A stress-digesting plastic pipe inside

A plastic pipe, stress relief technology, applied in the direction of pipes, pipe components, rigid pipes, etc., can solve the problems of poor digestion and absorption capacity, inconvenient installation and disassembly, and troublesome installation, and achieve convenient replacement, convenient transportation, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

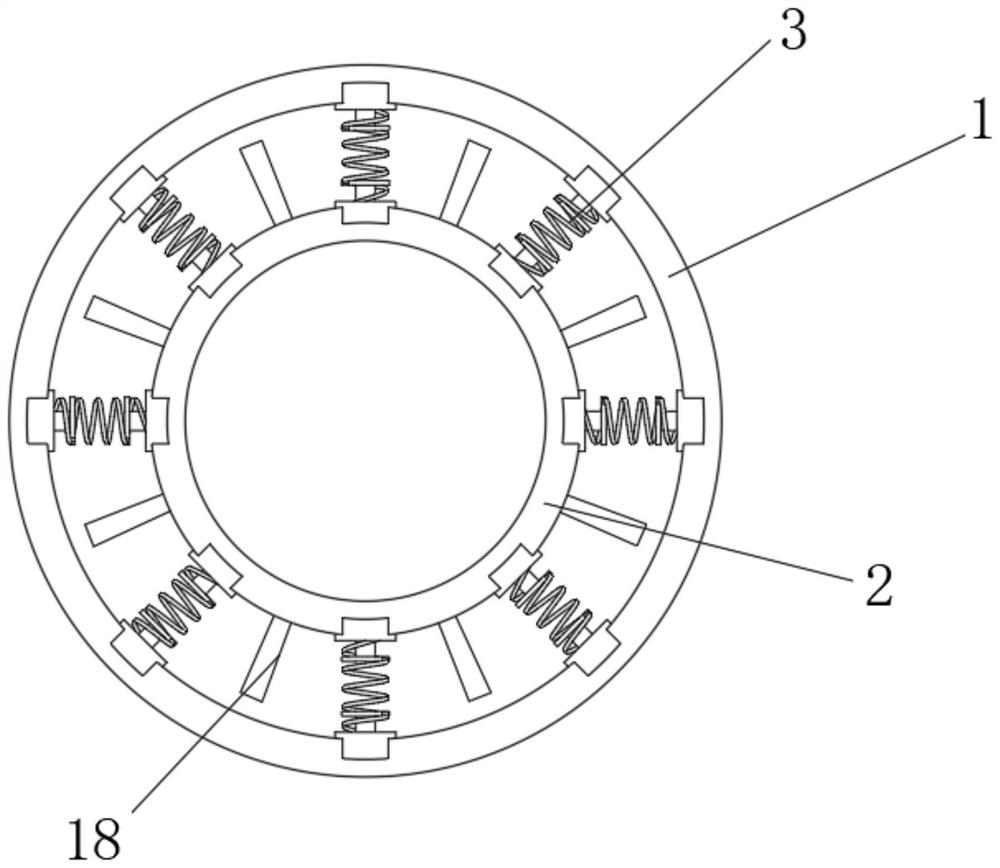

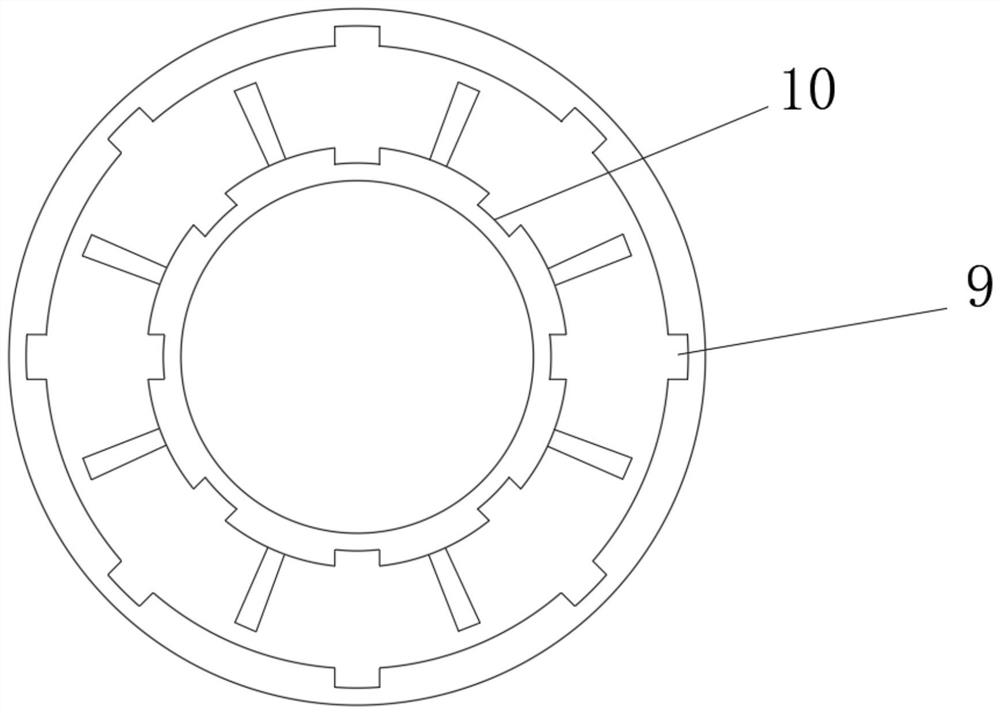

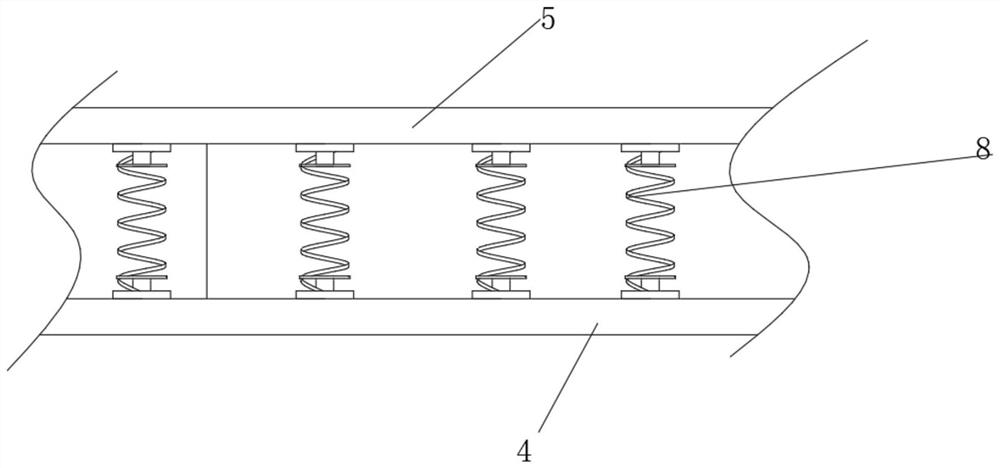

[0030] A kind of stress-digesting plastic pipe, in order to solve the problem of inconvenient and cumbersome installation in the fixed position and transportation of the pipe that digests and absorbs the stress that appears at present, as a preferred embodiment, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, it includes an outer pressure-bearing pipeline 1 and an inner stress-bearing pipeline 2, and a stress relief device 3 is provided between the outer pressure-bearing pipeline 1 and the inner stress pipeline 2, and the stress relief device 3 includes an outer fixing strip 4 and an inner fixing strip 5 , a buffer spring 8 is arranged between the outer fixing bar 4 and the inner fixing bar 5, an outer fixing bar groove 9 is opened inside the outer pressure-bearing pipeline 1, an inner fixing bar groove 10 is opened on the outer surface of the inner stressed pipeline 2, and an outer fixing bar groove 10 is opened on the outside All be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com