Color filter substrate with touch function, manufacturing method thereof, and embedded touch screen

A technology of color film substrate and touch function, which is applied in the field of flat panel display, can solve the problems of poor electrical connection effect, and achieve the effect of preventing the detection line from being unable to connect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

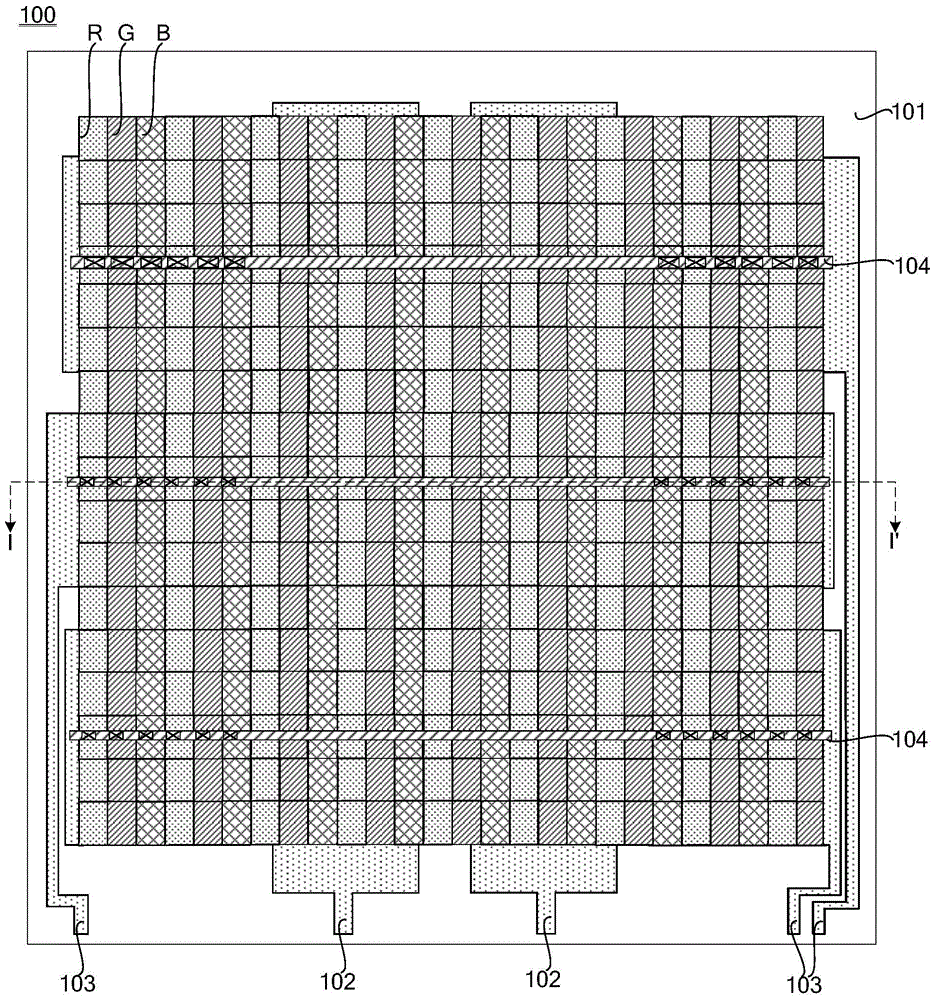

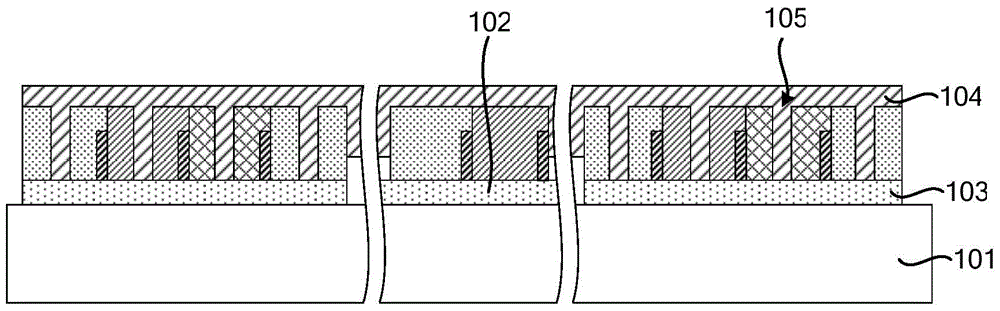

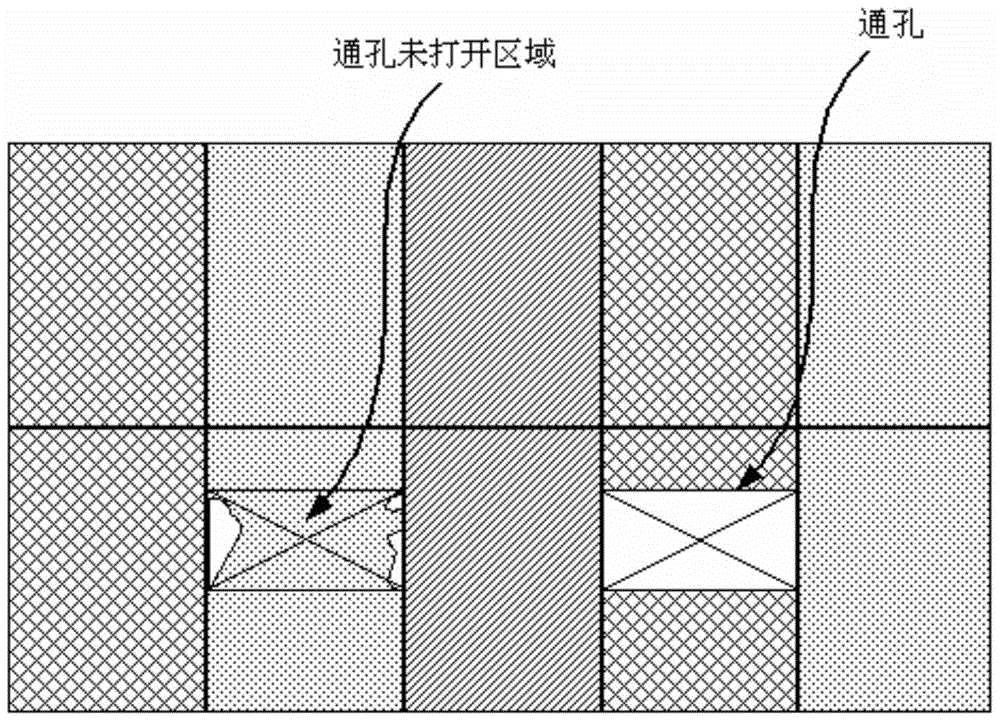

[0063] Please refer to Figure 4 and Figure 12 , which is a schematic structural diagram of a color filter substrate with a touch function according to Embodiment 1 of the present invention. Such as Figure 4 and Figure 12 As shown, the color filter substrate 200 with touch function includes: a substrate 201, a plurality of driving lines 203a, a plurality of detection lines 203b and a plurality of color resist layers; wherein, the plurality of driving lines 203a and the plurality of detection lines Lines 203b are formed on the substrate 201, the driving lines 203a and detection lines 203b are arranged in a criss-cross pattern and are independent of each other, and each detection line 203b is divided into several segments by the driving lines 203a; the plurality of color resist layers include A bottom color-resist layer and a top-layer color-resist layer, the bottom color-resist layer covers a part of the cut-off detection line 203b, and the part of the cut-off detection l...

Embodiment 2

[0095] Please refer to Figure 15 and Figure 16 , which is a schematic structural diagram of a color filter substrate with a touch function according to Embodiment 2 of the present invention. Such as Figure 15 and Figure 16 As shown, the color filter substrate 300 with touch function includes: a substrate 301, a plurality of driving lines 303a, a plurality of detection lines 303b and a plurality of color resist layers; wherein, the plurality of driving lines 303a and the plurality of detection lines Lines 303b are formed on the substrate 301, the driving lines 303a and detection lines 303b are arranged in a criss-cross pattern and are independent of each other, and each detection line 303b is divided into several segments by the driving lines 303a; the plurality of color resist layers include A bottom color-resist layer and a top-layer color-resist layer, the bottom color-resist layer covers a part of the cut-off detection line 303b, and the part of the cut-off detection...

Embodiment 3

[0114] Please refer to Figure 18 , which is a cross-sectional view of a color filter substrate with a touch function according to Embodiment 3 of the present invention. Such as Figure 18 As shown, the color filter substrate 400 with touch function includes: a substrate 401, a plurality of driving lines 403a, a plurality of detection lines 403b and a plurality of color resist layers; wherein, the plurality of driving lines 403a and the plurality of detection lines Lines 403b are formed on the substrate 401, the driving lines 403a and detection lines 403b are arranged in a criss-cross pattern and are independent of each other, and the detection lines 403b are divided into several segments by the driving lines 403a; the plurality of color resist layers include A bottom color-resist layer and a top-layer color-resist layer, the bottom color-resist layer covers a part of the cut-off detection line 403b, and the part of the cut-off detection line 403b not covered by the bottom co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com