , a gap compensation mechanism for an air pressure disc brake, comprising a booster mechanism, a support base 1, an active adjustment mechanism 2 and a driven adjustment mechanism 3 arranged at both ends of the support base 1, and connecting the active adjustment mechanism 2 and the driven adjustment mechanism 3 The transmission structure, the push plate 7 jointly driven by the active adjustment mechanism 2 and the driven adjustment mechanism 3; the active adjustment mechanism 2 includes a drive shaft assembly rotatably connected to one end of the support base 1 and an adjustment sleeve movably sleeved on the drive shaft assembly 21. The booster mechanism drives the active adjustment mechanism 2 to act while driving the support base 1 forward. Through the transmission of the transmission structure, the driven adjustment mechanism 3 and the active adjustment mechanism 2 operate synchronously to push the push plate 7 to complete the gap compensation. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com