A combined laminar fluid distribution and mixing device and its application

A mixing device and laminar fluid technology, applied in fluid mixers, mixers, chemical/physical/physicochemical processes, etc., can solve the problems of harsh working conditions, small adjustability, high maintenance costs, etc., and achieve raw material availability Strong, easy to disassemble and assemble, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

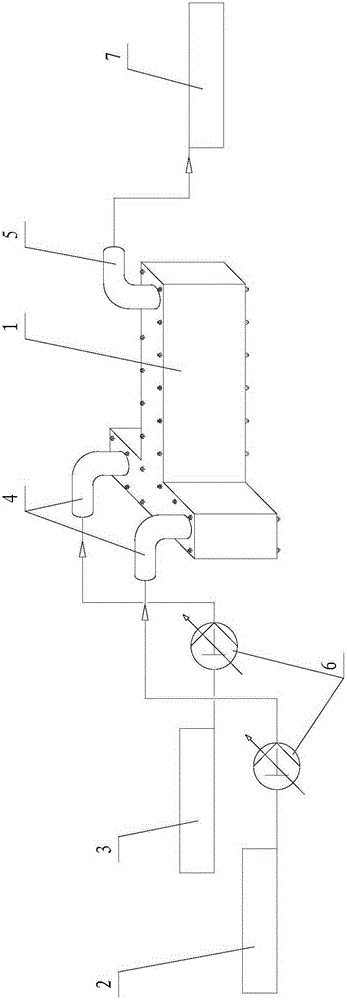

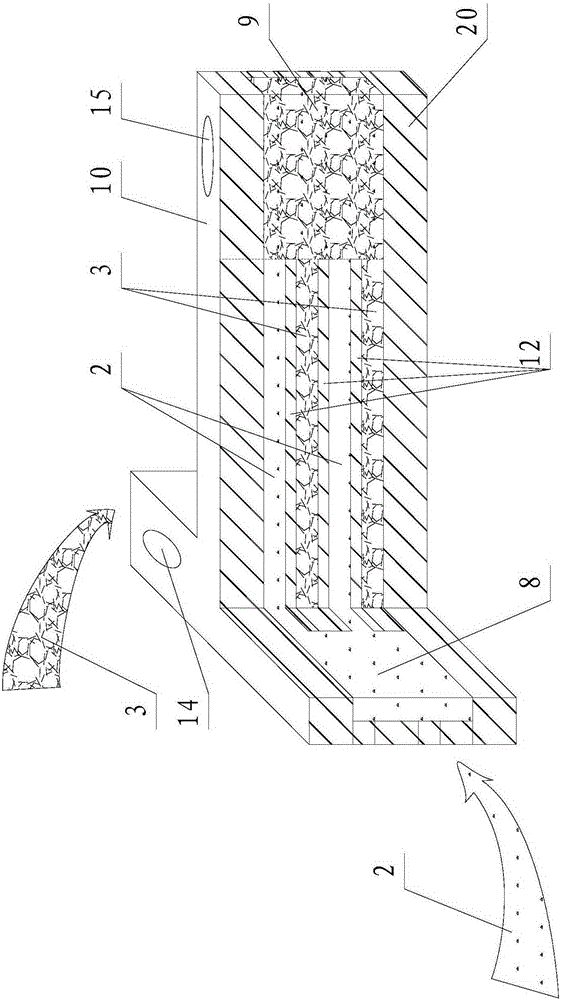

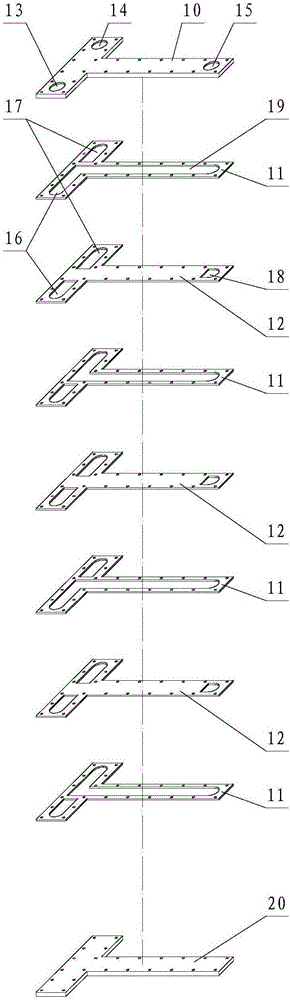

[0035] Such as figure 1 , figure 2 and image 3 As shown, in this embodiment, two fluids (fluid A and fluid B) are distributed and mixed as an example. Each layer between the cover plate 10 on the first layer and the bottom plate 20 on the bottom layer includes a plurality of splints 11 and a plurality of Partition plate 12, the quantity of clamping plate 11 and partition plate 12 can be increased or decreased arbitrarily according to the size of mixing amount. The shape and thickness of the cover plate 10, the bottom plate 20, the clamping plate 11 and the partition plate 12 in this embodiment are all the same, and the shapes are all “T” shapes. The cover plate 10 is respectively provided with a first feed port 13 and a second feed port 14 at both ends of the “T”-shaped horizontal side, and a discharge port 15 is opened at the end of the “T”-shaped vertical side of the cover plate 10. ; The first feed port 13 and the second feed port 14 are respectively connected with the...

Embodiment 2

[0039] Such as figure 1 , figure 2 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that each layer between the cover plate 10 on the first floor and the bottom plate 20 on the bottom layer is a plurality of splints 11, and the number of splints 11 can be increased arbitrarily according to the mixing amount. or reduce.

[0040] The shape and thickness of the cover plate 10 , the clamping plate 11 and the bottom plate 20 in this embodiment are all the same, and the shapes are all “T” shapes. The cover plate 10 is respectively provided with a first feed port 13 and a second feed port 14 at both ends of the “T”-shaped horizontal side, and a discharge port 15 is opened at the end of the “T”-shaped vertical side of the cover plate 10. ; The first feed port 13 and the second feed port 14 are respectively connected with the fluid A2 and the fluid B3 by the feed pipe 4, and are respectively provided with a pump 6 on the connected pipeline, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com