Large-scale production and preparation method for Lanzhou stretched noodles

A large-scale noodle technology, which is applied in the large-scale production and preparation of Lanzhou ramen noodles, can solve the problems of lack of toughness and elasticity, questionable health, soft and sticky taste, etc., and achieve the effect of maintaining palatability, extending shelf life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

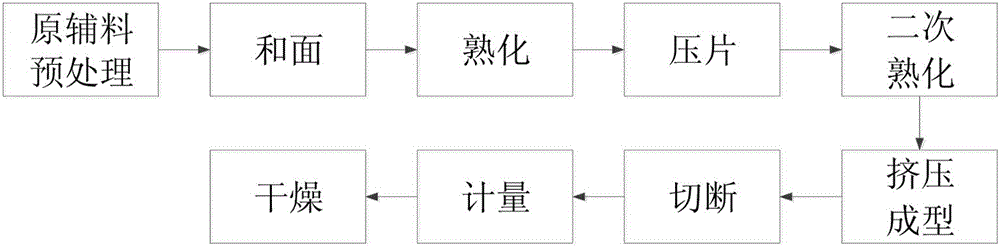

[0030] Such as figure 1 Shown is the flow chart of the large-scale production and preparation method of Lanzhou hand-pulled noodles, including the main processes of raw and auxiliary material pretreatment, dough kneading, ripening, secondary ripening, extrusion molding, cutting, metering, and drying.

[0031] Lanzhou hand-pulled noodle noodles large-scale production preparation method concrete steps of the present invention are as follows:

[0032] 1. Pretreatment process: Grind the local wheat in Gaolan County to achieve the following indicators: ash content 0.7, water content 13%, gluten content 29, stabilization time 5 minutes, coarseness reaches CB30 and passes through, and CB36 retention is less than 10%. Fucang for 3 weeks. Fu storage time is generally 2-4 weeks, the gluten has better elasticity and extensibility, and better water absorption.

[0033] 2. Kneading dough: The mass parts of raw materials during dough kneading are: 100 parts by weight of wheat flour, 1 par...

Embodiment 2

[0041] Lanzhou hand-pulled noodle noodles large-scale production preparation method concrete steps of the present invention are as follows:

[0042] 1. Pretreatment process: Grind the local wheat in Gaolan County to achieve the following indicators: ash content 0.6, water content 13.5%, gluten content 30, stabilization time 5 minutes, coarseness reaches CB30, and CB36 retention is less than 10%. Fucang for 2 weeks.

[0043] 2. Kneading dough: The mass parts of raw materials during dough kneading are: 90 parts by weight of wheat flour, 0.5 parts by weight of edible alkali, and 28 parts by weight of water. The temperature of the dough mixing water is 28°C, and it is operated in the dough mixer for 16 minutes.

[0044] 3. Curing: Carry out in a curing machine, the curing process takes 20 minutes, and the temperature is kept at 33°C.

[0045] 4. Secondary curing: Press the matured dough into a 5 mm thick dough strip, and slowly rotate it in the curing machine for 15 minutes.

...

Embodiment 3

[0050] Lanzhou hand-pulled noodle noodles large-scale production preparation method concrete steps of the present invention are as follows:

[0051] 1. Pretreatment process: Grind the local wheat in Gaolan County to achieve the following indicators: ash content 0.6, water content 13%, gluten content 29, stabilization time 5 minutes, coarseness reaches CB30 and passes through, and CB36 retention is less than 10%. Fucang for 4 weeks.

[0052] 2. Kneading dough: The mass parts of raw materials during dough kneading are: 95 parts by weight of wheat flour, 1.5 parts by weight of edible alkali, and 36 parts by weight of water. The temperature of the dough mixing water is 29°C, and it is operated in the dough mixer for 18 minutes.

[0053] 3. Curing: Carry out in a curing machine, the curing process takes 22 minutes, and the temperature is kept at 28°C.

[0054] 4. Secondary curing: Press the matured dough into a 5 mm thick dough strip, and slowly rotate it in the curing machine fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com