A cement prefabricated splicing installation part

A technology of splicing parts and mounting parts, which is applied in the direction of construction and building construction, can solve problems such as inability to splice cement splicing parts, problems, cracks in cement splicing parts, etc., and achieve the effect of avoiding low connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

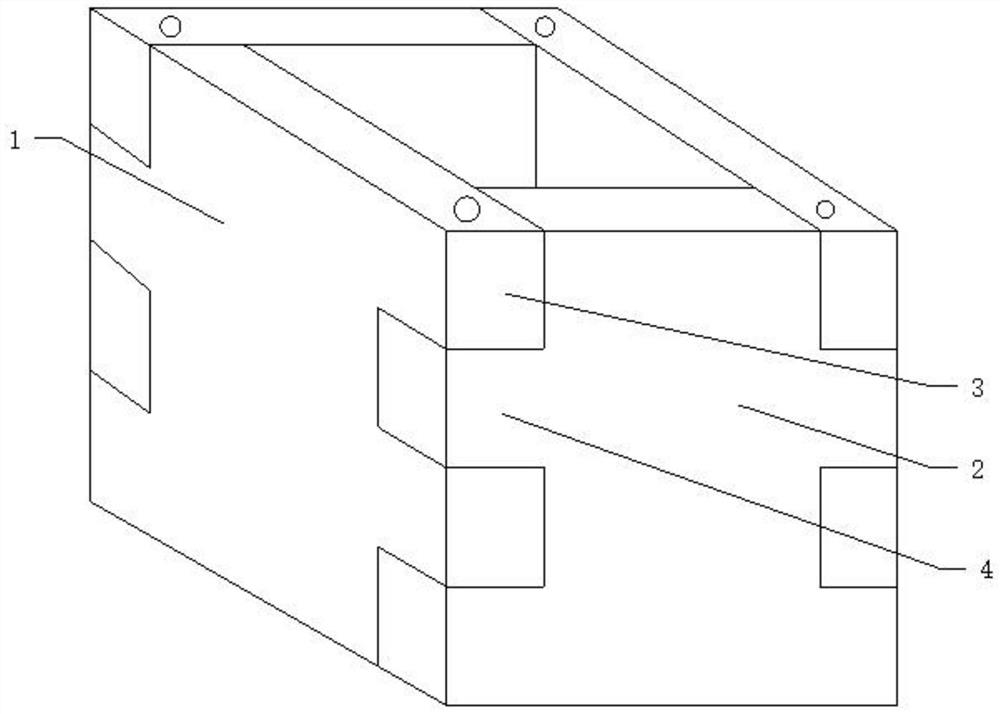

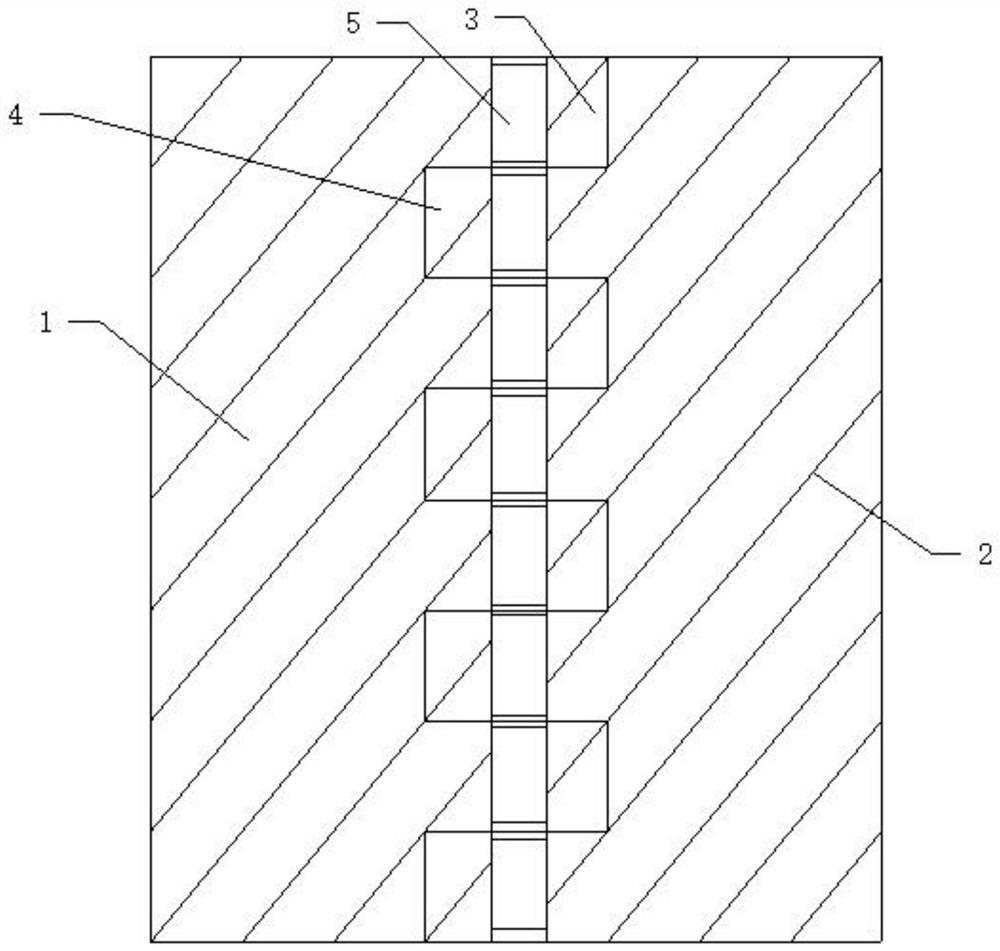

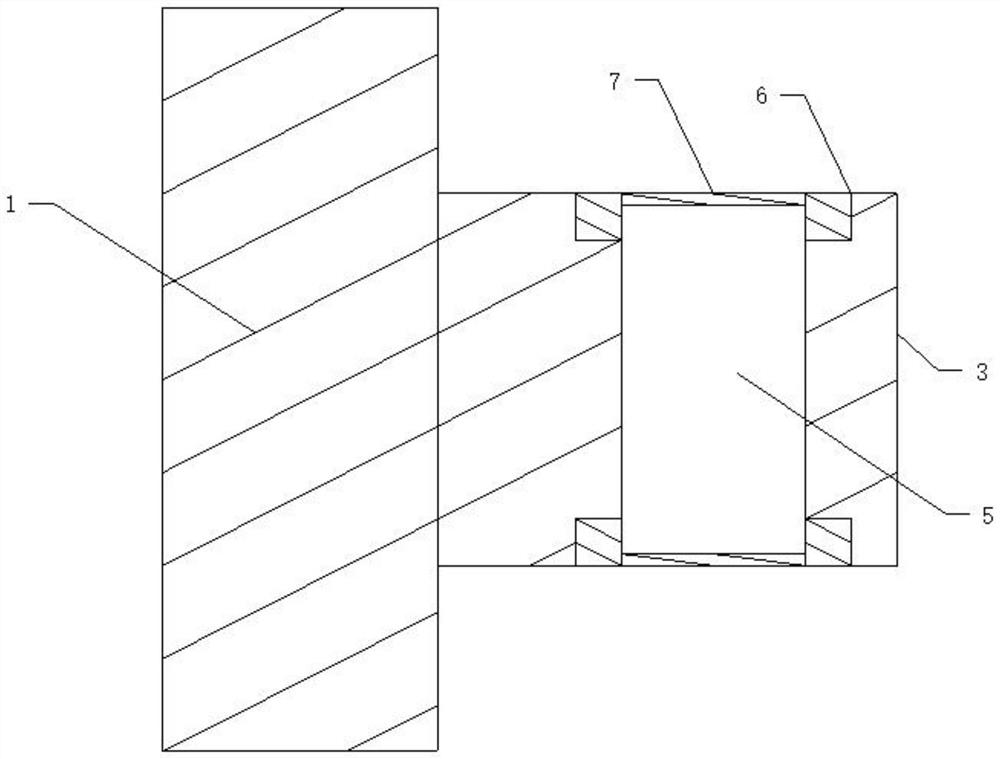

[0026] Such as Figure 1 to 4 Distance Figure 1 to 4 For the first structural schematic, a cement prefabricated mounting member includes a first prefabricating member 1, and a first prefabricating member 1 is provided with a first card block 3, further comprising a second pre-forming splicing member 2, The second prefabricated splicing member 2 is provided with a second card block 4, the first card block 3, and the second card block 1 side corresponding setting, the first card block 3 and the second card block 4 intersect Set, the first engaging block 3 and the second card block 4 are respectively provided with a corresponding first pairing hole 5, and both ends of the first pair of holes 5 are respectively provided with a sealing film 7, which is respectively. The first pair of joint holes 5 is provided with a cement, and the first card block 3 and the second block 4 are coupled, and the first pairing hole 5 corresponds to the connection, and includes one and the first docking. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com