Optical cable

An optical cable and optical fiber technology, applied in the directions of optics, light guides, optical components, etc., can solve the problems of increased transmission loss, damage to the flexibility of optical cables, etc., and achieve the effect of preventing the increase of transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0084] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to the following examples.

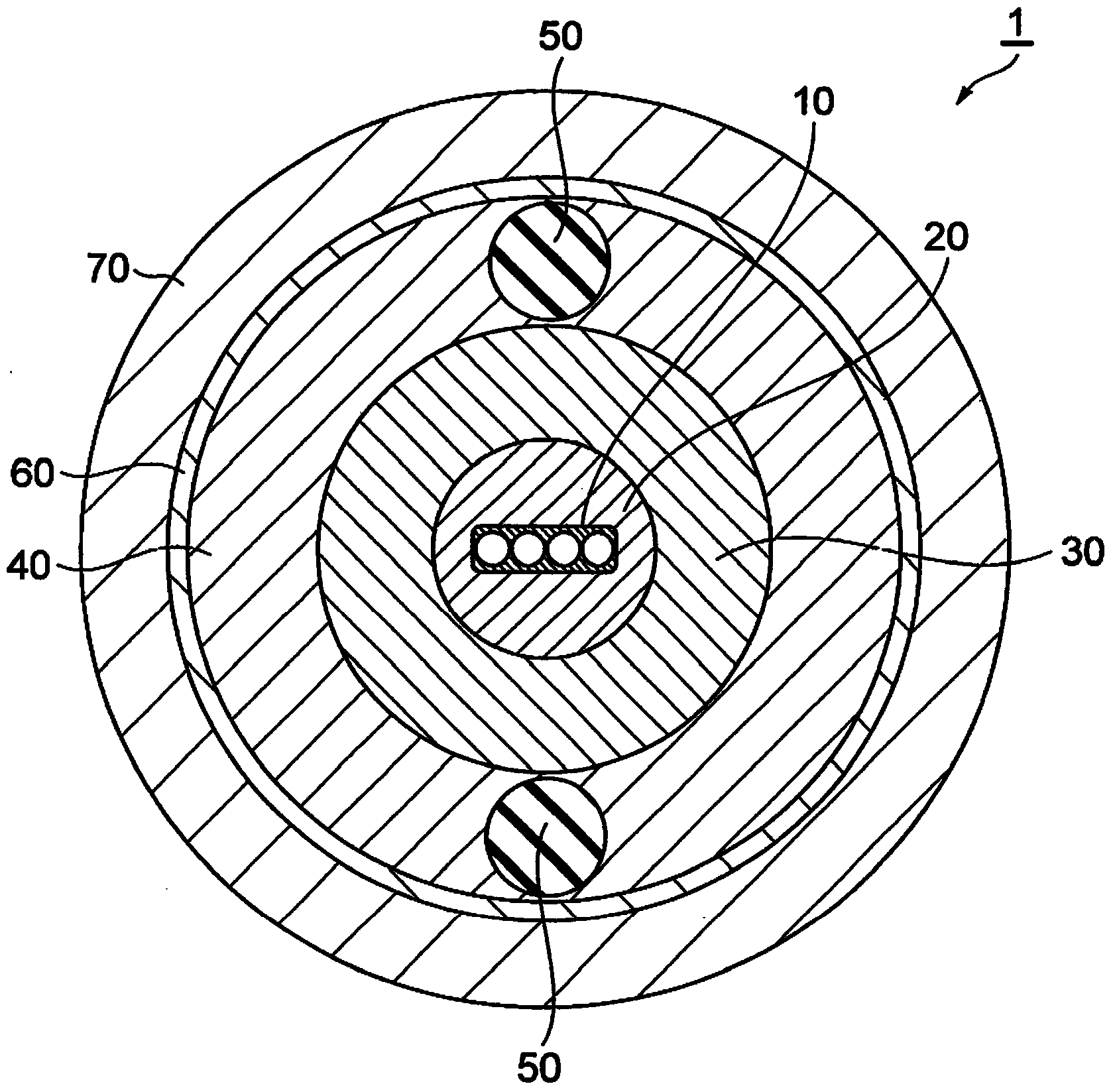

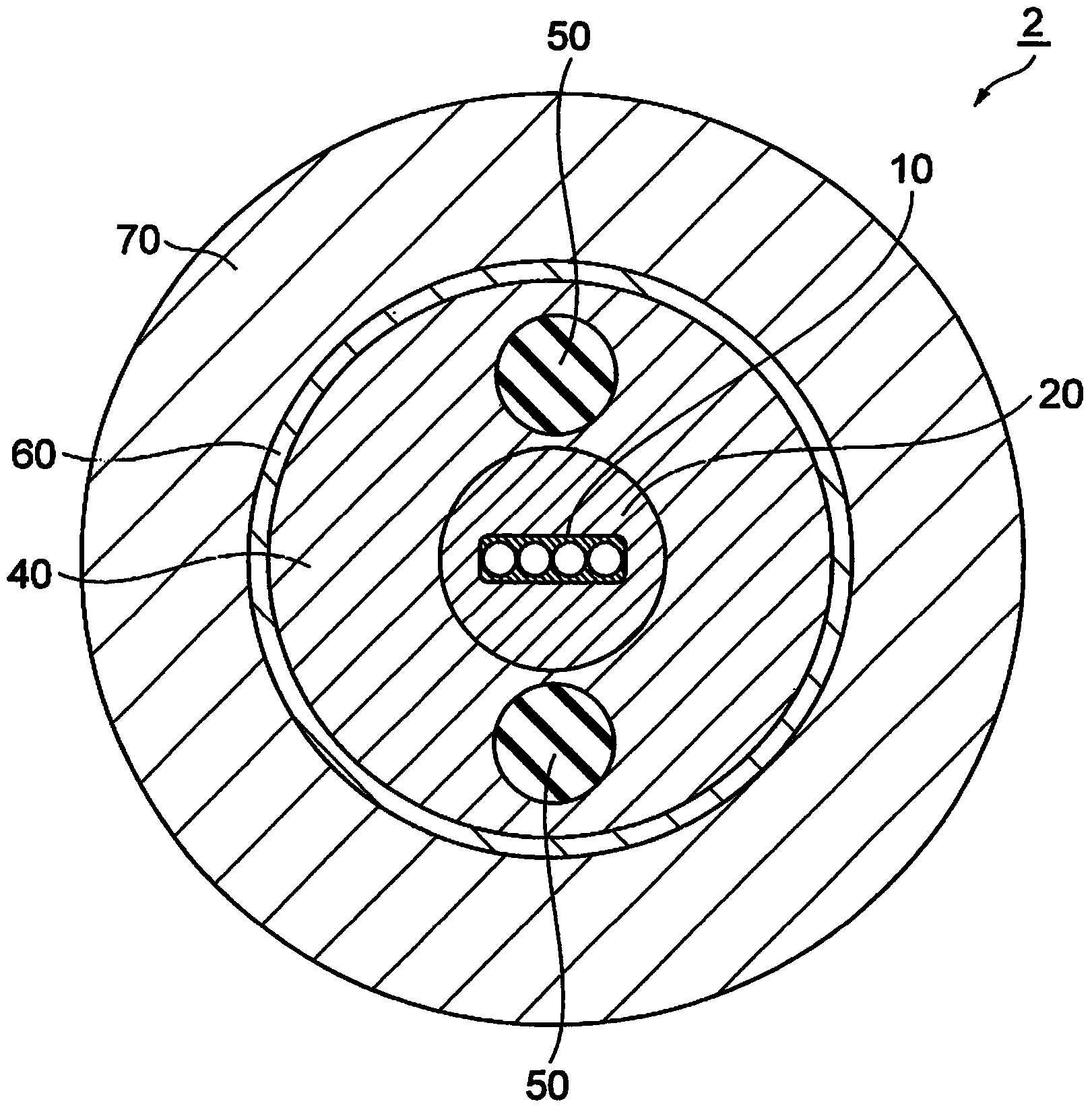

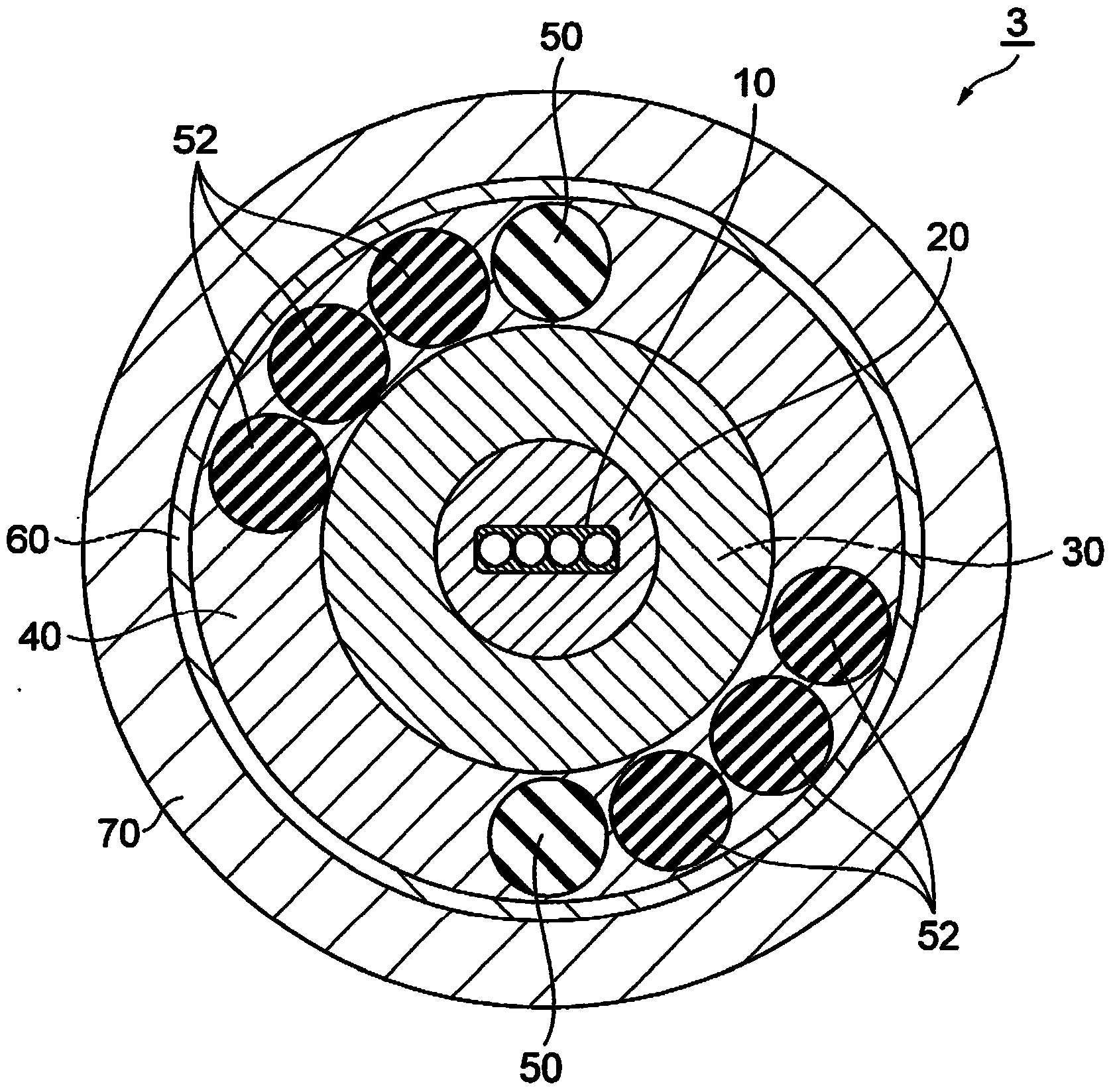

[0085] First, as Examples 1 to 10 and Comparative Example, manufactured Figure 12 fiber optic cable under the conditions shown. Figure 12 The optical cable constructions A-1 to A-5 shown in Figures 1 to 5 Corresponds to the construction of cables 1 to 5 shown in . in addition, Figure 12 The optical fiber structures B-1 to B-5 shown in Figure 6 to Figure 10 Corresponding to the configuration of the optical fiber ribbons 10A to 10E shown in , the specific diameters are as Figure 13 shown. In addition, in the optical cable of the comparative example, the sheath and the braid were not substantially in close contact and were not integrated. By the method described above, the pull-out force and adhesion force of the sheath and the braid were obtained.

[0086] Then, with respect to the optical cables accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com