Storage space allocation method for multi-storey shuttle car automatic storage system

A warehousing system and cargo space allocation technology, applied in the field of logistics, can solve problems such as the inability to adapt to the automatic storage system of multi-storey shuttle vehicles, and achieve the effect of improving the utilization rate of cargo spaces and the efficiency of entry and exit operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the invention includes the following methods:

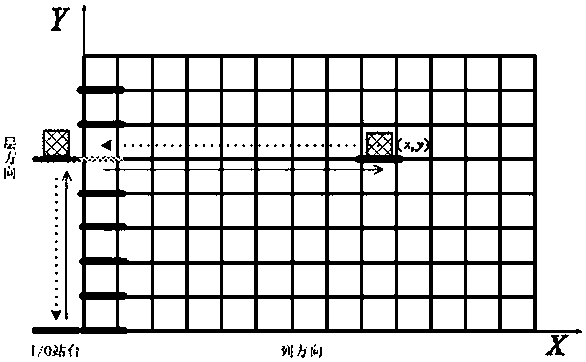

[0036] 1. By storing the location information, roadway information, and shuttle vehicle configuration data in the storage environment into the database, the warehouse layout data points are generated;

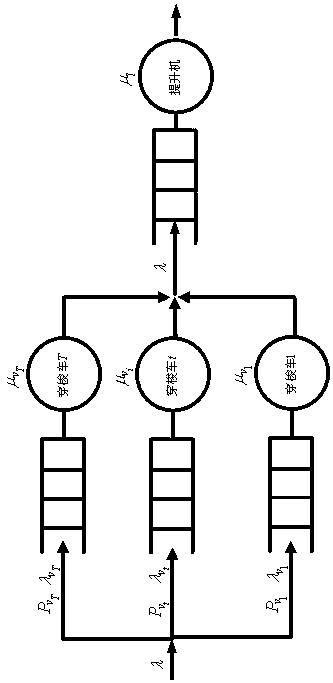

[0037] 2. Treat hoists and shuttles as service organizations, outbound tasks as customers, and establish a non-productive queuing network (such as image 3 Shown) model and solve it;

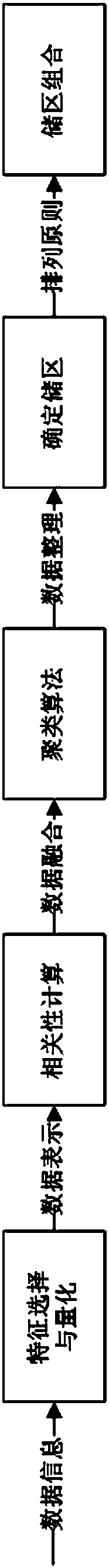

[0038] 3. According to the correlation between outbound goods, establish a correlation matrix between items, use ant colony clustering algorithm to solve item clustering, and obtain the number and shape of partitions;

[0039] 4. In the two-dimensional plane (single row of shelves), the storage areas are arranged and combined according to certain principles, and the internal storage areas are randomly stored, so as to solve the dynamic allocation optimization problem of the multi-storey shuttle car automatic storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com