Method for installing stator blade fixing cover and device using the same

A technology for installing a stator and a fixed cover, which is applied to the supporting elements, stators, and engine elements of the blades, etc., can solve the problems of high labor consumption, small tolerances of holes and rivets, and damage of fixed rivets and fixed blades, and achieves high accuracy and avoidance. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

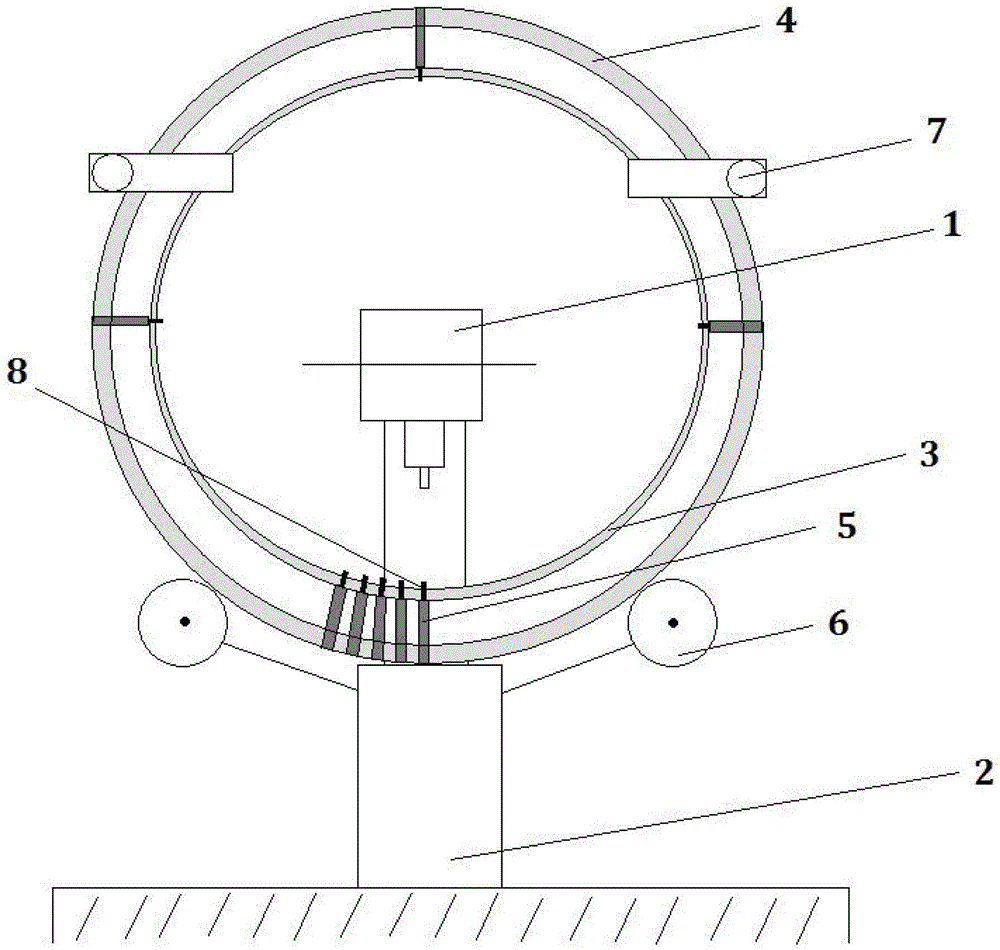

[0009] The method for installing the fixed cover of the stator blade is to insert the blade 5 into the blade wheel 4 freely without any fixing. The actual blade wheel 4 is located laterally on the rotating part 6 and is laterally fixed by the top 7 , while its bottom rests on a solid surface 2 . Simultaneously with the insertion of the blade 5 into the blade wheel 4 , the rivet 8 of the blade 5 is inserted into the shroud 3 so that the blade is supported on the solid surface 2 . The blade is fixed in the shroud 3 by moving the rivet 8 using the rivet head 1 . When the task is completed, the whole blade wheel 4 is rotated by means of the rotating part 6 to install the next rivet 8 . This method is applied until all blades 5 are fixed inside the shroud 3 .

example 2

[0011] The device for implementing the method of mounting the stator blade fixing cover consists of a non-indicative frame with a rotating part 6 mounted on the cover and a top 7 for fixing the blade wheel 4 so that its bottom is always perpendicular to the inserted blade 5 on the solid surface 2 . The rivet head 1 is located in the inner annular housing region 3 .

example 3

[0013] The bladed wheel 4 is placed on the rotating part 6 and on the solid surface 2 . Make sure it goes sideways through the top 7. The blade 5 is inserted into the blade wheel with the rivet 8 towards the center of the wheel. The rivets 8 of the prepared blade 5 are inserted in this way into the holes of the cover 3 prepared in advance. The rivet head 1 is located in the inner area of the blade wheel 4 , and indeed in the inner area of the shroud 3 , the movement of the rivet 8 causes the deformation to fix the shroud to the blade 5 . The blade 5 in this application sits on a solid surface 2 together with the blade wheel 4 on which the blade wheel 4 sits directly. This way, the least amount of dissipative energy transfer is used. In addition, the entire blade wheel is rotated by means of the rotating part 6, in this way the next blade is mounted. Apply this until all blades are secured. When this process is complete, the blade wheel 4 is removed and a number of bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com